High-performance Fanless Box PC for Industrial Automation

2025-06-23

Background

As industrial automation develops towards intelligence and refinement, the demand for computing terminals in production facilities is becoming increasingly stringent. Compact space, powerful performance, and adaptable to complex environments have become the industry's most pressing needs. High-performance fanless mini-PCs, with their unique design and excellent performance, break the size and function limitations of traditional PCs, and are gradually becoming an innovative force in the field of industrial automation, providing a brand new solution for the upgrading of the manufacturing industry.

What is Fanless Box PC?

The high-performance fanless mini PC is an industrial-grade computer device that combines high-performance computing power with an ultra-compact body and adopts a fanless cooling design. Compared with traditional industrial PCs, its size is greatly reduced, and some products are only a fraction of the size of conventional industrial PCs, but they can integrate hardware configurations comparable to or even better than those of mainstream industrial PCs. In terms of hardware architecture, these mini-PCs are usually equipped with high-performance, low-power processors to ensure powerful computing performance while effectively controlling power consumption and heat generation. At the same time, equipped with high-capacity high-speed memory and solid-state hard disk, to meet the needs of industrial automation in real-time data processing, multi-task parallel operation. In terms of interfaces, it integrates a wealth of industrial-grade interfaces, including RS-232/485 serial ports, bus interfaces, Ethernet interfaces, USB interfaces, etc., in order to adapt to all kinds of industrial sensors, actuators and communication devices.

The fanless design of high-performance fanless mini PC is the core technical highlight. Traditional computers rely on fans to dissipate heat, and the mechanical movement of fans not only generates noise, but also has problems such as short service life and easy to accumulate dust and damage. Fanless mini PCs, however, have a complete passive cooling system through an integrated metal casing, highly efficient heat-conducting materials, and well-designed cooling fins. The heat generating components inside the device and the metal casing are filled with highly thermally conductive silicone or connected with heat conduits to quickly conduct heat to the casing, and then the fins on the surface of the casing are used to conduct natural convection with the air, realizing highly efficient heat dissipation in a fanless state and eliminating the hidden dangers caused by fan failures from the root.

Why Choose Fanless Mini PC?

Extremely Compact, Flexible Deployment

The miniaturized design of the high-performance fanless mini PC gives it a significant advantage in space utilization. In industrial production, especially in the fields of precision manufacturing and electronic assembly, the layout of production equipment is compact, leaving very limited space for computing devices. The compact size of the mini PC can be easily installed inside the equipment cabinet, at the joints of the robotic arm, behind the control panel and other small spaces, and can even be embedded in a way that integrates with the industrial equipment. This flexible deployment not only saves valuable industrial space, but also reduces wiring complexity, improves equipment integration, and provides more possibilities for production line optimization and upgrading.

Stable and Durable, Fearless of Harsh Environments

Industrial environments are often full of challenges, with factors such as high temperature, low temperature, high humidity, dust, and vibration testing the reliability of equipment. High-performance fanless mini PCs are designed with a fully enclosed metal casing for excellent protection. With protection ratings of IP65 and above, it can completely block dust intrusion and withstand water splashes and short-term immersion. In terms of internal structure, it is able to withstand vibration shock of up to 5G and shock acceleration of up to 10G through the design of reinforced circuit boards and anti-vibration reinforcement of components. Whether it's a high-temperature metallurgical workshop, a high-humidity food processing environment, or a mining site with frequent vibrations, the fanless mini PC can run stably and ensure the continuity of industrial production.

Quiet and Low Consumption, Green and Energy Saving

Another major advantage of the fanless design is the near-zero noise operation experience. In noise-sensitive industrial scenarios, such as medical equipment production workshops and semiconductor cleanrooms, the noise of traditional industrial computer fans may interfere with the normal operation of precision instruments and affect product quality. High-performance fanless mini PCs run without mechanical noise, creating a quiet and comfortable working environment for staff and avoiding the potential impact of noise on precision production processes. In addition, these devices use low-power hardware and energy-saving design, compared with the same performance of the traditional industrial computer, energy consumption can be reduced by 30% - 50%, which helps enterprises to reduce operating costs and practice the concept of green industrial development.

Powerful Performance for Intelligent Computing

Despite its compact size, the high-performance fanless mini PC has the computing power of a large industrial computer. Its high-performance processor with high-capacity memory and high-speed storage can quickly handle all kinds of complex tasks in industrial automation. In terms of real-time data acquisition, it can simultaneously access multiple sensors and process tens of thousands of data per second; in terms of algorithm operation, it can efficiently run industrial control algorithms, machine learning algorithms, etc. to achieve intelligent control and optimization of equipment; in the field of visual processing, it supports high-definition video decoding and AI image recognition to meet the needs of industrial visual inspection, robot visual guidance and other applications. Whether it's simple logic control or complex intelligent decision-making, fanless mini PCs can handle it with ease!

Fanless Box PC for Industrial Automation

Flexible Intelligent Production Line

In industrial automation, flexible production lines need to quickly adjust equipment parameters and processes according to different production tasks. As the control core of the production line, the high-performance fanless mini PC connects all kinds of production equipments and sensors, collects real-time data on equipment operation status and production progress, and dynamically adjusts the production rhythm and optimizes the cooperative operation of the equipments by means of the built-in control algorithms and scheduling system. When the production task changes, the mini PC can quickly complete the program switching and parameter configuration to realize the rapid transfer of the production line, effectively improve the production efficiency and flexibility to meet the market demand for personalized and customized products.

Full-process quality control

Quality control is a key aspect of industrial production. High-performance fanless mini PC plays an important role in the whole process quality control. Combined with industrial vision inspection system, it utilizes its powerful image data processing capability to conduct real-time inspection of products in the production process. By analyzing product appearance, size, defects and other information through AI algorithms, it can quickly and accurately identify unqualified products and issue timely alarms or control equipment for automatic sorting. At the same time, the mini-PC can also upload the inspection data to the quality management system, providing data support for process optimization and quality traceability, and realizing the whole process of quality control from raw material inspection to finished product shipment.

Industrial Internet of Things Integration

With the development of Industrial Internet of Things (IIoT), equipment interconnection and data sharing have become an important trend in industrial automation. High-performance fanless mini PCs are deployed as edge computing nodes for IIoT at production sites, taking on the tasks of data acquisition, pre-processing and edge computing. It connects production equipment, sensors, meters and other terminal devices through a variety of industrial communication protocols to collect real-time information such as equipment operation data and environmental parameters. It filters, analyzes and processes the data on the edge side and uploads the key data to the cloud to reduce the data transmission pressure and delay; at the same time, it receives the commands issued by the cloud to realize the real-time control of local equipment. This edge computing model improves the real-time and security of data processing and enhances the reliability and responsiveness of the industrial IoT system.

Digital Twin Drive

Digital twin technology realizes real-time monitoring, simulation optimization and predictive maintenance of the production process by constructing a virtual model of the physical entity. The high-performance fanless mini PC provides powerful computing support for the digital twin system. It is able to collect real-time operating data of physical equipment and synchronize the data to the virtual model, so that the virtual model and the physical entity maintain a high degree of consistency. At the same time, it utilizes its graphic processing and computing power to render and simulate the virtual model, simulate the operating status of the equipment under different working conditions, and predict potential failures and performance bottlenecks. Engineers can operate the mini-PC to optimize processes and adjust parameters in the virtual environment, and apply the optimized solutions to actual production, reducing trial-and-error costs and improving production efficiency and product quality.

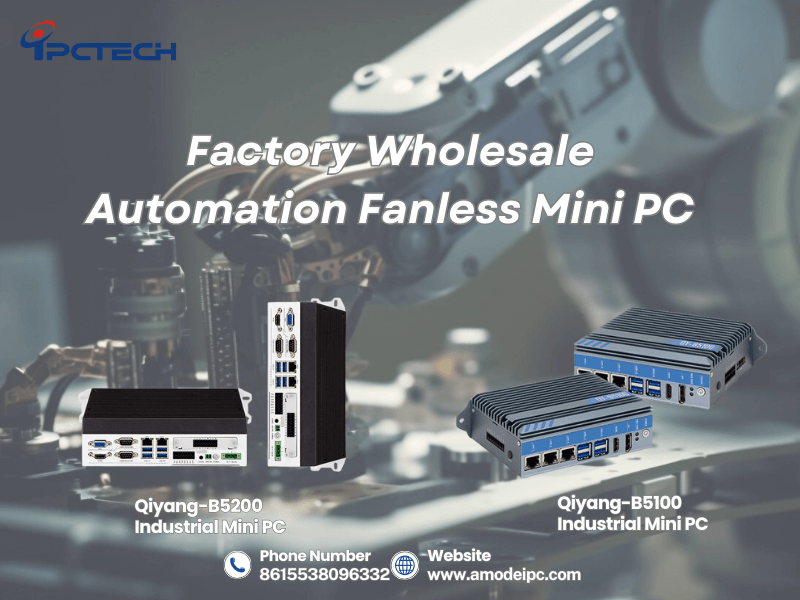

IPCTECH Solutions

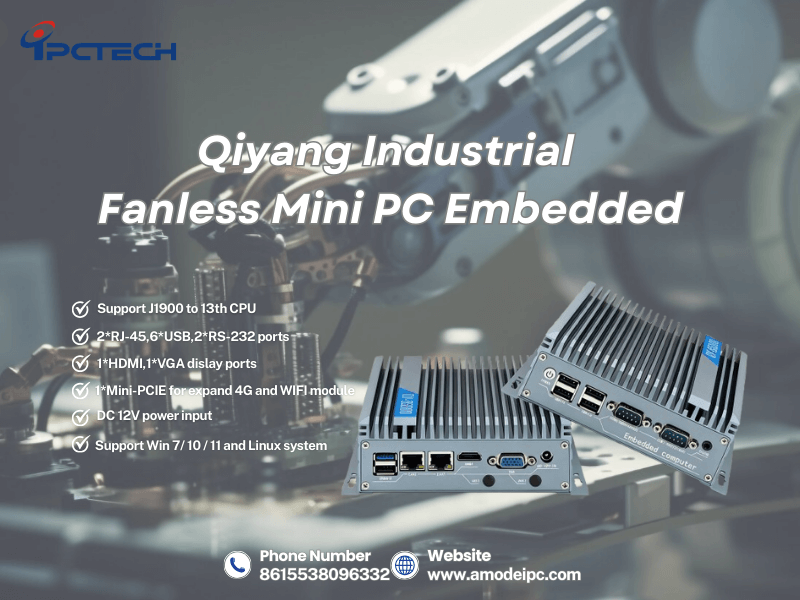

Qiyang B5300 Industrial mini pc for sale

1. Support J1900 to 13th CPU

2. 2*RJ-45,6*USB,2*RS-232 ports

3. 1*HDMI,1*VGA dislay ports

4. 1*Mini-PCIE for expand 4G and WIFI module

5. DC 12V power input

6. Support Win 7/ 10 / 11 and Linux system

How to choose the right Industrial fanless box pc?

Matching Performance Parameters to Actual Needs

When choosing a high-performance fanless mini PC, the first thing to do is to determine the hardware configuration according to the computing needs of specific application scenarios. Processor, for general data acquisition and logic control tasks, you can choose entry-level processors; if it involves complex algorithms, AI image processing and other tasks, you need to carry a high-performance processor. Memory capacity should be selected according to the number of programs running at the same time and the amount of data processing, usually 8GB memory can meet the basic applications, for large data processing, multi-task parallel operation scenarios, it is recommended to configure 16GB or higher capacity memory. Storage devices are preferred to solid state drives (SSD), which have fast reading and writing speeds, good shock resistance, and capacities ranging from 256GB - 2TB according to data storage requirements.

Interface Adaptation Ensures Device Interconnection

Industrial automation equipment is diverse, with different interface requirements. High-performance fanless mini PCs must have rich and adaptable interface types and numbers. When choosing, according to the actual needs of the connected devices, ensure that the PC has enough RS-232 serial ports and bus interfaces to connect industrial sensors, controllers and other devices; at the same time, configure multiple Ethernet interfaces, USB interfaces, to meet the needs of network communication and external device expansion. In addition, we should also pay attention to the communication protocols supported by the interface to ensure compatibility with existing industrial systems.

More Mini PC Options for your Choice

Conclusion

High-performance fanless mini PC has become an indispensable core device in the field of industrial automation by virtue of its compact size, excellent performance, stable operation capability, and wide range of application adaptability. It plays an important role in flexible production line control, quality control, industrial Internet of Things integration, digital twins and other key aspects, promoting industrial production to intelligent, efficient and green direction. For industrial enterprises, the efficient and reasonable application of performance fanless mini PC is an important way to improve production efficiency, reduce operating costs and enhance market competitiveness. With continuous technological innovation and market development, high-performance fanless mini PCs will play a greater role in industrial automation and provide solid technical support for the high-quality development of the manufacturing industry.

Recommended