Can industrial PCs replace PLCs?

2025-11-11

In terms of control functions, computers can generally do everything that PLCs can do, and sometimes computers can do it even better. Industrial PCs can partially replace PLCs in certain industrial control scenarios, but there are significant differences between the two in terms of functional positioning, reliability, and cost, and the choice should be made based on specific needs.

Functional Positioning Differences: PLCs are designed specifically for industrial control. Their core functions are logic control (such as ladder diagram programming), real-time response, and anti-interference capabilities. They are suitable for handling basic control tasks such as switching quantities, timers, and counters.

Reliability and Environmental Adaptability

PLCs employ industrial-grade designs (such as fanless operation, wide temperature range, dust and water resistance), enabling stable operation in harsh environments with strong electromagnetic interference and vibration, achieving a mean time between failures (MTBF) of over 20,000 hours.

Cost and Maintenance

PLCs have lower costs, are easy to maintain, and have a low learning curve for ladder logic programming, making them suitable for small to medium-sized control projects.

Industrial PCs are more expensive and require professional maintenance, making them suitable for scenarios requiring complex calculations or human-machine interaction.

Application

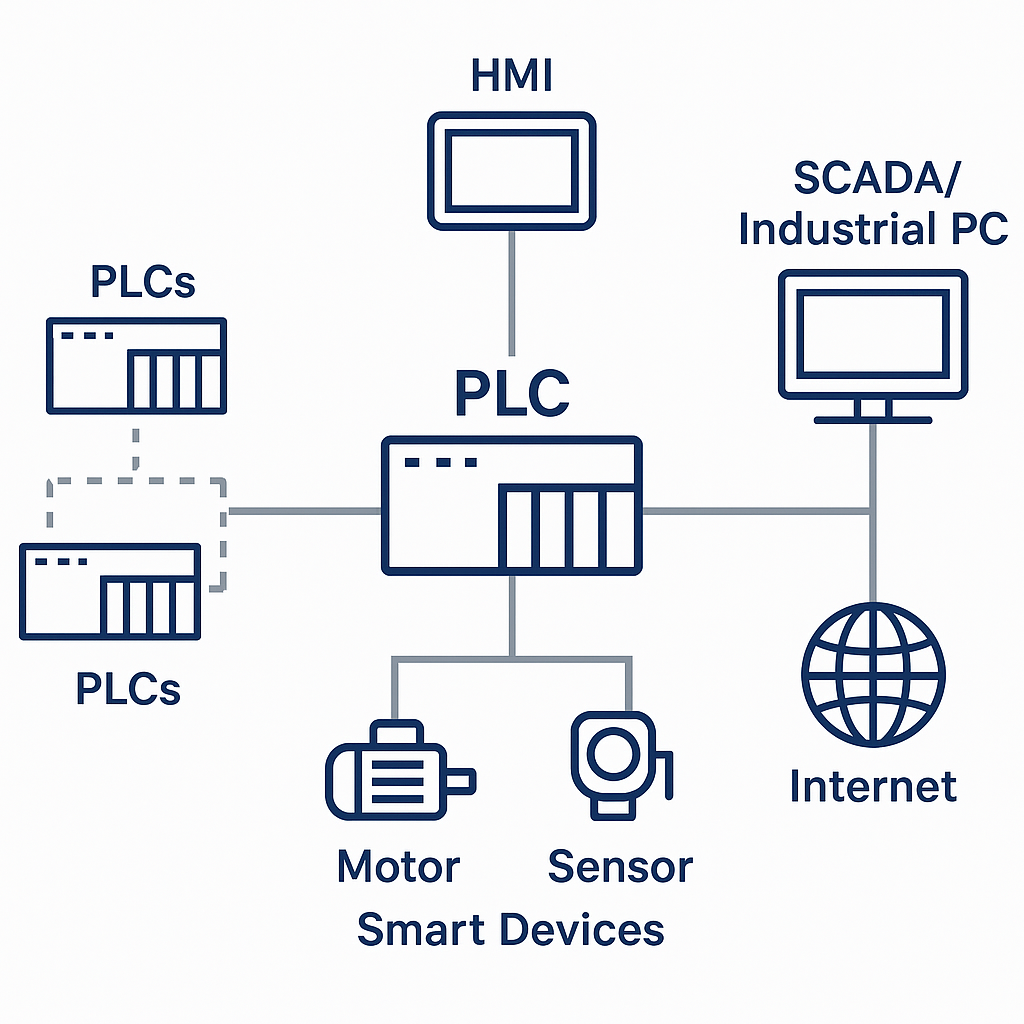

PLC: Used in applications requiring high real-time performance and reliability, such as production line control, equipment interlocking, and safety protection.

Industrial PC: Used in applications requiring high-performance computing, such as data acquisition, visual inspection, and distributed control; often used in conjunction with PLC.

Technology Trends: Some high-end industrial PCs (such as PC-based automation systems) have been used in complex control applications such as automobile manufacturing and smart factories, but modular design and redundant configurations are needed to improve reliability.

The B5300 embedded fanless industrial PC uses low-power Intel® Celeron/Atom/Core processors, ensuring stable performance.

It operates 24/7, maintaining stable operation even in unstable environments, meeting the needs of various commercial, automated, and unattended equipment. In certain situations, it can completely replace PLC-based industrial control equipment.

Industrial PCs and PLCs each have their unique advantages and applications in industrial automation. In the future, they may show a trend of convergence, but the possibility of one completely replacing the other is small.

Since its introduction into military industrial automation in the early 1990s, industrial PCs have been steadily penetrating various fields and gaining widespread application. This is due to the openness of PCs, their abundant hardware, software, and human resources, their support from a broad range of engineering and technical personnel, and their familiarity to a wide audience. The application rate of PC-based (including embedded PCs) industrial control systems has grown rapidly. Major programmable logic controller (PLC) manufacturers and industrial control system integrators have also embraced the industrial PC technology approach, making PC-based industrial control technology one of the mainstream technologies at the beginning of this century.

The low cost of industrial PCs is another important factor contributing to their potential as the mainstream of industrial control automation. In traditional automation systems, basic automation is largely monopolized by PLCs and DCSs, while process and management automation are mainly composed of various high-end process computers or minicomputers. The high cost of their hardware, system software, and application software deters many companies. In the early to mid-stages of enterprise development, choosing low-cost industrial control automation is the preferred option. Furthermore, because industrial PC-based controllers have proven to be as reliable as PLCs, are easily accepted by operators and maintenance personnel, are easy to install and use, and offer advanced diagnostic functions, they provide system integrators with more flexible options. Therefore, more and more manufacturers are beginning to adopt industrial PC control solutions in parts of their production processes.

It is foreseeable that the competition between industrial PCs and PLCs will primarily focus on high-end applications, where data is complex and equipment integration is high. Looking at development trends, the future of control systems will likely lie between industrial PCs and PLCs, and signs of this convergence are already emerging. For a considerable period to come, fieldbus technology, programmable logic controllers (PLCs), and industrial PCs will complement and promote each other, but the advantages of industrial PCs will become more prominent, and their application scope will rapidly expand to all areas of industrial control.

Integrated Management and Control Systems

With the deepening penetration of Internet technology into the field of industrial control, the integration of control and management systems has become inevitable. This makes possible the long-desired goals of integrated management and control, industrial enterprise informatization, and network-based automation in the industrial automation industry. Integrated management and control allows enterprises to select the best solutions truly suited to the new economic era, thereby improving production efficiency and enhancing market competitiveness. Therefore, a new direction in the development of industrial control technology is to realize open, distributed intelligent systems through Ethernet and Web technologies, providing modular, distributed, and reusable industrial control solutions based on Ethernet and TCP/IP protocol standards. Its most important aspect is the development of network-based engineered industrial control and management software.

The construction of an integrated control system includes the integration of multiple systems and technologies. Regarding the integration of multiple systems, the first aspect is the integration of multiple systems within the field control network, which includes three integration models. The first is the integration of Fieldbus Control Systems (FCS) and Data Control Systems (DCS), where the FCS implements basic measurement and control loops, and the DCS acts as a higher-level management and coordinator to implement complex advanced control and optimization functions. The second is the integration of Fieldbus Control Systems (FCS), DCS, and PLCs, where, in situations with complex logic interlocking, the PLC and FCS implement basic measurement and control loops, and the DCS acts as a higher-level management and coordinator to implement complex advanced control and optimization functions. The third is the integration of multiple FCSs, addressing the conversion issues between different communication protocols. This involves focusing on the interoperability of different fieldbus devices and the development of unified configuration, monitoring, and software to achieve seamless integration without sacrificing or affecting the functionality and performance of each independent system. Secondly, there is the integration of management and control networks. In future enterprise management, a large amount of data will originate from the control network. Building enterprise application software systems, including real-time databases, historical databases, data publishing, data mining, model calculations, process simulation, recipe design, operational optimization, parameter monitoring, deviation analysis, and fault diagnosis, requires establishing various databases on the Internet/Web application network environment to truly achieve integrated management and control. This provides intelligent decision-making support to the control software and valuable data to the management software.

In terms of technology integration, this includes the integration of various technologies such as equipment interoperability technology, general data exchange technology, Ethernet, and industrial Ethernet. General data exchange technology includes DDE dynamic data exchange technology, NetDDE network dynamic exchange technology, ODBC open database interconnection technology, COM/DCOM component object model, and OPC technology. Ethernet+TCP/IP technology enables the direct transmission and sharing of control parameters and the status of network nodes in the industrial field within the enterprise information network, thus avoiding the difficulties in integrating PLCs, DCSs, and FCSs due to the existence of multiple protocols.

Functional Positioning Differences: PLCs are designed specifically for industrial control. Their core functions are logic control (such as ladder diagram programming), real-time response, and anti-interference capabilities. They are suitable for handling basic control tasks such as switching quantities, timers, and counters.

Reliability and Environmental Adaptability

PLCs employ industrial-grade designs (such as fanless operation, wide temperature range, dust and water resistance), enabling stable operation in harsh environments with strong electromagnetic interference and vibration, achieving a mean time between failures (MTBF) of over 20,000 hours.

Cost and Maintenance

PLCs have lower costs, are easy to maintain, and have a low learning curve for ladder logic programming, making them suitable for small to medium-sized control projects.

Industrial PCs are more expensive and require professional maintenance, making them suitable for scenarios requiring complex calculations or human-machine interaction.

Application

PLC: Used in applications requiring high real-time performance and reliability, such as production line control, equipment interlocking, and safety protection.

Industrial PC: Used in applications requiring high-performance computing, such as data acquisition, visual inspection, and distributed control; often used in conjunction with PLC.

Technology Trends: Some high-end industrial PCs (such as PC-based automation systems) have been used in complex control applications such as automobile manufacturing and smart factories, but modular design and redundant configurations are needed to improve reliability.

The B5300 embedded fanless industrial PC uses low-power Intel® Celeron/Atom/Core processors, ensuring stable performance.

It operates 24/7, maintaining stable operation even in unstable environments, meeting the needs of various commercial, automated, and unattended equipment. In certain situations, it can completely replace PLC-based industrial control equipment.

Industrial PCs and PLCs each have their unique advantages and applications in industrial automation. In the future, they may show a trend of convergence, but the possibility of one completely replacing the other is small.

Industrial PC Development

Since its introduction into military industrial automation in the early 1990s, industrial PCs have been steadily penetrating various fields and gaining widespread application. This is due to the openness of PCs, their abundant hardware, software, and human resources, their support from a broad range of engineering and technical personnel, and their familiarity to a wide audience. The application rate of PC-based (including embedded PCs) industrial control systems has grown rapidly. Major programmable logic controller (PLC) manufacturers and industrial control system integrators have also embraced the industrial PC technology approach, making PC-based industrial control technology one of the mainstream technologies at the beginning of this century.

The low cost of industrial PCs is another important factor contributing to their potential as the mainstream of industrial control automation. In traditional automation systems, basic automation is largely monopolized by PLCs and DCSs, while process and management automation are mainly composed of various high-end process computers or minicomputers. The high cost of their hardware, system software, and application software deters many companies. In the early to mid-stages of enterprise development, choosing low-cost industrial control automation is the preferred option. Furthermore, because industrial PC-based controllers have proven to be as reliable as PLCs, are easily accepted by operators and maintenance personnel, are easy to install and use, and offer advanced diagnostic functions, they provide system integrators with more flexible options. Therefore, more and more manufacturers are beginning to adopt industrial PC control solutions in parts of their production processes.

It is foreseeable that the competition between industrial PCs and PLCs will primarily focus on high-end applications, where data is complex and equipment integration is high. Looking at development trends, the future of control systems will likely lie between industrial PCs and PLCs, and signs of this convergence are already emerging. For a considerable period to come, fieldbus technology, programmable logic controllers (PLCs), and industrial PCs will complement and promote each other, but the advantages of industrial PCs will become more prominent, and their application scope will rapidly expand to all areas of industrial control.

Integrated Management and Control Systems

With the deepening penetration of Internet technology into the field of industrial control, the integration of control and management systems has become inevitable. This makes possible the long-desired goals of integrated management and control, industrial enterprise informatization, and network-based automation in the industrial automation industry. Integrated management and control allows enterprises to select the best solutions truly suited to the new economic era, thereby improving production efficiency and enhancing market competitiveness. Therefore, a new direction in the development of industrial control technology is to realize open, distributed intelligent systems through Ethernet and Web technologies, providing modular, distributed, and reusable industrial control solutions based on Ethernet and TCP/IP protocol standards. Its most important aspect is the development of network-based engineered industrial control and management software.

The construction of an integrated control system includes the integration of multiple systems and technologies. Regarding the integration of multiple systems, the first aspect is the integration of multiple systems within the field control network, which includes three integration models. The first is the integration of Fieldbus Control Systems (FCS) and Data Control Systems (DCS), where the FCS implements basic measurement and control loops, and the DCS acts as a higher-level management and coordinator to implement complex advanced control and optimization functions. The second is the integration of Fieldbus Control Systems (FCS), DCS, and PLCs, where, in situations with complex logic interlocking, the PLC and FCS implement basic measurement and control loops, and the DCS acts as a higher-level management and coordinator to implement complex advanced control and optimization functions. The third is the integration of multiple FCSs, addressing the conversion issues between different communication protocols. This involves focusing on the interoperability of different fieldbus devices and the development of unified configuration, monitoring, and software to achieve seamless integration without sacrificing or affecting the functionality and performance of each independent system. Secondly, there is the integration of management and control networks. In future enterprise management, a large amount of data will originate from the control network. Building enterprise application software systems, including real-time databases, historical databases, data publishing, data mining, model calculations, process simulation, recipe design, operational optimization, parameter monitoring, deviation analysis, and fault diagnosis, requires establishing various databases on the Internet/Web application network environment to truly achieve integrated management and control. This provides intelligent decision-making support to the control software and valuable data to the management software.

In terms of technology integration, this includes the integration of various technologies such as equipment interoperability technology, general data exchange technology, Ethernet, and industrial Ethernet. General data exchange technology includes DDE dynamic data exchange technology, NetDDE network dynamic exchange technology, ODBC open database interconnection technology, COM/DCOM component object model, and OPC technology. Ethernet+TCP/IP technology enables the direct transmission and sharing of control parameters and the status of network nodes in the industrial field within the enterprise information network, thus avoiding the difficulties in integrating PLCs, DCSs, and FCSs due to the existence of multiple protocols.

Recommended