Where are industrial PCs used

2025-06-09

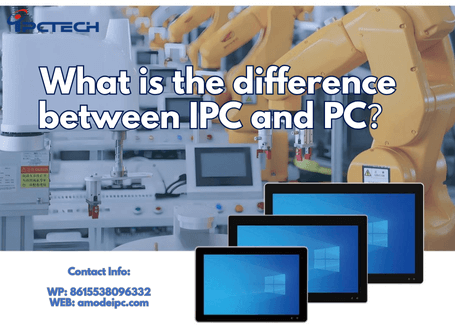

What is an industrial panel pc?

Industrial PCs, are specialized computers designed for industrial environments, whose core mission is to operate stably under harsh conditions that ordinary computers are not capable of. These devices are dust-proof, shock-resistant, high and low temperature (-40°C to 85°C), and EMI-resistant, and are configured with long-life-cycle hardware components (typically supporting 3-5 years of continuous supply) and customized I/O interfaces to suit industrial automation needs. From automotive production lines to oil rigs, from smart grids to medical operating rooms, industrial PCs are becoming the core infrastructure for digital transformation in a variety of industries with high reliability and flexibility.

Application of Industrial Panel PC

Manufacturing

Automated Production Line Control

In the automation upgrade of the manufacturing industry, the industrial computer plays the role of “nerve center”. Through real-time data acquisition and processing, it can accurately control robotic arm gripping, conveyor belt speed regulation and other actions to ensure that the components are seamless. At the same time, the SCADA integrated with the industrial computer can monitor the operation status of the equipment in real time, reducing the failure rate of the equipment, and helping to improve production efficiency and stability.

Machine Vision and Quality Inspection

The popularization of machine vision technology can not be separated from the powerful computing power of industrial computers. In the food packaging industry, the high-speed vision inspection system driven by industrial computers can complete the inspection of product appearance defects, weight deviation and seal integrity within 0.5 seconds, which is more than 20 times more efficient than manual labor, and effectively protects the quality and safety of food.

Predictive maintenance and asset tracking

The application of industrial computers in the field of predictive maintenance is changing the traditional mode of equipment maintenance. Sensors collect real-time data on equipment vibration and temperature, and built-in algorithms predict the risk of failure, providing early warning of equipment maintenance needs and avoiding production interruptions and cost losses due to unexpected failures.

Energy and Utilities

Smart Grid and Renewable Energy

Industrial computers play a key role in the smart grid and renewable energy sectors. In wind farms, industrial computers deployed in tower control cabinets can adjust the pitch angle of wind turbines in real time to optimize the efficiency of wind energy capture, and at the same time process sensor data through edge computing to reduce cloud transmission delays and improve system response speed. In substations, ruggedized industrial PCs are used as SCADA hosts and support dual-machine hot standby, which can maintain at least 4 hours of critical data recording even in the event of a power outage, ensuring the safe and stable operation of the power system.

Oil and Gas Extraction

The challenging environment of oil and gas extraction makes explosion-proof industrial PCs a standard in this field. On drilling platforms, these computers can stably run mud parameter monitoring, well control system control and other tasks in hazardous environments such as excessive hydrogen sulfide concentration and high salt spray, ensuring the safety and continuity of mining operations. The embedded industrial computer carried by the pipeline inspection robot generates three-dimensional maps in real time by means of LIDAR and camera, and detects pipeline leaks with millimeter-level accuracy, which significantly improves the efficiency and accuracy of pipeline operation and maintenance.

Transportation

Intelligent Transportation System

The efficient operation of intelligent transportation systems relies on the powerful processing capability of industrial computers. The industrial computer built into the traffic signal controller at intersections can dynamically adjust the length of traffic lights in combination with real-time traffic flow data. The wide-temperature industrial computer used in the ETC gantry of highways can work stably in -30°C winter or 45°C summer, and it can process more than 10,000 vehicle identification transactions per second, ensuring smooth and efficient highway traffic.

Rail transportation and aviation

In the field of rail transportation, high-speed rail on-board industrial computers are responsible for key functions such as traction converter control and axle temperature monitoring, etc. Their design complies with the standards of rail transportation electronic equipment, and they can maintain stability in complex operating environments. In the field of aviation, the industrial computer in the airport baggage sorting system drives the high-speed sorter, which can handle 20,000 pieces of baggage per hour to ensure the accuracy of sorting, and significantly improve the efficiency and accuracy of baggage handling in the airport.

Healthcare

Medical Device Integration

Industrial computers play an important role in medical device integration. As the image reconstruction engine of MRI and CT scanners, it needs to complete massive data computation within seconds to ensure the accuracy and reliability of medical images. In the operating room, industrial tablet PCs are used as control terminals for anesthesia machines and support glove-operated touch screens, which reduces the risk of cross-infection among healthcare workers during surgery and improves the safety and ease of operation in the operating room.

Smart Pharmacy and Logistics

The automated dispenser of the smart pharmacy realizes drug inventory management, prescription audit and accurate capture through industrial computers. In medical cold chain transportation, the on-board industrial computer monitors the temperature and humidity of the refrigerator box in real time and automatically triggers an alarm and adjusts the refrigeration parameters when it exceeds the standard, so as to ensure the quality and safety of vaccines, blood and other biologics products in the transportation process.

Features of Industrial panel pc manufacturer

Extreme Durability

The physical protection of industrial PCs is the industry standard. The sealed IP65-rated chassis resists dust and liquid intrusion, and maintains stable operation even in the dusty environments of a food processing plant or the high humidity corridors of a mine. Another highlight is the anti-vibration and anti-shock design. The fanless structure or reinforced chassis can withstand high-frequency vibration of production line equipment as well as severe bumps during transportation, avoiding data loss or system crash due to loose hardware. In terms of temperature resilience, standard models can operate from -20°C to 60°C, and special customized models can even operate in extremely cold warehouses at -40°C or smelter temperatures of 85°C.

Long Life Cycles and Scalability

Unlike commercial PC components, which have an average iteration cycle of 1-2 years, key components of industrial computers, such as motherboards and processors, can be supplied on a 5-7 year cycle, which means that enterprises can maintain stable long-term operation of the system without having to replace the hardware frequently, thus significantly reducing the cost of equipment replacement. In terms of scalability, industrial computers support PCI/PCIe expansion cards, which can flexibly access PLCs, machine vision cards, motion control cards and other industrial peripherals to meet the functionality of different scenarios to meet the demand for expansion, such as seamlessly integrating robotics control modules or real-time data acquisition equipment in the automated production line.

How to choose the right industrial PC?

When choosing an industrial PC, environmental suitability is the first and foremost consideration. According to the dust, humidity and vibration level of the actual application scenarios, you need to choose the model with the appropriate level of protection. In terms of performance matching, you need to choose the hardware configuration according to the specific needs of the task: machine vision applications require high-computing power GPUs, data acquisition scenarios require multi-channel ADC modules, and edge computing scenarios require models that support AI-accelerated chips. In addition, the service system is also crucial. ipctech provides more than 5-year warranty, continuous firmware update and customized OEM service to ensure the long-term stable operation of the equipment and meet the personalized needs.

Advantages of Industrial Panel PCs from OEM-IPCtech

As industrial automation and intelligence continue to advance, more and more industries are beginning to pay attention to the application of industrial three-proof tablet PCs. However, general-purpose products often fail to meet each industry's specific needs. OEM manufacturers provide customized solutions that meet customers' requirements for performance, appearance, functionality, and other aspects by understanding their specific needs.

Demand for Industrial Panel PC OEM

Customization of industrial panels is based on customer demand for computers in application scenarios. According to user needs, it can be customized for multifaceted performance design. Unlike ordinary business computers, customized triple-proof industrial panel PC OEMs are characterized by diverse industrial environments, installation methods, and external devices. This requires them to be versatile in order to meet users' needs.

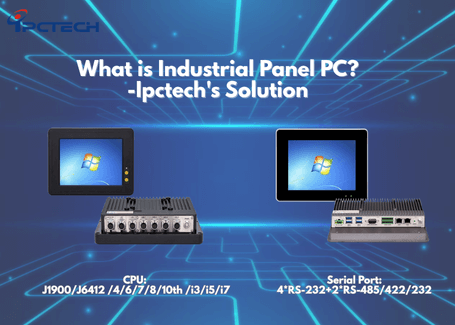

High efficiency, stability, and rich interfaces

The industrial panel PC OEM has a compact overall structure and a scientific, professional heat dissipation design. It focuses on CPU technology, enabling users to experience better computing and imaging performance with lower power consumption. A rich expansion function is also an essential requirement when choosing an industrial panel PC OEM. A variety of mini PC standard expansion card options are available to meet different application needs. This flexible design allows users to expand the fieldbus card to enable communication between devices.

Ensuring Product Reliability

The industrial panel PC OEM consists of a host screen that constitutes an all-in-one machine. The advantage of this design is the stability of its performance. OEM services strictly implement quality control standards throughout the production process. From purchasing raw materials to processing and inspecting finished products, each step is subject to rigorous control. This rigorous quality control system ensures that the industrial panel PC OEM can operate stably in harsh industrial environments, providing enterprises with stable and reliable revenue.

Providing Flexible Solutions

In today's increasingly competitive market, enterprises must be able to respond quickly to market changes and seize business opportunities. Industrial Panel PC OEM provides flexible solutions for businesses with its ability to rapidly adjust product design and production plans according to market demand.

Even if the standardized tablet PC has a good modular design and performance, user needs are constantly changing and growing. Sometimes, standardized products still cannot meet users' needs. In these cases, professional manufacturers and services are necessary to alleviate customers' problems. IPCtech has professional technical capabilities and R&D advantages. We provide customers with advanced and innovative technologies, competitive solutions, and products. We quickly turn customers' ideas into feasible solutions.

Industrial Panel PC-IPCtech

From traditional manufacturing to intelligent manufacturing, from single device control to complex system synergy, industrial computers have become the core driving force for upgrading in various industries with their irreplaceable reliability and flexibility. Whether in a molten steel mill or an oil and gas platform in a ten-thousand-meter deep sea, industrial PCs have always been quietly supporting the operation of modern industry. ipctech, as a manufacturer with more than 15 years of sales of panel PCs, has established profound cooperation with many industrial automation agents, system integrators, equipment manufacturers, CNC machine tool manufacturers, welcome to visit our factory!

Recommended