What are the advantages of industrial PC

2025-05-16

With the rapid evolution of Industry 4.0 and Smart Manufacturing, the Industrial PC has become the core hub connecting physical production and digital management. With its unique advantages of high reliability, environmental adaptability, and flexible scalability, the Industrial PC continues to solve efficiency and stability challenges for manufacturing, energy, transportation, and other industries.

Industrial PC (also known as embedded PC) is a highly reliable computer system designed specifically for industrial environments, and its core mission is to provide stable computing support for industrial equipment and ensure high-precision execution of repetitive tasks. Compared with commercial computers, it has three essential differences:

Hardware Architecture: With all-metal fanless design, wide-temperature industrial-grade components (-40°C to 85°C), and a shock- and moisture-resistant body, it can operate continuously in extreme environments such as dust, vibration, and high temperatures.

Life Cycle: The average iteration cycle of commercial PCs is 1-2 years, while the life cycle of industrial PCs can reach 5-7 years, and the original manufacturer provides long-term firmware updates and spare parts supply to reduce the cost of frequent equipment replacement.

Functionality: Built-in RS232/485, CAN bus, PROFINET and other industrial-grade interfaces, supporting 24-hour uninterrupted operation, designed for connecting PLCs, sensors, robots and other industrial equipment.

The full-scenario adaptability of industrial PCs comes from triple hardcore design:

Physical Protection: IP65/IP67-rated dustproof and waterproof body, MIL-STD-810G vibration-resistant standard, can withstand 50G shock and continuous vibration, suitable for automotive production lines, mines and other harsh scenarios.

Fanless cooling: passive cooling through heat pipes and large-area cooling fins to avoid traditional fans from accumulating dust, and the average annual downtime of a food processing plant dropped from 48 hours to 6 hours after introduction.

Industrial-grade components: Wide-temperature SSDs (-30°C low-temperature resistant), ECC error-correcting memory, and long-life capacitors ensure stable operation for 7×24 hours, with a failure rate 80% lower than that of commercial PCs.

Facing the complex demands of smart factories, the hardware configuration of industrial PCs hits the pain point directly:

Processor performance: equipped with Intel Core i7/i9 industrial-grade processor or AMD embedded APU, supporting real-time operating system (RTOS), it can complete tasks such as machine vision inspection and robot path planning in milliseconds.

Storage solution: standard SLC/MLC SSD (100,000 writes) and RAID disk array, a semiconductor factory using industrial PC to achieve real-time analysis of wafer defects, inspection efficiency increased by 200%.

The flexible configurability of the Industrial PC makes it the centerpiece of cross-industry solutions:

Interface richness: Native support for 4-8 COM serial ports, 2-4 Gigabit LAN ports, USB 3.2 Gen2, optional PCIe expansion cards (e.g. GPU, 4G LTE module), compatible with old devices and new sensors.

Diversified forms: Provide panel type touch all-in-one PC, DIN rail type fanless mainframe, explosion-proof industrial controller and other forms to meet the needs of the workshop operator's desk, outdoor equipment integration and other scenarios.

Software adaptability: pre-installed Windows IoT, Linux or customized industrial software. A medical equipment manufacturer shortened its product launch cycle by 30% by customizing the BIOS and brand logo.

Chip-level support: Intel/AMD industrial-grade processors offer a 5-7 year lifecycle, with EOL notices issued 6-12 months in advance by the original manufacturer, avoiding the risk of sudden shutdowns.

Ease of Maintenance: Hot-swappable hard disk and redundant power supply design compresses troubleshooting time from hourly to minute level, effectively reducing O&M costs.

Hardware-level protection: Integrated TPM 2.0 security chip and AES-256 encryption prevent production data leakage; BIOS whitelisting mechanism prevents unauthorized firmware tampering.

Remote Operation and Maintenance: Supports Intel vPro/AMT remote management, real-time monitoring of device status and pushing firmware updates. A new energy vehicle manufacturer has improved system vulnerability repair efficiency by 90% through this feature.

Protocol Conversion: Built-in OPC UA server converts field protocols such as Modbus, CANopen, etc. to MQTT/JSON, realizing rapid “cloud uploading” of old devices.

Edge computing: 90% of real-time data (e.g., equipment vibration analysis) is processed locally, and only key anomaly data is transmitted to the cloud, which has been used by a steel mill to reduce network bandwidth costs by 70%.

Industrial PCs need to meet stringent industry standards:

Safety Certification: CE, FCC and other certifications for chemical, medical and other compliance demanding scenarios.

Electromagnetic Compatibility: Low EMI design to avoid interference with precision instruments, compliant with industrial EMC standards.

Temperature: Define the operating temperature range (e.g. - 20°C to 60°C) and choose a wide-temperature or ruggedized model.

Protection: Choose IP65 for dusty environments, IP67 for humid environments, and explosion-proof certified models for chemical environments.

Light load (such as data acquisition): Intel Atom/Celeron processor, 4-8GB RAM.

Heavy load (such as image processing): Intel Core i7/i9 or AMD embedded processor, 16-32GB RAM + GPU acceleration.

Statistics of existing device interfaces (e.g. RS485, USB, network port) to ensure native support for industrial PCs and reduce adapter dependency.

Reserves PCIe/M.2 slots to cope with future 5G and AI module upgrade requirements.

Selects suppliers that provide more than 5 years of technical support and 7×24-hour response to ensure quick troubleshooting.

Requires manufacturers to provide customized services, which can maximize the shortening of the project deployment cycle.

Comprehensive initial purchase cost and 5-year operation and maintenance cost, long life cycle models, usually TCO is more than 30% lower than commercial PC.

The Industrial PC is more than just a computer, it is the infrastructure for the digital transformation of industry. From the automation of traditional factories to the remote monitoring and control of smart grids, it creates efficiency and value for enterprises with durability as its foundation, flexibility as its engine, and safety as its bottom line. For decision makers who are planning for Industry 4.0, choosing the right industrial PC means choosing to work with a partner who is “reliable and evolving over time”.

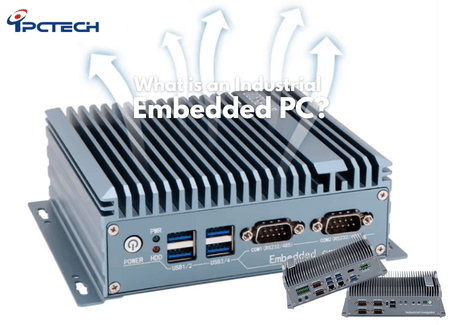

What is an Industrial PC?

Industrial PC (also known as embedded PC) is a highly reliable computer system designed specifically for industrial environments, and its core mission is to provide stable computing support for industrial equipment and ensure high-precision execution of repetitive tasks. Compared with commercial computers, it has three essential differences:

Hardware Architecture: With all-metal fanless design, wide-temperature industrial-grade components (-40°C to 85°C), and a shock- and moisture-resistant body, it can operate continuously in extreme environments such as dust, vibration, and high temperatures.

Life Cycle: The average iteration cycle of commercial PCs is 1-2 years, while the life cycle of industrial PCs can reach 5-7 years, and the original manufacturer provides long-term firmware updates and spare parts supply to reduce the cost of frequent equipment replacement.

Functionality: Built-in RS232/485, CAN bus, PROFINET and other industrial-grade interfaces, supporting 24-hour uninterrupted operation, designed for connecting PLCs, sensors, robots and other industrial equipment.

Which features make a PC an industrial Panel PC?

Survival Power in Extreme Environments

The full-scenario adaptability of industrial PCs comes from triple hardcore design:

Physical Protection: IP65/IP67-rated dustproof and waterproof body, MIL-STD-810G vibration-resistant standard, can withstand 50G shock and continuous vibration, suitable for automotive production lines, mines and other harsh scenarios.

Fanless cooling: passive cooling through heat pipes and large-area cooling fins to avoid traditional fans from accumulating dust, and the average annual downtime of a food processing plant dropped from 48 hours to 6 hours after introduction.

Industrial-grade components: Wide-temperature SSDs (-30°C low-temperature resistant), ECC error-correcting memory, and long-life capacitors ensure stable operation for 7×24 hours, with a failure rate 80% lower than that of commercial PCs.

High-performance real-time computing

Facing the complex demands of smart factories, the hardware configuration of industrial PCs hits the pain point directly:

Processor performance: equipped with Intel Core i7/i9 industrial-grade processor or AMD embedded APU, supporting real-time operating system (RTOS), it can complete tasks such as machine vision inspection and robot path planning in milliseconds.

Storage solution: standard SLC/MLC SSD (100,000 writes) and RAID disk array, a semiconductor factory using industrial PC to achieve real-time analysis of wafer defects, inspection efficiency increased by 200%.

Modular customization

The flexible configurability of the Industrial PC makes it the centerpiece of cross-industry solutions:

Interface richness: Native support for 4-8 COM serial ports, 2-4 Gigabit LAN ports, USB 3.2 Gen2, optional PCIe expansion cards (e.g. GPU, 4G LTE module), compatible with old devices and new sensors.

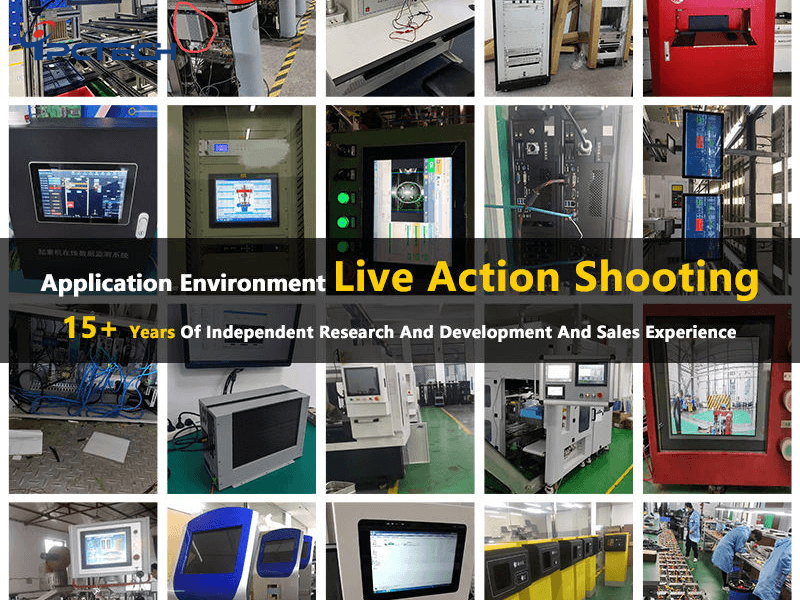

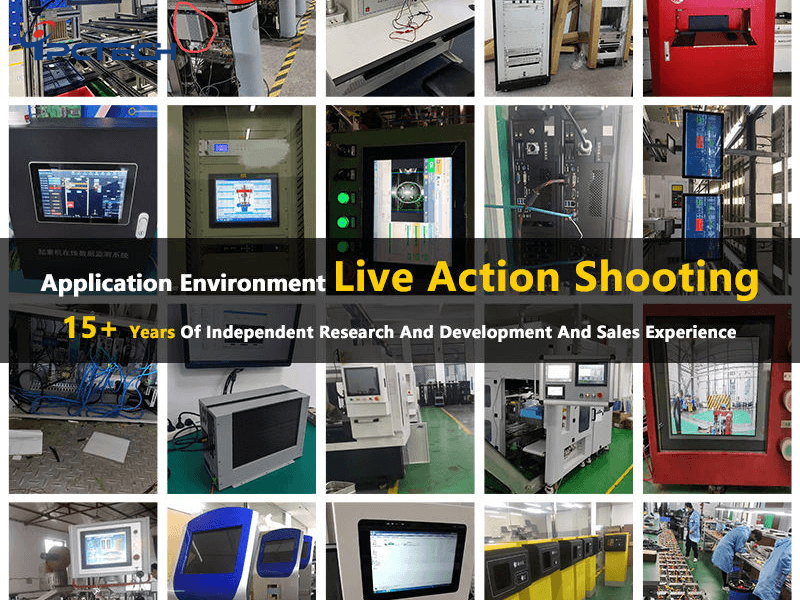

Diversified forms: Provide panel type touch all-in-one PC, DIN rail type fanless mainframe, explosion-proof industrial controller and other forms to meet the needs of the workshop operator's desk, outdoor equipment integration and other scenarios.

Software adaptability: pre-installed Windows IoT, Linux or customized industrial software. A medical equipment manufacturer shortened its product launch cycle by 30% by customizing the BIOS and brand logo.

Long Lifecycle Management

The supply chain stability of industrial PCs brings long-term value to organizations:

Chip-level support: Intel/AMD industrial-grade processors offer a 5-7 year lifecycle, with EOL notices issued 6-12 months in advance by the original manufacturer, avoiding the risk of sudden shutdowns.

Ease of Maintenance: Hot-swappable hard disk and redundant power supply design compresses troubleshooting time from hourly to minute level, effectively reducing O&M costs.

Industrial Data Security

In the era of industrial Internet, the security features of industrial PCs are crucial:

Hardware-level protection: Integrated TPM 2.0 security chip and AES-256 encryption prevent production data leakage; BIOS whitelisting mechanism prevents unauthorized firmware tampering.

Remote Operation and Maintenance: Supports Intel vPro/AMT remote management, real-time monitoring of device status and pushing firmware updates. A new energy vehicle manufacturer has improved system vulnerability repair efficiency by 90% through this feature.

Seamless Integration

Industrial PCs are the bridge between traditional equipment and intelligent systems:

Protocol Conversion: Built-in OPC UA server converts field protocols such as Modbus, CANopen, etc. to MQTT/JSON, realizing rapid “cloud uploading” of old devices.

Edge computing: 90% of real-time data (e.g., equipment vibration analysis) is processed locally, and only key anomaly data is transmitted to the cloud, which has been used by a steel mill to reduce network bandwidth costs by 70%.

Compliance and Industry Certifications

Industrial PCs need to meet stringent industry standards:

Safety Certification: CE, FCC and other certifications for chemical, medical and other compliance demanding scenarios.

Electromagnetic Compatibility: Low EMI design to avoid interference with precision instruments, compliant with industrial EMC standards.

Key Considerations for Industrial PCs

Environmental adaptability

Temperature: Define the operating temperature range (e.g. - 20°C to 60°C) and choose a wide-temperature or ruggedized model.

Protection: Choose IP65 for dusty environments, IP67 for humid environments, and explosion-proof certified models for chemical environments.

Performance matching

Light load (such as data acquisition): Intel Atom/Celeron processor, 4-8GB RAM.

Heavy load (such as image processing): Intel Core i7/i9 or AMD embedded processor, 16-32GB RAM + GPU acceleration.

Interface and scalability

Statistics of existing device interfaces (e.g. RS485, USB, network port) to ensure native support for industrial PCs and reduce adapter dependency.

Reserves PCIe/M.2 slots to cope with future 5G and AI module upgrade requirements.

Service and Support

Selects suppliers that provide more than 5 years of technical support and 7×24-hour response to ensure quick troubleshooting.

Requires manufacturers to provide customized services, which can maximize the shortening of the project deployment cycle.

TCO (Total Cost of Ownership)

Comprehensive initial purchase cost and 5-year operation and maintenance cost, long life cycle models, usually TCO is more than 30% lower than commercial PC.

Conclusion

The Industrial PC is more than just a computer, it is the infrastructure for the digital transformation of industry. From the automation of traditional factories to the remote monitoring and control of smart grids, it creates efficiency and value for enterprises with durability as its foundation, flexibility as its engine, and safety as its bottom line. For decision makers who are planning for Industry 4.0, choosing the right industrial PC means choosing to work with a partner who is “reliable and evolving over time”.

Recommended