Features of Industrial Panel PC

2025-04-24

INTRODUCTION

In today's rapidly changing industrial world, precision, efficiency and reliability have become core elements of business operations. Industrial tablets are playing an increasingly critical role as the “heroes behind the scenes” of automation and control. From production lines in manufacturing to critical operations in healthcare organizations and the energy industry, these rugged computing devices are revolutionizing the way businesses operate.

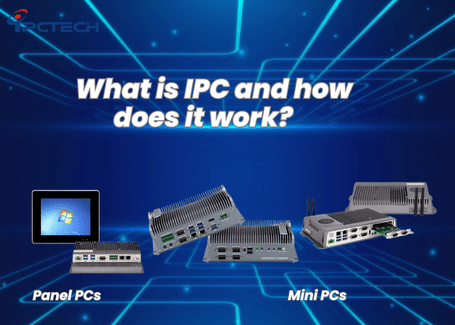

What is an Industrial Tablet PC?

An industrial tablet is a device that combines a computer system with a flat panel display, usually equipped with a touchscreen interface. Unlike ordinary PCs, it is designed to cope with harsh industrial environments and can withstand extreme temperatures, dust, moisture, vibration and shock.

Its enclosure is built with durable materials such as stainless steel or aluminum, and meets strict industry protection standards (IP) and military-grade durability standards (MIL-STD). This rugged construction ensures long-term stable operation of the equipment under harsh conditions, providing reliable protection for industrial production.

As the core control hub of an industrial automation system, the Industrial Panel PC enables operators to monitor, control and manage complex processes in real time. Equipped with a powerful processor, ample memory and advanced connectivity options, it can handle high-duty applications and integrate seamlessly with other industrial equipment.

Key Features of Industrial Panel PCs for Automation and Control

Ruggedized Construction

Industrial Panel PCs meet or exceed military-grade standards for shock, vibration and temperature resistance, enabling stable operation even in the most extreme environments.

High protection ratings such as IP65 or IP69K ensure that the devices are resistant to dust, water and other contaminants, making them ideal for use in harsh environments such as food processing plants and washdown areas.

The units can operate over a temperature range of -20°C to 60°C and beyond, whether in cold storage facilities or hot industrial plants.

Touch Screen Display

Intuitive touchscreen interfaces provide a user-friendly experience that allows operators to perform complex tasks without extensive training.

Many industrial tablet PCs support multi-touch technology, which further enhances work efficiency and control precision through gesture operations such as pinch-to-zoom and swipe.

For outdoor scenarios, the high-brightness displays offer excellent sunlight visibility and can display content clearly even in direct sunlight.

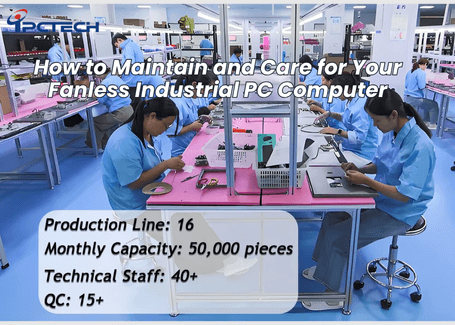

Fanless Design

The fanless design avoids the use of moving parts and reduces the risk of mechanical failure, significantly improving the reliability and durability of the device.

Since no fan is required, equipment maintenance needs are dramatically reduced, eliminating the need for regular filter cleaning or fan replacement, reducing downtime and maintenance costs.

Fanless operation enables silent operation, making it particularly suitable for noise-sensitive environments such as healthcare facilities and laboratories.

Expandability

The modular architecture design allows users to easily add components such as memory, storage and I/O modules to expand system functionality as needed.

This flexible design provides users with the possibility to customize their system to meet current needs and easily expand as their business grows.

Choosing an industrial panel PC with scalability helps protect investments and ensures that the system can adapt to new technologies and applications.

Connectivity Options

Industrial panels offer a wide range of wired connectivity options, including Ethernet, USB, serial, and CAN bus, for a stable connection to a variety of industrial devices and systems.

It also supports wireless connections such as Wi-Fi and Bluetooth, making it easy to integrate with wireless devices and networks for more flexible deployment.

To ensure compatibility with industrial automation systems, the device supports a variety of industrial Ethernet protocols.

Installation Flexibility

Most industrial panel PCs are VESA-compliant, allowing them to be easily mounted on walls, panels, or other surfaces using VESA brackets.

For scenarios that require flush mounting, the devices offer panel mounting options for a clean, integrated look.

In environments such as server rooms where space is limited, rack mounting kits are available for mounting industrial panels in standard 19-inch racks.

Common Applications for Industrial Tablet PCs

Manufacturing

Used to monitor and control production lines, displaying production data in real time, adjusting machine settings, and triggering alarms in the event of errors or malfunctions to ensure efficient production operation and quality control.

Can perform quality assurance tasks such as product defect detection and dimensional measurement to enhance product quality.

Integrates with inventory management systems for inventory level tracking, order management and supply chain optimization.

Healthcare

Used in healthcare facilities to monitor patient vital signs such as heart rate, blood pressure, and blood oxygen, display patient information, manage medication administration, and support communication between healthcare professionals.

It can be used to display and analyze medical images such as X-ray, CT, and MRI, and to store and manage patient medical records.

In surgical navigation systems, it provides real-time guidance to surgeons, improves surgical precision, and reduces the risk of complications.

Energy

Used to monitor and control power plants to ensure efficient operation of power generation equipment and stability of the power grid, and to realize control of generators, turbines and other equipment as well as power distribution management.

Monitor and manage energy generation, storage, and distribution in renewable energy systems such as solar and wind farms.

Reduce costs and improve sustainability by monitoring energy consumption, identifying energy saving opportunities, and implementing energy management strategies.

Transportation

In the transportation industry, it is used to manage fleets of trucks, buses, trains, etc., to enable vehicle location tracking, driver behavior monitoring, maintenance schedule management and route optimization.

In traffic management systems, to monitor traffic flow, control traffic signals, and manage parking facilities.

In passenger transportation information systems to provide passengers with real-time train schedules, bus routes, flight status and other information.

Retail

As a point-of-sale (POS) system in retail stores, it supports customers to complete shopping, payment processing, and inventory management, and at the same time, it can display product information, promotions, and advertisements.

Applied to self-service terminals such as automated teller machines (ATMs), ticket vending machines, and self-checkout systems to provide customers with a convenient and efficient transaction experience.

Integrate with inventory management systems for inventory level tracking, order management and supply chain optimization.

Factors to Consider When Buying an Industrial Panel PC

Brightness

The brightness of the screen should be chosen according to the environment in which it will be used. Outdoor applications require a bright display to combat sun glare, while indoor applications do not require high brightness to avoid visual discomfort.

The viewing angle of the display is also important, especially in scenarios where multiple people need to view the screen from different angles, a wide viewing angle ensures clear visibility.

Some industrial tablets are available with anti-glare coatings to minimize reflections and improve visibility in bright environments.

Size

The right size needs to be selected based on the available space and the needs of the application. For applications that require detailed visual information, a larger screen is more appropriate, while smaller devices are suitable for scenarios where space is limited.

If the equipment needs to be moved or transported frequently, preference should be given to compact and lightweight models.

At the same time, it is also necessary to consider the installation method of the equipment, different installation methods have different size requirements.

Installation

Choose the appropriate type of mounting for your application. Common types include VESA mounting, front-loading bezel, and server rack mounting.

The choice of mounting location affects the accessibility and ease of use of the equipment and should ensure ease of operation and maintenance.

Mounting hardware is often supplied with the equipment or purchased separately, so make sure it matches the type and location of the mounting.

Industrial Tablet PC Frequently Asked Questions

What are the uses of Industrial Tablet PCs?

Industrial Panel PCs are mainly used for data acquisition and process control in industrial environments, covering tasks such as production line monitoring, inventory management, vehicle tracking and other tasks that require real-time data processing and control.

What are the protection standards?

Industrial Panel PCs comply with industry protection (IP) standards and military-grade durability (MIL-STD) standards, with IP ratings reflecting the ability of the device to protect against dust, water, etc., and MIL-STD ratings reflecting the ability of the device to withstand environmental stresses such as shock and vibration.

What types of mounting are available?

Common mounting types include VESA mounting, front-loading bezel, and server rack mounting, depending on application requirements and available space.

What type of touchscreen is best suited for an Industrial Panel PC?

The choice of touchscreen technology depends on the environment and application scenario. Surface capacitive touchscreens are commonly found in consumer electronics and require direct skin contact; resistive touchscreens are pressure-sensitive, support gloved hands, and are favored for their durability in industrial environments.

Conclusion

Industrial tablets have become indispensable computing devices for modern industrial applications due to their rugged construction, intuitive touchscreens, fanless design, robust scalability, extensive connectivity options, and flexible mounting options. These features make them instrumental in enhancing productivity, optimizing processes and driving innovation.

If you're looking for a reliable and durable computing solution for industrial operations, industrial tablets are worth considering. Their advanced features and functionality can help organizations increase efficiency, reduce costs, and stay ahead of the curve in a competitive market.

As technology continues to advance, industrial tablets will become more powerful and feature-rich. Whether you're a small business or a large corporation, investing in industrial tablets will be a smart choice to help achieve your business goals and move towards a successful future.

Recommended