How to choose an industrial computer?

2025-11-25

Industrial computers are becoming increasingly important in factories. They're not just user interfaces; they're the data acquisition and control center for the entire production process—truly crucial and core.

But the question arises: how do you choose the right industrial computer? What are the key considerations? Especially since these devices operate in harsh environments with high temperatures, dust, and vibration, the requirements for stability and reliability are extremely high. It's not something that can be determined by just looking at a few parameters.

Industrial computer selection is crucial for stable operation: CPU performance and efficiency, adaptability to harsh environments, edge computing to meet real-time needs, robust connectivity to integrate the Internet of Things, and SSD storage to ensure high-speed response and achieve zero downtime.

I. Technical Dimensions: Core Performance and Stability Industrial computers need to operate in harsh environments such as vibration, high temperatures, and dust for extended periods; therefore, hardware stability is paramount.

Rugged and Durable Design: Fanless designs are preferred to avoid downtime due to fan failure. The chassis should be made of aluminum alloy and meet IP65 dust and water resistance standards to withstand dust, oil, and moisture.

Wide Temperature Range: Components must support a wide operating temperature range (e.g., -20℃ to 70℃) to ensure stable startup and operation in extremely cold or hot workshop environments.

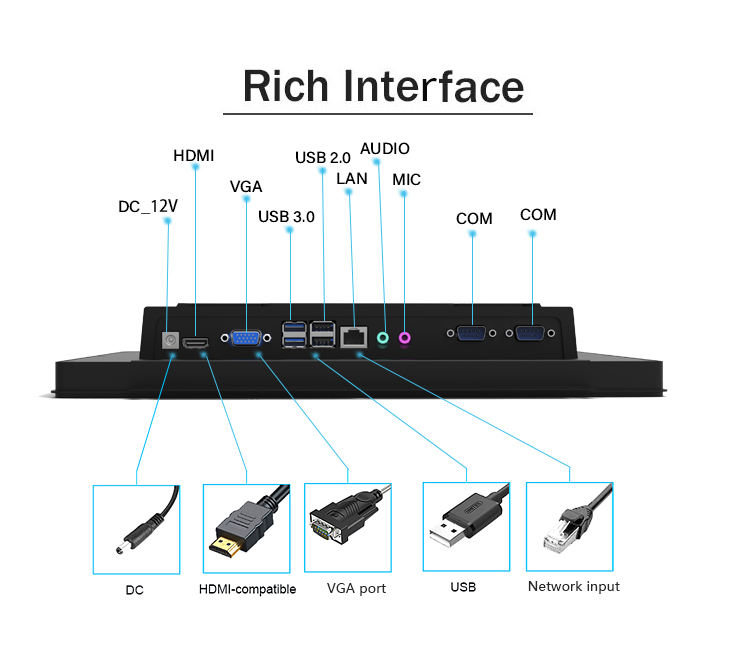

Real-Time Processing and Expansion: For scenarios requiring low-latency control, a real-time operating system (RTOS) is required. Furthermore, a rich array of interfaces is essential, such as CAN bus, RS485/232, and multiple network ports, to facilitate flexible connection to various industrial devices.

II. Precise Matching of Industries and Application Scenarios

Manufacturing (PLC/SCADA Integration): Emphasizes powerful multi-core CPU performance and high-speed I/O processing capabilities to ensure smooth interaction with the control system.

Energy Industry (Wind Power/Photovoltaic): Focuses on electromagnetic interference (EMI) immunity and reliable remote monitoring capabilities.

Rail Transportation: Must pass international industry certifications such as EN50155 to ensure reliable operation under continuous vibration and shock environments.

Equipment Form Factor Selection:

Embedded Industrial PCs: Compact and small, suitable for embedding in space-constrained devices such as robots and medical equipment. The B5300 is well-configured and suitable for various factory environments.

Industrial Panel PCs: Integrates display and touch control, ideal for production line human-machine interfaces (HMIs). The P8000 series panel PCs are recommended for their stable performance.

Rack-Mounted Industrial PCs: Suitable for centralized deployment in server racks, used as data acquisition servers, etc.

III. Industry Standards and Certifications

Compliance is crucial for selecting industrial computers.

International and Domestic Standards: Verify that the product possesses basic safety certifications such as CE, FCC, and CCC. In specific industries, compliance with professional standards such as IEC 61131-3 (Programmable Logic Controllers) and ISO 13849 (Safety of Machinery) is required.

Mandatory Industry Certifications: In heavily regulated sectors such as rail transportation and healthcare, certifications such as IRIS (railway) and FDA 510(k) (medical) are entry-level requirements and must be confirmed during the selection process.

IV. Applications

Choosing the right industrial computer depends on the applications it needs to perform. For example, industrial computers are typically deployed as workstations and HMIs (Human Machine Interfaces) in industrial environments, including manufacturing plants, food processing plants, farms, warehouses, transportation hubs, medical facilities, hazardous locations, and various other environments.

The more applications there are, the higher the software requirements, and the greater the computing power needed to ensure smooth and reliable system operation.

Due to the rapid growth and advancement of the Internet of Things (IoT), robust edge industrial computing is becoming increasingly important. This is where industrial computers come in, as some applications require data processing and analysis at the network edge. Because data does not need to be transmitted over long distances, edge computers can perform data processing, analysis, and decision-making in real time, supporting many applications that require such processing and analysis.

V. Connectivity: Ensuring Seamless System Integration

After determining computing power, environmental adaptability, and application requirements, connectivity becomes a crucial aspect of system integration. Robust connectivity is fundamental for efficient collaboration between industrial computers and various sensors, network devices, and peripheral hardware. Common connectivity options include Bluetooth, Wi-Fi 6, 4G/5G cellular networks, and 10GbE LAN ports. Furthermore, modular I/O expansion capabilities further enhance system flexibility, supporting multiple interfaces including M12/RJ45 Ethernet ports, serial ports, USB, DP, and DIO, meeting the device access needs in complex scenarios.

VI. Operating System: The Software Foundation for Stable System Operation

As the core of software and hardware collaboration, the compatibility and stability of the operating system are often underestimated. To ensure stable system operation upon delivery, we strongly recommend conducting system-level testing and verification during the selection phase. We are committed to working closely with our customers to ensure that the selected operating system perfectly matches the hardware configuration and business software, achieving a highly efficient out-of-the-box experience.

VII. Power Supply Configuration: Adaptable to Diverse Power Supply Environments Industrial computers are often deployed in areas with complex power environments or remote locations, making their power supply adaptability particularly crucial. Most models support wide-voltage DC power input, and some products also feature vehicle mode (12/24V DC) switching functionality, allowing direct power supply from vehicle batteries to suit mobile or field operation scenarios.

VIII. Long Lifespan and Maintainability: Ensuring Continuous Operation

In industrial applications, the long-term reliable operation of equipment is crucial. To avoid maintenance interruptions due to the shutdown of core components, suppliers committing to long-term supply (typically 5 to 10 years) should be prioritized during the selection process. Modular design also significantly improves equipment maintainability. For example, the use of quickly replaceable screens, batteries, storage modules, and dedicated interfaces enables precise repairs in case of component failure, significantly reducing downtime and lifespan costs. Comprehensive after-sales spare parts support and a professional technical service team are essential safeguards for ensuring stable operation throughout the equipment's entire lifespan.

IX. Supplier Strength and Service: Professional Support Guarantees Project Success

The supplier's overall strength and service quality directly impact the project's implementation effectiveness and long-term maintenance experience. During the selection process, it is recommended to focus on their extensive experience in the industrial field, successful case studies in their industry, customer reputation, and their pre-sales consulting and solution design capabilities. Furthermore, the ability to provide timely and professional after-sales technical support (such as 24/7 response time and on-site service) should also be a key evaluation indicator.

Cost Considerations: Emphasizing Total Cost of Ownership (TCO)

In selecting industrial computers, the "lowest price only" mentality should be abandoned, and a comprehensive evaluation of total cost of ownership should be conducted. In addition to the initial purchase cost, the following hidden costs and long-term benefits should be considered:

Downtime Losses: Production interruptions and order delays caused by equipment failure can result in losses far exceeding the value of the equipment itself.

Maintenance Costs: Including repair fees, spare parts procurement, and labor costs.

Replacement Costs: System reconstruction costs due to premature equipment shutdown or technological obsolescence.

Efficiency and Security Benefits: Suitable equipment can improve operational efficiency, reduce errors, and enhance security, thereby creating long-term value.

But the question arises: how do you choose the right industrial computer? What are the key considerations? Especially since these devices operate in harsh environments with high temperatures, dust, and vibration, the requirements for stability and reliability are extremely high. It's not something that can be determined by just looking at a few parameters.

Industrial computer selection is crucial for stable operation: CPU performance and efficiency, adaptability to harsh environments, edge computing to meet real-time needs, robust connectivity to integrate the Internet of Things, and SSD storage to ensure high-speed response and achieve zero downtime.

I. Technical Dimensions: Core Performance and Stability Industrial computers need to operate in harsh environments such as vibration, high temperatures, and dust for extended periods; therefore, hardware stability is paramount.

Rugged and Durable Design: Fanless designs are preferred to avoid downtime due to fan failure. The chassis should be made of aluminum alloy and meet IP65 dust and water resistance standards to withstand dust, oil, and moisture.

Wide Temperature Range: Components must support a wide operating temperature range (e.g., -20℃ to 70℃) to ensure stable startup and operation in extremely cold or hot workshop environments.

Real-Time Processing and Expansion: For scenarios requiring low-latency control, a real-time operating system (RTOS) is required. Furthermore, a rich array of interfaces is essential, such as CAN bus, RS485/232, and multiple network ports, to facilitate flexible connection to various industrial devices.

II. Precise Matching of Industries and Application Scenarios

Manufacturing (PLC/SCADA Integration): Emphasizes powerful multi-core CPU performance and high-speed I/O processing capabilities to ensure smooth interaction with the control system.

Energy Industry (Wind Power/Photovoltaic): Focuses on electromagnetic interference (EMI) immunity and reliable remote monitoring capabilities.

Rail Transportation: Must pass international industry certifications such as EN50155 to ensure reliable operation under continuous vibration and shock environments.

Equipment Form Factor Selection:

Embedded Industrial PCs: Compact and small, suitable for embedding in space-constrained devices such as robots and medical equipment. The B5300 is well-configured and suitable for various factory environments.

Industrial Panel PCs: Integrates display and touch control, ideal for production line human-machine interfaces (HMIs). The P8000 series panel PCs are recommended for their stable performance.

Rack-Mounted Industrial PCs: Suitable for centralized deployment in server racks, used as data acquisition servers, etc.

III. Industry Standards and Certifications

Compliance is crucial for selecting industrial computers.

International and Domestic Standards: Verify that the product possesses basic safety certifications such as CE, FCC, and CCC. In specific industries, compliance with professional standards such as IEC 61131-3 (Programmable Logic Controllers) and ISO 13849 (Safety of Machinery) is required.

Mandatory Industry Certifications: In heavily regulated sectors such as rail transportation and healthcare, certifications such as IRIS (railway) and FDA 510(k) (medical) are entry-level requirements and must be confirmed during the selection process.

IV. Applications

Choosing the right industrial computer depends on the applications it needs to perform. For example, industrial computers are typically deployed as workstations and HMIs (Human Machine Interfaces) in industrial environments, including manufacturing plants, food processing plants, farms, warehouses, transportation hubs, medical facilities, hazardous locations, and various other environments.

The more applications there are, the higher the software requirements, and the greater the computing power needed to ensure smooth and reliable system operation.

Due to the rapid growth and advancement of the Internet of Things (IoT), robust edge industrial computing is becoming increasingly important. This is where industrial computers come in, as some applications require data processing and analysis at the network edge. Because data does not need to be transmitted over long distances, edge computers can perform data processing, analysis, and decision-making in real time, supporting many applications that require such processing and analysis.

V. Connectivity: Ensuring Seamless System Integration

After determining computing power, environmental adaptability, and application requirements, connectivity becomes a crucial aspect of system integration. Robust connectivity is fundamental for efficient collaboration between industrial computers and various sensors, network devices, and peripheral hardware. Common connectivity options include Bluetooth, Wi-Fi 6, 4G/5G cellular networks, and 10GbE LAN ports. Furthermore, modular I/O expansion capabilities further enhance system flexibility, supporting multiple interfaces including M12/RJ45 Ethernet ports, serial ports, USB, DP, and DIO, meeting the device access needs in complex scenarios.

VI. Operating System: The Software Foundation for Stable System Operation

As the core of software and hardware collaboration, the compatibility and stability of the operating system are often underestimated. To ensure stable system operation upon delivery, we strongly recommend conducting system-level testing and verification during the selection phase. We are committed to working closely with our customers to ensure that the selected operating system perfectly matches the hardware configuration and business software, achieving a highly efficient out-of-the-box experience.

VII. Power Supply Configuration: Adaptable to Diverse Power Supply Environments Industrial computers are often deployed in areas with complex power environments or remote locations, making their power supply adaptability particularly crucial. Most models support wide-voltage DC power input, and some products also feature vehicle mode (12/24V DC) switching functionality, allowing direct power supply from vehicle batteries to suit mobile or field operation scenarios.

VIII. Long Lifespan and Maintainability: Ensuring Continuous Operation

In industrial applications, the long-term reliable operation of equipment is crucial. To avoid maintenance interruptions due to the shutdown of core components, suppliers committing to long-term supply (typically 5 to 10 years) should be prioritized during the selection process. Modular design also significantly improves equipment maintainability. For example, the use of quickly replaceable screens, batteries, storage modules, and dedicated interfaces enables precise repairs in case of component failure, significantly reducing downtime and lifespan costs. Comprehensive after-sales spare parts support and a professional technical service team are essential safeguards for ensuring stable operation throughout the equipment's entire lifespan.

IX. Supplier Strength and Service: Professional Support Guarantees Project Success

The supplier's overall strength and service quality directly impact the project's implementation effectiveness and long-term maintenance experience. During the selection process, it is recommended to focus on their extensive experience in the industrial field, successful case studies in their industry, customer reputation, and their pre-sales consulting and solution design capabilities. Furthermore, the ability to provide timely and professional after-sales technical support (such as 24/7 response time and on-site service) should also be a key evaluation indicator.

Cost Considerations: Emphasizing Total Cost of Ownership (TCO)

In selecting industrial computers, the "lowest price only" mentality should be abandoned, and a comprehensive evaluation of total cost of ownership should be conducted. In addition to the initial purchase cost, the following hidden costs and long-term benefits should be considered:

Downtime Losses: Production interruptions and order delays caused by equipment failure can result in losses far exceeding the value of the equipment itself.

Maintenance Costs: Including repair fees, spare parts procurement, and labor costs.

Replacement Costs: System reconstruction costs due to premature equipment shutdown or technological obsolescence.

Efficiency and Security Benefits: Suitable equipment can improve operational efficiency, reduce errors, and enhance security, thereby creating long-term value.

Recommended