Best Panel PCs for Outdoor or Harsh Industrial Environments

2025-09-29

In industrial production and outdoor work environments, the challenges equipment faces are far more severe than we imagine. Picture this: at an Arctic research station where temperatures plummet to -30°C, a standard laptop freezes the moment it boots up; at a dust-filled mining site, the ventilation ports of a consumer-grade tablet quickly become clogged, eventually shutting down due to overheating; In food processing plants requiring frequent rinsing, water ingress causes short circuits that halt production lines immediately. These aren't extreme scenarios—they're real operational challenges faced daily by countless enterprises.

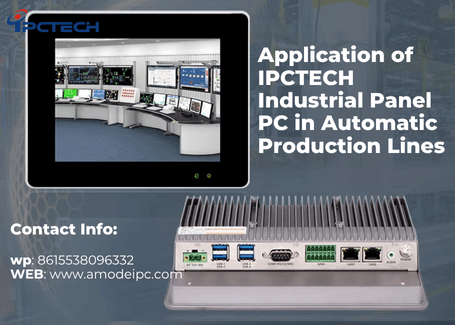

Consumer-grade computers are designed for “comfortable indoor environments.” When confronted with extreme temperatures, dust, moisture, vibration, and impact—pressures unique to industrial settings—they often fail miserably. Industrial Panel PCs, however, are computing devices engineered for harsh environments, becoming critical for maintaining production continuity and ensuring operational efficiency. With 15 years of deep expertise in industrial computing, IPCTech has consistently centered its R&D philosophy on “stable operation in extreme conditions.” Its industrial panel PCs not only meet multiple stringent global certifications but also deliver premium automation solutions to clients across petrochemical, mining, construction, and food processing sectors.

The “ruggedness” of industrial equipment hinges on whether it has passed authoritative certifications—an industry-recognized “hard threshold.” The most prevalent global certification systems include IP protection ratings, NEMA protection standards, and IEC (International Electrotechnical Commission) standards. These define a device's environmental adaptability across three dimensions: “dust and water resistance,” “corrosion and impact resistance,” and “temperature and vibration tolerance.”

• IP Rating: Primarily focuses on “dustproofing” and “waterproofing” capabilities. For outdoor and industrial settings, a minimum IP65 rating (complete dust protection, withstands low-pressure water jets) is required. Environments involving frequent washing (e.g., food processing, car washes) demand IP67 (short-term immersion resistance) or IP69K (high-pressure/high-temperature water jet resistance). All ipctech industrial tablets come standard with IP65 or higher ratings.

IEC Standards: Core evaluation focuses on “temperature and vibration stability.” IEC 60068-2-1 addresses low-temperature environments, IEC 60068-2-2 covers high-temperature conditions, and IEC 60068-2-6 specifies vibration testing. All ipctech products pass critical IEC standards, ensuring long-term reliability in extreme environments.

Extreme temperatures are the primary threat in outdoor and industrial settings. Winter outdoor sites in northern regions often drop below -20°C, causing standard computer batteries to drain rapidly and screens to crack from freezing. Meanwhile, workshop temperatures in steel mills and glass factories can exceed 60°C, forcing computer processors to throttle down due to overheating or even burning out motherboards.

The temperature resilience of industrial tablets hinges on two factors: operating temperature range and thermal management system:

• Operating Temperature Range: Premium industrial tablets should cover the standard extreme range of -30°C to 70°C. Specialized scenarios (e.g., Arctic expeditions, desert oil fields) require coverage from -40°C to 75°C. For low-temperature environments, iPCTech developed “Active Heating Technology.” Below -20°C, the device automatically activates internal heating modules to ensure battery and display functionality. For high-temperature scenarios, it employs a “Fully Enclosed Passive Cooling Design.” This utilizes an aluminum alloy casing to rapidly dissipate heat, maintaining low temperatures without fans (avoiding dust clogging).

• Thermal Management Technology: Preventing localized overheating is paramount. Optimized motherboard layout and shell heat dissipation patterns ensure even heat dispersion from core components like processors and hard drives. Even in 70°C environments, surface temperatures remain below 45°C, preventing operator burns.

In scenarios like transport vehicles (trucks, excavators), production line conveyors, and mining machinery, devices endure prolonged high-frequency vibration or sudden impacts. Standard computers use “plug-in connections” for components like hard drives and memory, where vibration causes poor contact. Sudden impacts (device drops, heavy object collisions) can directly damage screens and motherboards.

• MIL-STD Certification: This U.S. military standard for “harsh environment resistance” includes MIL-STD-810H—the most stringent version—covering tests for vibration (50–2000Hz), shock (1000G instantaneous impact), and drops (1.2m onto concrete).

• Structural Design: ipcTech employs a fanless design. Capacitive or resistive touch options are available. It offers strong anti-interference capabilities and high expandability, meeting the demands of harsh industrial environments. The aluminum alloy chassis ensures 24/7 operation in temperatures ranging from -20°C to 60°C.

For industrial tablets, internal components matter more than external appearance—hardware must ensure long-term stable operation, while software must be compatible with specialized industrial systems and tools. Otherwise, even a “rugged exterior” cannot meet practical demands.

• Hardware: Industrial-grade “core components”: ipctech employs a hardware combination of “industrial-grade motherboard + wide-temperature storage + stable power supply”:

◦ Motherboard: Features Intel or AMD processors engineered for industrial environments (e.g., Intel Core i5-1135G7, AMD Ryzen 3 5300U), supporting wide-temperature operation (-40°C to 85°C) with fanless design (preventing dust accumulation) for over 10 years of service life.

◦ Storage: Utilizes wide-temperature SSDs (-40°C to 85°C), which withstand higher vibration and shock than standard SSDs while delivering more stable read/write speeds (sequential read/write ≥500MB/s), preventing data loss due to storage failures.

◦ Power Supply: Equipped with a “wide-voltage power module” (input voltage 9–36V DC) to adapt to voltage fluctuations in industrial environments. Features overvoltage, overcurrent, and short-circuit protection to prevent device damage from power issues.

• Software: Compatible with the “Industrial Ecosystem”: IPCTech industrial tablets support mainstream industrial operating systems and software:

◦ Operating Systems: Pre-installed with Windows 10 IoT Enterprise and Linux, ensuring long-term system stability without frequent upgrades.

Software Compatibility: Seamlessly supports SCADA, MES, and IoT monitoring tools, enabling integration with a wide range of industrial equipment.

• Question 1: What environmental threats will the device face?

List specific environmental factors:

Temperature range (e.g., “Winter -15°C to Summer 45°C,” " Constant workshop temperature 60℃“), humidity/moisture conditions (e.g., ”Daily high-pressure washing,“ ”High-salt marine environment“), dust concentration (e.g., ”Heavy dust in mining,“ ”Light dust in standard workshops“), vibration/impact intensity (e.g., ”Fixed installation,“ ”Mobile vehicle use,“ ”Mining machinery vibration").

•Question 2: What core functions must the device perform?

Define usage scenarios: Is it for real-time monitoring of multiple devices (requiring large-size, high-resolution screen), “mobile operation logging” (requiring long battery life, lightweight design), “basic data entry” (requiring low cost, easy operation), or “stable operation under extreme temperatures”

•Question 3: What installation and usage constraints exist?

Consider physical space, power supply, network environment, etc.

•Must-Check Parameter 1: Protection Rating

Outdoor/humid environments: IP66 or higher;

Dusty environments: IP65 or higher;

•Must-Check Parameter 2: Operating Temperature Range

Standard outdoor/industrial environments: -20°C to 60°C;

Extreme low/high-temperature environments: -30°C to 70°C, -40°C to 75°C.

• Essential Parameter 3: Hardware Stability

Prioritize “industrial-grade components”: e.g., Intel/AMD industrial-grade processors, wide-temperature SSDs, fanless design (to prevent dust clogging).

In industrial settings, “time is money” rings especially true. Equipment failures causing downtime not only result in lost production value but can also trigger chain reactions (such as order delays and customer attrition).

The “intelligence” and “compatibility” of industrial tablets significantly streamline manual operations and enhance efficiency:

• Real-time data collection: By integrating with SCADA/MES systems, ipctech tablets capture equipment performance metrics (e.g., temperature, RPM, output) in real time, eliminating manual logging.

• Remote monitoring and control: Supported by 5G/Wi-Fi networks, ipctech tablets enable remote equipment status monitoring and parameter adjustments.

• User-friendly operation: Wide-screen displays, glove-compatible touchscreens, and anti-glare designs simplify employee tasks.\

While high-quality industrial tablets have higher upfront costs, they prove more economical over the entire “procurement-use-disposal” lifecycle:

• Reduced maintenance and replacement costs: With a 5-10 year lifespan—2-3 times longer than standard industrial tablets—ipctech tablets minimize frequent replacement expenses. Their industrial-grade components also feature low failure rates, significantly cutting repair costs.

In outdoor and harsh industrial settings, industrial panel PCs are not just tools—they are the “guarantee of production continuity” and the “engine of operational efficiency.” Selecting a product that fits the scenario and delivers stable reliability helps businesses minimize losses and create greater value.

With 15 years of deep expertise in industrial computing, ipctech consistently prioritizes “stable operation in extreme environments.” Every step—from product development to after-sales support—is centered around “customer needs”:

• R&D: Our 100+ industrial design team subjects every product to over 1,000 hours of environmental simulation testing (extreme temperatures, vibration, water spray) to ensure zero failures in harsh conditions.

• Manufacturing: Achieves a 99.8% product qualification rate.

• After-sales Support: We offer 3-5 year warranties and 24/7 technical support, providing global after-sales service.

If you're seeking reliable industrial tablet solutions for outdoor or harsh industrial environments, choose ipctech. We make industrial panel PC computing more reliable, efficient, and cost-effective in extreme conditions!

Consumer-grade computers are designed for “comfortable indoor environments.” When confronted with extreme temperatures, dust, moisture, vibration, and impact—pressures unique to industrial settings—they often fail miserably. Industrial Panel PCs, however, are computing devices engineered for harsh environments, becoming critical for maintaining production continuity and ensuring operational efficiency. With 15 years of deep expertise in industrial computing, IPCTech has consistently centered its R&D philosophy on “stable operation in extreme conditions.” Its industrial panel PCs not only meet multiple stringent global certifications but also deliver premium automation solutions to clients across petrochemical, mining, construction, and food processing sectors.

Core Requirements for Industrial Tablet PCs in Harsh Environments

1. Environmental Durability Certification

The “ruggedness” of industrial equipment hinges on whether it has passed authoritative certifications—an industry-recognized “hard threshold.” The most prevalent global certification systems include IP protection ratings, NEMA protection standards, and IEC (International Electrotechnical Commission) standards. These define a device's environmental adaptability across three dimensions: “dust and water resistance,” “corrosion and impact resistance,” and “temperature and vibration tolerance.”

• IP Rating: Primarily focuses on “dustproofing” and “waterproofing” capabilities. For outdoor and industrial settings, a minimum IP65 rating (complete dust protection, withstands low-pressure water jets) is required. Environments involving frequent washing (e.g., food processing, car washes) demand IP67 (short-term immersion resistance) or IP69K (high-pressure/high-temperature water jet resistance). All ipctech industrial tablets come standard with IP65 or higher ratings.

IEC Standards: Core evaluation focuses on “temperature and vibration stability.” IEC 60068-2-1 addresses low-temperature environments, IEC 60068-2-2 covers high-temperature conditions, and IEC 60068-2-6 specifies vibration testing. All ipctech products pass critical IEC standards, ensuring long-term reliability in extreme environments.

2. Temperature Resistance

Extreme temperatures are the primary threat in outdoor and industrial settings. Winter outdoor sites in northern regions often drop below -20°C, causing standard computer batteries to drain rapidly and screens to crack from freezing. Meanwhile, workshop temperatures in steel mills and glass factories can exceed 60°C, forcing computer processors to throttle down due to overheating or even burning out motherboards.

The temperature resilience of industrial tablets hinges on two factors: operating temperature range and thermal management system:

• Operating Temperature Range: Premium industrial tablets should cover the standard extreme range of -30°C to 70°C. Specialized scenarios (e.g., Arctic expeditions, desert oil fields) require coverage from -40°C to 75°C. For low-temperature environments, iPCTech developed “Active Heating Technology.” Below -20°C, the device automatically activates internal heating modules to ensure battery and display functionality. For high-temperature scenarios, it employs a “Fully Enclosed Passive Cooling Design.” This utilizes an aluminum alloy casing to rapidly dissipate heat, maintaining low temperatures without fans (avoiding dust clogging).

• Thermal Management Technology: Preventing localized overheating is paramount. Optimized motherboard layout and shell heat dissipation patterns ensure even heat dispersion from core components like processors and hard drives. Even in 70°C environments, surface temperatures remain below 45°C, preventing operator burns.

3. Vibration and Shock Resistance

In scenarios like transport vehicles (trucks, excavators), production line conveyors, and mining machinery, devices endure prolonged high-frequency vibration or sudden impacts. Standard computers use “plug-in connections” for components like hard drives and memory, where vibration causes poor contact. Sudden impacts (device drops, heavy object collisions) can directly damage screens and motherboards.

• MIL-STD Certification: This U.S. military standard for “harsh environment resistance” includes MIL-STD-810H—the most stringent version—covering tests for vibration (50–2000Hz), shock (1000G instantaneous impact), and drops (1.2m onto concrete).

• Structural Design: ipcTech employs a fanless design. Capacitive or resistive touch options are available. It offers strong anti-interference capabilities and high expandability, meeting the demands of harsh industrial environments. The aluminum alloy chassis ensures 24/7 operation in temperatures ranging from -20°C to 60°C.

4. Hardware and Software Reliability

For industrial tablets, internal components matter more than external appearance—hardware must ensure long-term stable operation, while software must be compatible with specialized industrial systems and tools. Otherwise, even a “rugged exterior” cannot meet practical demands.

• Hardware: Industrial-grade “core components”: ipctech employs a hardware combination of “industrial-grade motherboard + wide-temperature storage + stable power supply”:

◦ Motherboard: Features Intel or AMD processors engineered for industrial environments (e.g., Intel Core i5-1135G7, AMD Ryzen 3 5300U), supporting wide-temperature operation (-40°C to 85°C) with fanless design (preventing dust accumulation) for over 10 years of service life.

◦ Storage: Utilizes wide-temperature SSDs (-40°C to 85°C), which withstand higher vibration and shock than standard SSDs while delivering more stable read/write speeds (sequential read/write ≥500MB/s), preventing data loss due to storage failures.

◦ Power Supply: Equipped with a “wide-voltage power module” (input voltage 9–36V DC) to adapt to voltage fluctuations in industrial environments. Features overvoltage, overcurrent, and short-circuit protection to prevent device damage from power issues.

• Software: Compatible with the “Industrial Ecosystem”: IPCTech industrial tablets support mainstream industrial operating systems and software:

◦ Operating Systems: Pre-installed with Windows 10 IoT Enterprise and Linux, ensuring long-term system stability without frequent upgrades.

Software Compatibility: Seamlessly supports SCADA, MES, and IoT monitoring tools, enabling integration with a wide range of industrial equipment.

IPCTECH 2025 Top 5 Industrial Tablet Recommendations

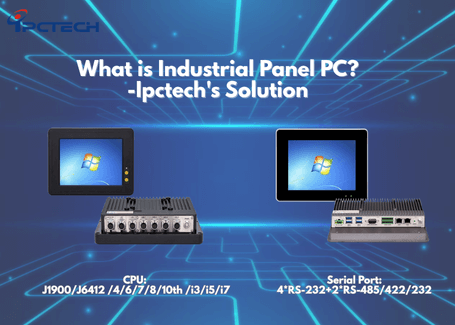

| TYPE | Screen | CPU | I/O interface | System |

| Model: QY-P8070 | 7 inch LED screen, Resolution:800*480 | Intel Celeron and Core N95/N100/ J1900/4/6/7/8/10th-i3/i5/i7 | 2*RJ-45, 4*USB, 6*COM Ports | Windows 7 / 10 / 11 and Linux |

| Model: QY-P8080 | 8 inch LED screen, Resolution:800*600 |

Intel Celeron and Core N95/N100/J1900/4/6/7/8/10th-i3/i5/i7 | 2*RJ-45, 4*USB, 6*COM Ports | Windows 7 / 10 / 11 and Linux |

| Model: QY-P8101 | 10.1 inch LED screen, 1280*800 Resolution |

Intel Celeron and Core N95/N100/4/6/7/8/10th-i3/i5/i7 | 2*RJ-45, 4*USB, 6*COM Ports | Windows 7 / 10 / 11 and Linux |

| Model: QY-P8104 | 10.4 inch LED screen, 1024*768 Resolution |

Intel Celeron and Core N95/N100/J1900/J6412 /4/7/8/10/12th-i3/i5/i7 B365 (6/7/8/9th) H670 (12/13/14th) | 2*RJ-45, 4*USB, 6*COM,1*HDMI,1*Expansion Card | Windows 7 / 10 / 11 and Linux |

| Model: QY-P8121 | 12.1 inch LED screen, 1024*768 Resolution |

Intel Celeron and Core N95/N100/J1900/J6412 /4/7/8/10/12th-i3/i5/i7 B365 (6/7/8/9th) H670 (12/13/14th) | 2*RJ-45, 4*USB, 6*COM,1*HDMI,1*Expansion Card | Windows 7 / 10 / 11 and Linux |

How to Select the Right Industrial Panel PCs for Your Application?

Step 1: Map Environmental Stressors and Define Core Requirements

• Question 1: What environmental threats will the device face?

List specific environmental factors:

Temperature range (e.g., “Winter -15°C to Summer 45°C,” " Constant workshop temperature 60℃“), humidity/moisture conditions (e.g., ”Daily high-pressure washing,“ ”High-salt marine environment“), dust concentration (e.g., ”Heavy dust in mining,“ ”Light dust in standard workshops“), vibration/impact intensity (e.g., ”Fixed installation,“ ”Mobile vehicle use,“ ”Mining machinery vibration").

•Question 2: What core functions must the device perform?

Define usage scenarios: Is it for real-time monitoring of multiple devices (requiring large-size, high-resolution screen), “mobile operation logging” (requiring long battery life, lightweight design), “basic data entry” (requiring low cost, easy operation), or “stable operation under extreme temperatures”

•Question 3: What installation and usage constraints exist?

Consider physical space, power supply, network environment, etc.

Step 2: Focus on Core Parameters

•Must-Check Parameter 1: Protection Rating

Outdoor/humid environments: IP66 or higher;

Dusty environments: IP65 or higher;

•Must-Check Parameter 2: Operating Temperature Range

Standard outdoor/industrial environments: -20°C to 60°C;

Extreme low/high-temperature environments: -30°C to 70°C, -40°C to 75°C.

• Essential Parameter 3: Hardware Stability

Prioritize “industrial-grade components”: e.g., Intel/AMD industrial-grade processors, wide-temperature SSDs, fanless design (to prevent dust clogging).

What Value Can Investing in High-Quality Rugged Industrial Tablets Bring to Enterprises?

1. Reduce Downtime and Ensure Production Continuity

In industrial settings, “time is money” rings especially true. Equipment failures causing downtime not only result in lost production value but can also trigger chain reactions (such as order delays and customer attrition).

2. Boost operational efficiency and reduce labor costs

The “intelligence” and “compatibility” of industrial tablets significantly streamline manual operations and enhance efficiency:

• Real-time data collection: By integrating with SCADA/MES systems, ipctech tablets capture equipment performance metrics (e.g., temperature, RPM, output) in real time, eliminating manual logging.

• Remote monitoring and control: Supported by 5G/Wi-Fi networks, ipctech tablets enable remote equipment status monitoring and parameter adjustments.

• User-friendly operation: Wide-screen displays, glove-compatible touchscreens, and anti-glare designs simplify employee tasks.\

3. Reduce total cost of ownership for long-term savings

While high-quality industrial tablets have higher upfront costs, they prove more economical over the entire “procurement-use-disposal” lifecycle:

• Reduced maintenance and replacement costs: With a 5-10 year lifespan—2-3 times longer than standard industrial tablets—ipctech tablets minimize frequent replacement expenses. Their industrial-grade components also feature low failure rates, significantly cutting repair costs.

Choose IPCTECH for more reliable industrial panel PC computing in extreme environments

In outdoor and harsh industrial settings, industrial panel PCs are not just tools—they are the “guarantee of production continuity” and the “engine of operational efficiency.” Selecting a product that fits the scenario and delivers stable reliability helps businesses minimize losses and create greater value.

With 15 years of deep expertise in industrial computing, ipctech consistently prioritizes “stable operation in extreme environments.” Every step—from product development to after-sales support—is centered around “customer needs”:

• R&D: Our 100+ industrial design team subjects every product to over 1,000 hours of environmental simulation testing (extreme temperatures, vibration, water spray) to ensure zero failures in harsh conditions.

• Manufacturing: Achieves a 99.8% product qualification rate.

• After-sales Support: We offer 3-5 year warranties and 24/7 technical support, providing global after-sales service.

If you're seeking reliable industrial tablet solutions for outdoor or harsh industrial environments, choose ipctech. We make industrial panel PC computing more reliable, efficient, and cost-effective in extreme conditions!

Recommended