How to choose an industrial computer for harsh working conditions? These protective measures are key.

2026-01-23

Waterproofing, dustproofing, and shockproofing are the cornerstones of stable operation for industrial computers in harsh working environments. The internationally recognized IP protection rating is the core standard for measuring the dustproof and waterproof capabilities of equipment.

.jpg)

IP65 Protection: Completely dustproof and withstands low-pressure water jets from any direction. Suitable for outdoor environments with rainfall, but not for immersion.

IP66 Protection: Completely dustproof and can withstand strong water jets. Suitable for harsh environments such as construction sites and car washes where direct water exposure is possible.

IP67 Protection: A high-end choice for waterproofing industrial computers. Completely dustproof and can withstand immersion in one meter of water for 30 minutes without damage. This makes it suitable for unexpected water immersion scenarios such as geological exploration and emergency rescue.

2. Precision Dustproof: A Barrier Against Particle Intrusion

In dusty environments such as mines, cement plants, and wood processing plants, dust intrusion can lead to poor heat dissipation and short circuits in interfaces. Dustproof design is crucial for industrial computers:

Labyrinth Structure: Specially designed gaps in the chassis increase the difficulty for dust to enter.

Ultra-fine Dust Filter: Covers all ventilation holes, effectively blocking fine dust particles.

Sealed Interfaces: USB, Ethernet, and other interfaces are equipped with waterproof covers and sealing rings, providing comprehensive protection.

3. Drop and Shock Resistance: Robust Structural Protection

Equipped with a thickened metal structure and internal cushioning design (such as a hard drive shock absorber), it can withstand accidental drops and continuous vibrations during operation, ensuring stable operation in scenarios such as moving vehicles and production lines.

Special protection requirements for professional environments

In addition to basic "three-proof" protection, some special working conditions place higher demands on industrial computers.

Outdoor work often involves direct sunlight, and an unclear screen can severely impact efficiency. Therefore, industrial panel PCs should possess the following features:

High-Brightness Screen: At least 500 cd/m² (nits), with high-end models reaching 800-1000 nits, ensuring clear visibility in strong light.

Anti-Glare Coating: Reduces light reflection, improving visual comfort and readability.

In areas such as substations and welding workshops, strong electromagnetic interference can cause equipment malfunctions and data errors. Electromagnetic protection solutions for industrial computers include:

Internal Shielding: The motherboard and critical components are equipped with metal shielding covers, and interfaces are equipped with ESD (electrostatic discharge) protection circuits.

External Isolation: The equipment should maintain a safe distance from strong interference sources; if necessary, metal shielding barriers should be installed.

Harsh environments experience extreme temperature fluctuations. High-quality ruggedized industrial PCs possess wide temperature range capabilities (e.g., -20℃ to 60℃), allowing them to operate normally in cold storage warehouses or high-temperature workshops in steel mills without the need for air conditioning.

The protective capabilities of industrial computers are reflected in their detailed design:

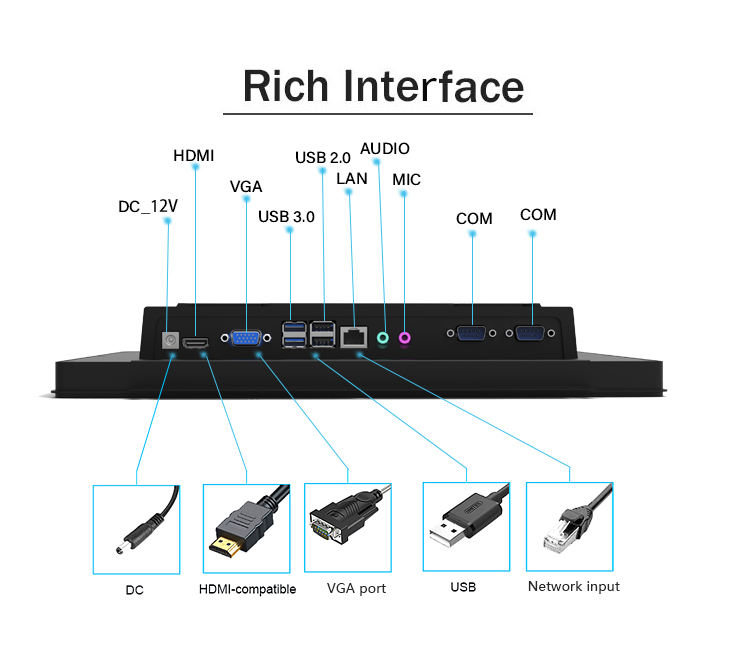

Interface Sealing: Utilizing an openable waterproof cover and silicone sealing rings for multiple layers of protection.

Chassis Materials: Employing high-strength, corrosion-resistant materials such as magnesium-aluminum alloy.

Industry Verification: Selecting brands with numerous successful cases in industries such as power line inspection, railways, and outdoor engineering. Their protective designs have been proven in practice, ensuring higher reliability.

When selecting an industrial PC for your work environment, refer to the following checklist:

Identify the primary threats: Is it water, dust, impact, magnetism, or extreme temperatures?

Confirm the IP rating: Choose IP65, IP66, or IP67 based on the actual application environment.

Check screen specifications: For outdoor use, always choose a high-brightness (≥500 nits) anti-glare screen.

Inquire about electromagnetic compatibility: In strong electromagnetic environments, always confirm that the equipment has EMC/ESD protection.

Industry case studies: Used in power line inspection, outdoor construction management, substation commissioning, and high-humidity environment inspections, etc.

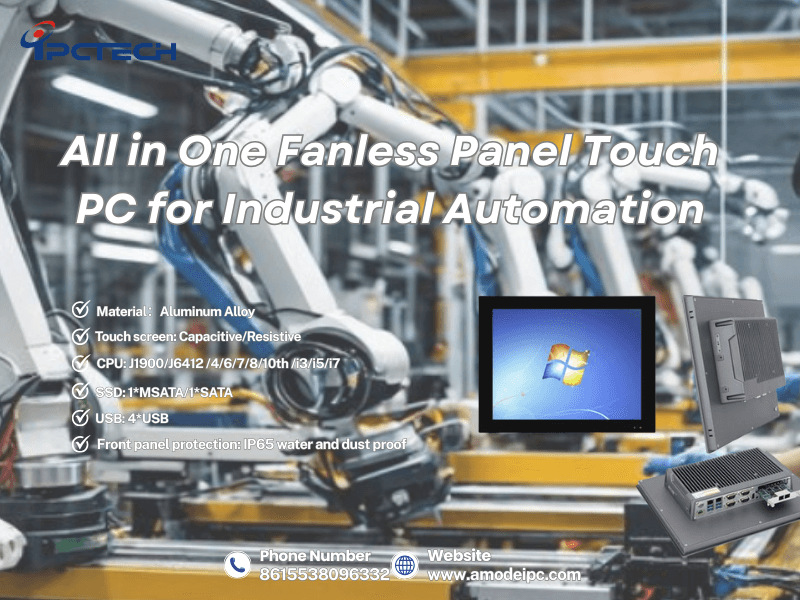

The protection rating of industrial PCs is crucial for protecting your investment and production efficiency. IPCTECH, an industry leader, provides a full range of high-protection-rating industrial PCs and panel PC solutions. Our products undergo rigorous testing and are widely used in core sectors such as power, transportation, and manufacturing.

.jpg)

1. Understanding IP Protection Ratings: Key Indicators for Water and Dust Resistance

IP65 Protection: Completely dustproof and withstands low-pressure water jets from any direction. Suitable for outdoor environments with rainfall, but not for immersion.

IP66 Protection: Completely dustproof and can withstand strong water jets. Suitable for harsh environments such as construction sites and car washes where direct water exposure is possible.

IP67 Protection: A high-end choice for waterproofing industrial computers. Completely dustproof and can withstand immersion in one meter of water for 30 minutes without damage. This makes it suitable for unexpected water immersion scenarios such as geological exploration and emergency rescue.

2. Precision Dustproof: A Barrier Against Particle Intrusion

In dusty environments such as mines, cement plants, and wood processing plants, dust intrusion can lead to poor heat dissipation and short circuits in interfaces. Dustproof design is crucial for industrial computers:

Labyrinth Structure: Specially designed gaps in the chassis increase the difficulty for dust to enter.

Ultra-fine Dust Filter: Covers all ventilation holes, effectively blocking fine dust particles.

Sealed Interfaces: USB, Ethernet, and other interfaces are equipped with waterproof covers and sealing rings, providing comprehensive protection.

3. Drop and Shock Resistance: Robust Structural Protection

Equipped with a thickened metal structure and internal cushioning design (such as a hard drive shock absorber), it can withstand accidental drops and continuous vibrations during operation, ensuring stable operation in scenarios such as moving vehicles and production lines.

Special protection requirements for professional environments

In addition to basic "three-proof" protection, some special working conditions place higher demands on industrial computers.

1. Clear Visibility in Strong Light: High-Brightness Anti-Glare Screen

Outdoor work often involves direct sunlight, and an unclear screen can severely impact efficiency. Therefore, industrial panel PCs should possess the following features:

High-Brightness Screen: At least 500 cd/m² (nits), with high-end models reaching 800-1000 nits, ensuring clear visibility in strong light.

Anti-Glare Coating: Reduces light reflection, improving visual comfort and readability.

2. Combating Strong Electromagnetic Interference: Shielding Protection Ensures Stability

In areas such as substations and welding workshops, strong electromagnetic interference can cause equipment malfunctions and data errors. Electromagnetic protection solutions for industrial computers include:

Internal Shielding: The motherboard and critical components are equipped with metal shielding covers, and interfaces are equipped with ESD (electrostatic discharge) protection circuits.

External Isolation: The equipment should maintain a safe distance from strong interference sources; if necessary, metal shielding barriers should be installed.

3. Wide Temperature Range: Coping with Extreme Cold and Heat

Harsh environments experience extreme temperature fluctuations. High-quality ruggedized industrial PCs possess wide temperature range capabilities (e.g., -20℃ to 60℃), allowing them to operate normally in cold storage warehouses or high-temperature workshops in steel mills without the need for air conditioning.

Protection Technology and Industry Verification

The protective capabilities of industrial computers are reflected in their detailed design:

Interface Sealing: Utilizing an openable waterproof cover and silicone sealing rings for multiple layers of protection.

Chassis Materials: Employing high-strength, corrosion-resistant materials such as magnesium-aluminum alloy.

Industry Verification: Selecting brands with numerous successful cases in industries such as power line inspection, railways, and outdoor engineering. Their protective designs have been proven in practice, ensuring higher reliability.

How to Choose an Industrial PC for Harsh Environments?

When selecting an industrial PC for your work environment, refer to the following checklist:

Identify the primary threats: Is it water, dust, impact, magnetism, or extreme temperatures?

Confirm the IP rating: Choose IP65, IP66, or IP67 based on the actual application environment.

Check screen specifications: For outdoor use, always choose a high-brightness (≥500 nits) anti-glare screen.

Inquire about electromagnetic compatibility: In strong electromagnetic environments, always confirm that the equipment has EMC/ESD protection.

Industry case studies: Used in power line inspection, outdoor construction management, substation commissioning, and high-humidity environment inspections, etc.

The protection rating of industrial PCs is crucial for protecting your investment and production efficiency. IPCTECH, an industry leader, provides a full range of high-protection-rating industrial PCs and panel PC solutions. Our products undergo rigorous testing and are widely used in core sectors such as power, transportation, and manufacturing.

Recommended