What are the advantages of industrial computers over home computers?

2025-11-17

The core objectives of industrial computers are stability, reliability, and long lifespan, ensuring uninterrupted operation in extreme environments or during continuous use.

The key difference between industrial and consumer computers lies in their design goals, application environments, and performance focuses: industrial computers are designed for harsh industrial environments, emphasizing high reliability, stability, and long-term durability; while consumer computers are geared towards everyday general-purpose scenarios, focusing on cost-effectiveness, ease of use, and stylish appearance.

Typical scenarios include: factory automation, intelligent transportation, medical equipment, and outdoor monitoring, where tolerance for failure is extremely low (e.g., production line downtime can cause significant losses).

Reliability and Stability: Industrial computers utilize industrial-grade hardware components (such as wide-temperature processors and ECC memory), ensuring long-term stable operation and an extremely low failure rate through fanless design, reinforced casing, and dust and water-resistant structures (such as IP65 protection rating). Home computer hardware prioritizes consumer-grade cost-effectiveness and is more prone to failure under continuous high loads or harsh environments.

Industrial computer processors (CPUs) use low-power, highly stable industrial-grade chips (such as Intel Atom, Rockchip RK3568, and AMD G-Series).

They support wide-temperature operation (-40℃ to 85℃) and pass aging tests to ensure a 10-year lifespan. Industrial-grade DDR4 memory supports ECC error correction, automatically repairing data errors and preventing system crashes. SLC solid-state drives withstand over 100,000 write cycles, providing data retention for over 10 years.

Home computers, on the other hand, prioritize cost-effectiveness and versatility.

Hardware Design and Expandability

Core Components: Industrial PCs use rigorously selected durable components (such as industrial-grade SSDs) and support a wide operating temperature range of -20℃ to 60℃; consumer PCs mostly use consumer-grade hardware with a narrower operating temperature range.

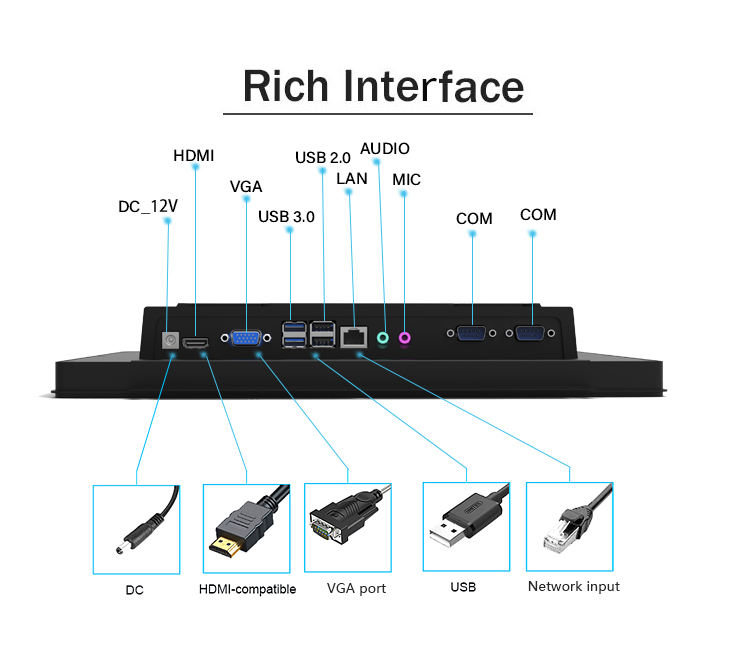

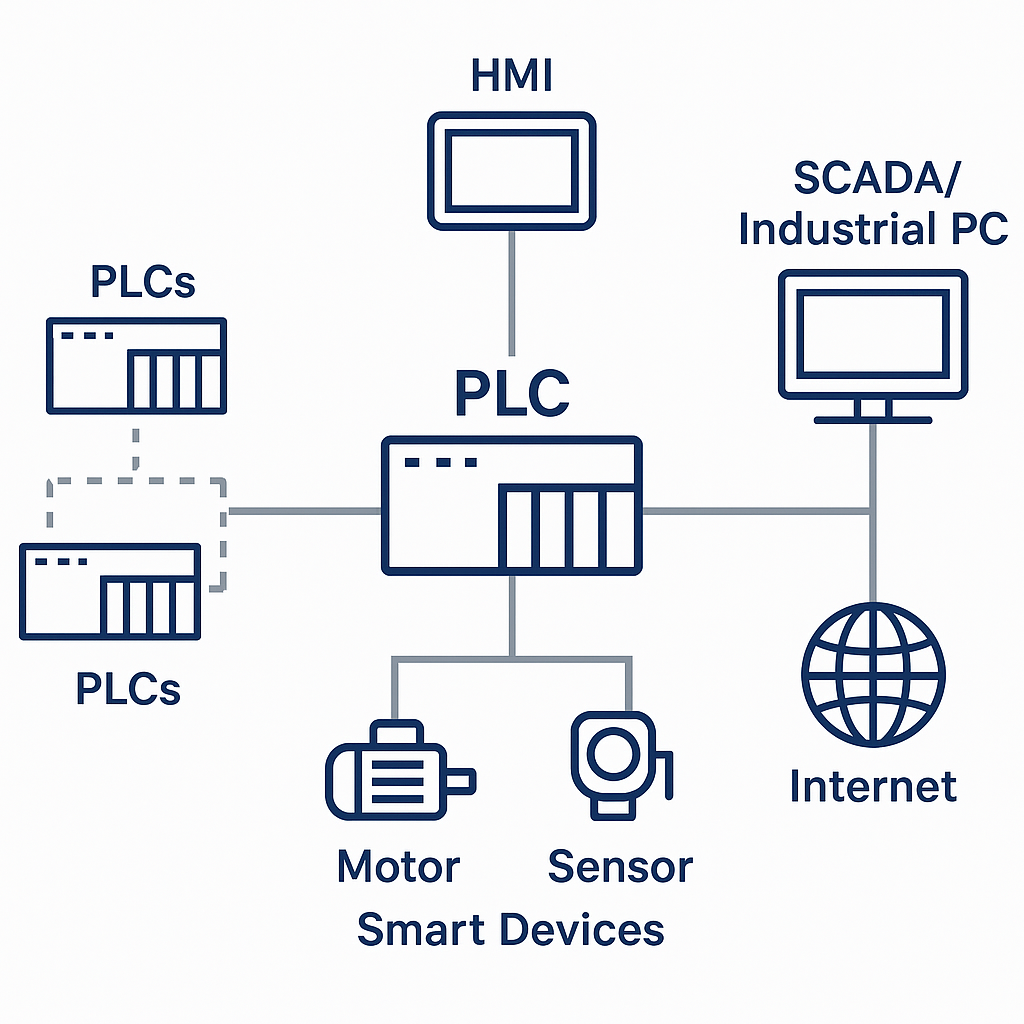

Interfaces and Expansion: Industrial PCs are equipped with industrial interfaces such as RS-485 and CAN bus for easy connection to sensors, PLCs, and other devices; consumer PCs primarily use universal interfaces such as USB and HDMI.

Industrial field requirements are diverse, including the need to connect PLCs, sensors, barcode scanners, cameras, instruments, etc. In such cases, ordinary PCs often face a shortage of interfaces.

Industrial PCs not only come standard with multiple serial ports (COM), multiple USB ports, and multiple LAN ports, but some models also support CAN bus, fiber optic network ports, and PCIe slots.

Thermal Design: Industrial computers often employ passive cooling or industrial-grade fans to prevent dust accumulation; industrial PCs typically use fanless, passive cooling designs with a compact, vibration-resistant internal layout. This structure not only reduces the failure rate but also allows for flexible integration into various mechanical equipment or power distribution cabinets.

Home computers rely on active cooling, making their fans prone to damage.

Ordinary computers have rapid product updates and short component supply cycles, posing a potential risk for long-term projects or large-scale equipment deployments. Industrial PCs, however, emphasize long-term supply, stable compatibility, and after-sales service guarantees.

Operating System: Industrial PC Customized Systems: Based on Linux or Windows IoT, deeply customized, retaining only essential drivers and services (such as touchscreens and network ports).

Drivers and Firmware: Industrial PCs offer 5-10 years of update support and have undergone rigorous compatibility testing.

Home PC Operating Systems (such as Windows 11 and macOS) have numerous background processes, high resource consumption, and are prone to fragmentation and lag over long-term use.

The P5000 series of new generation industrial computers have a modular design, capacitive touch/resistive touch options, and a molded shell. It presents an effective fusion of high reliability and industrial aesthetics, interpreting the sophisticated quality of industrial computers in industrial design. and technological fashion elements, it is the best choice for high-end smart equipment.

This series of products has high anti-interference design and strong scalability, which can meet the requirements for use in harsh industrial environments. It has good dustproof, heat dissipation, vibration resistance, and EMC performance. It has high system reliability and strong environmental applicability. It is a Products for industrial automation industry, medical informatization, and industrial field control applications.

In summary, the choice should be based on actual needs: industrial scenarios require high reliability and customization, while home or office scenarios are more suitable for economical and practical home computers.

The key difference between industrial and consumer computers lies in their design goals, application environments, and performance focuses: industrial computers are designed for harsh industrial environments, emphasizing high reliability, stability, and long-term durability; while consumer computers are geared towards everyday general-purpose scenarios, focusing on cost-effectiveness, ease of use, and stylish appearance.

The differences :

Application Scenarios and Environmental Adaptability: Industrial computers are widely used in industrial fields such as factory automation, requiring continuous operation 24/7 in harsh environments such as high temperature, high humidity, dust, and vibration. Home computers, on the other hand, are mainly used in milder environments such as home entertainment, office work, and study, with lower requirements for adaptability to extreme conditions.Typical scenarios include: factory automation, intelligent transportation, medical equipment, and outdoor monitoring, where tolerance for failure is extremely low (e.g., production line downtime can cause significant losses).

Reliability and Stability: Industrial computers utilize industrial-grade hardware components (such as wide-temperature processors and ECC memory), ensuring long-term stable operation and an extremely low failure rate through fanless design, reinforced casing, and dust and water-resistant structures (such as IP65 protection rating). Home computer hardware prioritizes consumer-grade cost-effectiveness and is more prone to failure under continuous high loads or harsh environments.

Industrial computer processors (CPUs) use low-power, highly stable industrial-grade chips (such as Intel Atom, Rockchip RK3568, and AMD G-Series).

They support wide-temperature operation (-40℃ to 85℃) and pass aging tests to ensure a 10-year lifespan. Industrial-grade DDR4 memory supports ECC error correction, automatically repairing data errors and preventing system crashes. SLC solid-state drives withstand over 100,000 write cycles, providing data retention for over 10 years.

Home computers, on the other hand, prioritize cost-effectiveness and versatility.

Hardware Design and Expandability

Core Components: Industrial PCs use rigorously selected durable components (such as industrial-grade SSDs) and support a wide operating temperature range of -20℃ to 60℃; consumer PCs mostly use consumer-grade hardware with a narrower operating temperature range.

Interfaces and Expansion: Industrial PCs are equipped with industrial interfaces such as RS-485 and CAN bus for easy connection to sensors, PLCs, and other devices; consumer PCs primarily use universal interfaces such as USB and HDMI.

Industrial field requirements are diverse, including the need to connect PLCs, sensors, barcode scanners, cameras, instruments, etc. In such cases, ordinary PCs often face a shortage of interfaces.

Industrial PCs not only come standard with multiple serial ports (COM), multiple USB ports, and multiple LAN ports, but some models also support CAN bus, fiber optic network ports, and PCIe slots.

Thermal Design: Industrial computers often employ passive cooling or industrial-grade fans to prevent dust accumulation; industrial PCs typically use fanless, passive cooling designs with a compact, vibration-resistant internal layout. This structure not only reduces the failure rate but also allows for flexible integration into various mechanical equipment or power distribution cabinets.

Home computers rely on active cooling, making their fans prone to damage.

Ordinary computers have rapid product updates and short component supply cycles, posing a potential risk for long-term projects or large-scale equipment deployments. Industrial PCs, however, emphasize long-term supply, stable compatibility, and after-sales service guarantees.

Operating System: Industrial PC Customized Systems: Based on Linux or Windows IoT, deeply customized, retaining only essential drivers and services (such as touchscreens and network ports).

Drivers and Firmware: Industrial PCs offer 5-10 years of update support and have undergone rigorous compatibility testing.

Home PC Operating Systems (such as Windows 11 and macOS) have numerous background processes, high resource consumption, and are prone to fragmentation and lag over long-term use.

The P5000 series industrial computers

The P5000 series of new generation industrial computers have a modular design, capacitive touch/resistive touch options, and a molded shell. It presents an effective fusion of high reliability and industrial aesthetics, interpreting the sophisticated quality of industrial computers in industrial design. and technological fashion elements, it is the best choice for high-end smart equipment.

This series of products has high anti-interference design and strong scalability, which can meet the requirements for use in harsh industrial environments. It has good dustproof, heat dissipation, vibration resistance, and EMC performance. It has high system reliability and strong environmental applicability. It is a Products for industrial automation industry, medical informatization, and industrial field control applications.

In summary, the choice should be based on actual needs: industrial scenarios require high reliability and customization, while home or office scenarios are more suitable for economical and practical home computers.

Recommended

.jpg)