Industrial Computer vs Commercial Computer

2025-06-19

With the wave of digitization sweeping the world today, computers, as the core equipment for information processing and control, have been deeply integrated into various fields. But did you know that the design, performance and functionality of computers used in different scenarios are vastly different? Today, we will focus on Industrial Computer and Commercial Computer to help organizations make better choices in digital transformation.

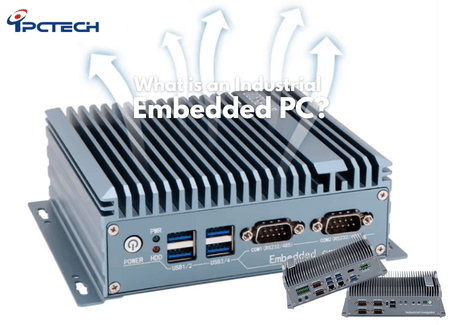

Industrial computers, as the name suggests, are computer devices designed and built for industrial environments. These devices need to operate stably under extreme conditions such as high temperature, low temperature, high dust, strong vibration, electromagnetic interference, etc., and at the same time support 7×24 hours of uninterrupted work. Industrial computers are widely used in manufacturing automation, energy monitoring, intelligent transportation, medical equipment and other fields, and are the key technical support for Industry 4.0 and intelligent manufacturing.

Commercial computers are aimed at the consumer market, mainly meeting the needs of daily office, entertainment, learning and other needs. From home desktops, thin and light laptops to corporate office computers, commercial computers focus on versatility and cost-effectiveness, pursuing a convenient operating experience and smooth basic performance, and are suitable for regular use in stable indoor environments.

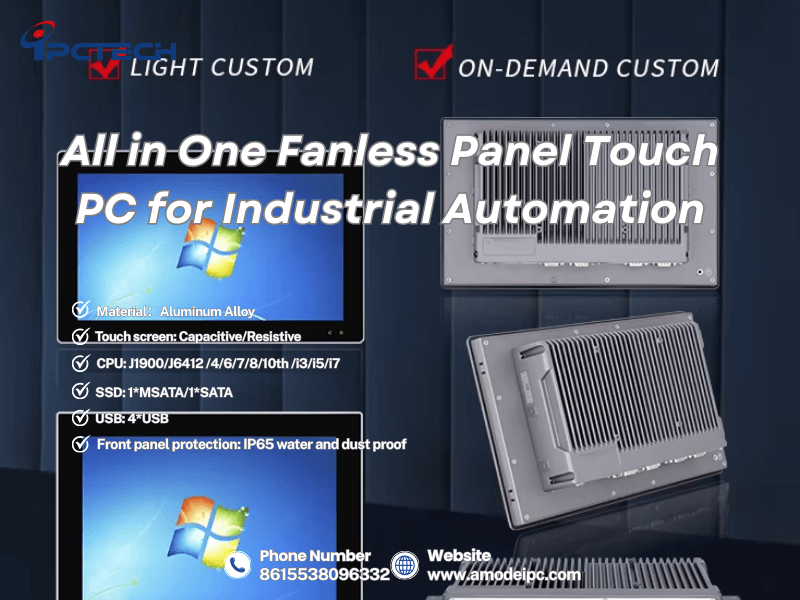

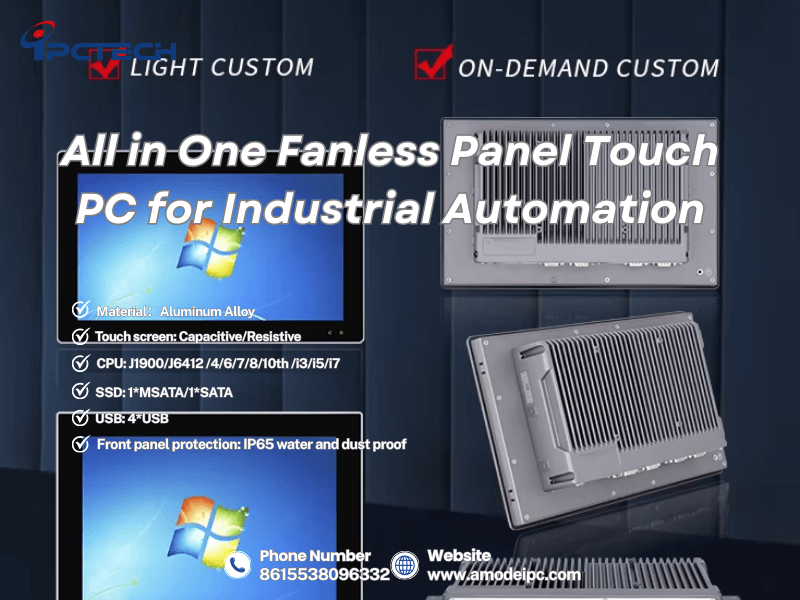

The core of industrial computer design is “reliability”. In order to cope with complex industrial environments, they adopt special designs in terms of structure, heat dissipation, and power management. For example, industrial computers are often equipped with full-metal reinforced chassis, which are dustproof, waterproof (IP65 and above), and impact-resistant to ensure that they can still operate normally under harsh working conditions.

Commercial computers pay more attention to “user experience and cost balance”. Under the premise of meeting the basic performance requirements, commercial computers pursue thin and light appearance, low-noise operation and convenient operation interface to adapt to the needs of use in comfortable environments such as offices and homes. At the same time, the standardized hardware configuration and mass production model enable effective cost control.

Industrial computers usually use industrial-grade chips and components. Take CPU as an example, industrial computers may be equipped with wide-temperature processors, which can work stably in extreme temperatures from -40℃ to 70℃; motherboards are made of industrial-grade PCBs, which have stronger electrical stability and anti-interference ability; storage devices are mostly industrial-grade solid-state drives (SSDs), which support wide-temperature operation, are shock-resistant and drop-proof, and guarantee data security.

Commercial computers use consumer-grade hardware, CPU, memory, hard disk and other components to meet the daily office, entertainment needs as the goal, focusing on cost-effective and balanced performance. For example, Intel Core series processors, which are common in home computers, provide smooth multitasking in indoor room temperature environments, but may experience performance degradation or even failure in extreme environments.

Industrial computers are typically designed for a 5-10 year lifespan with tens of thousands of hours of Mean Time Between Failure (MTBF). Their cooling systems are redundant and support a combination of active and passive cooling to ensure stable operation even in high-temperature environments. In addition, industrial computers are equipped with features such as power failure protection and self-start on incoming calls to ensure that the equipment quickly resumes work after an unexpected power failure, reducing the risk of production interruption.

Commercial computers are mostly used in 8-hour workdays, and the conventional cooling fan and heat sink design is sufficient to meet the needs of daily use. However, when running continuously for a long period of time under high loads or high temperatures, commercial computers are prone to overheating, downclocking, and crashing, and the life span of the hardware will be significantly shortened.

Industrial computers have an absolute advantage in environmental adaptability. In addition to wide-temperature operation, industrial computers can also resist strong electromagnetic interference, humidity, dust and other harsh conditions. For example, in the oil field data collection, industrial computers need to work continuously in the desert high temperature, sand and dust environment; in the intelligent transportation system, vehicle-mounted industrial computers have to adapt to bumps, vibration and frequent temperature changes.

Commercial computers usually operate in temperatures ranging from 0°C to 40°C and are suitable for use in air-conditioned indoor environments. If exposed to high temperatures, high humidity or dust, the hardware of commercial computers may accelerate aging, or even experience short-circuit or burnout.

Industrial computers have strong expandability and rich interface types. In order to meet the diverse needs of industrial equipment, industrial computers are usually equipped with multiple serial ports (RS232/RS485), parallel ports, PCI/PCIe expansion slots, support DIN rail mounting or embedded integration, and easy to connect with PLCs, sensors, meters and other equipment. In addition, industrial computers can also be customized with interface configurations according to customer needs to achieve highly flexible system integration.

Commercial computers have standardized interfaces, such as USB, HDMI, Ethernet ports, etc., which mainly meet the connection needs of daily office and consumer electronic devices. Its expandability is relatively limited, and the number of expansion slots on the motherboard is small, making it difficult to adapt to special equipment in the industrial field.

The initial purchase cost of an industrial computer is typically 2-3 times that of a commercial computer, but the long-term value is significant. Due to the high reliability and long lifespan of industrial computers, organizations can significantly reduce the cost of equipment maintenance and downtime losses. In addition, industrial PCs have customizable components, such as replacement wide-temperature hard drives and ruggedized power modules, which further enhance the applicability and durability of the equipment.

Commercial computers attract consumers with a lower price threshold for cost-sensitive individual users and SMEs. However, due to the fast hardware iteration, the refresh cycle of commercial computers is usually 3-5 years, and in the long run, the cost of equipment replacement and maintenance may exceed that of industrial computers.

In the manufacturing industry, industrial computers are the “key point” of automated production lines. From the precise control of CNC machine tools to the collaborative work of robots, industrial computers ensure the efficiency and stability of the production process through real-time data collection and analysis. For example, automotive manufacturers use industrial computers to connect sensors and actuators to realize automated control of welding, spraying and other processes, dramatically improving production efficiency and product quality.

The energy sector also relies on industrial computers to achieve intelligent monitoring. In the substation, industrial computer real-time collection of power parameters, analyze the operating status of the equipment, timely warning of the risk of failure; in the wind farm, industrial computers deployed in the wind turbine tower, to adapt to the high altitude, strong wind and sand environment, to achieve the remote control of the wind turbine and operation and maintenance management.

Medical equipment requires high stability and accuracy. As the core controllers of CT, MRI and other large-scale medical equipment, industrial computers need to work continuously in a dust-free, constant temperature operating room environment to ensure the accuracy of diagnostic data and the safety of equipment operation.

In the office scenario, commercial computers are the basic tools for the daily operation of enterprises. From document processing, data reporting to video conferencing, commercial computers fulfill most office needs with their cost-effectiveness and ease of use. For example, small and medium-sized enterprises (SMEs) use commercial desktops to build office networks, which not only reduces IT investment costs, but also ensures that employees work efficiently.

In the consumer sector, commercial computers are even more indispensable. Home gaming consoles, thin and light notebooks, all-in-one PCs and other devices bring immersive entertainment enjoyment to users through powerful graphics processing capabilities and smooth system experience. In addition, commercial computers are also widely used in the field of education, such as smart classrooms, online learning platforms, etc., to promote the development of education informatization.

When choosing industrial computers or commercial computers, the first thing you need to do is to clarify the use of the equipment and the core needs of the scene. If the equipment needs to operate in high temperature, humidity, vibration and other harsh environments, or the need for 7 × 24 hours of uninterrupted work, industrial computers is undoubtedly the best choice; if only used for office document processing, home entertainment and other conventional scenarios, commercial computers are sufficient to meet the needs.

According to the actual application load, evaluate the performance configuration of the computer. In industrial scenarios, focus on CPU computing power, memory capacity, data storage speed and other indicators; at the same time, ensure that the device has enough interfaces and expansion capabilities to adapt to possible future functionality upgrades. In commercial scenarios, a more cost-effective configuration can be selected according to the budget, taking into account the smoothness of daily use and cost control.

In addition to the initial purchase cost, you also need to consider the full life cycle cost of the equipment. Industrial computers, although more expensive, but strong stability, low maintenance frequency, suitable for industries with high reliability requirements; commercial computers are suitable for the pursuit of short-term cost-effective, frequent hardware update scenarios. In addition, the choice of suppliers with perfect after-sales service can effectively reduce the risk of equipment maintenance.

What is Industrial Computer?

Industrial computers, as the name suggests, are computer devices designed and built for industrial environments. These devices need to operate stably under extreme conditions such as high temperature, low temperature, high dust, strong vibration, electromagnetic interference, etc., and at the same time support 7×24 hours of uninterrupted work. Industrial computers are widely used in manufacturing automation, energy monitoring, intelligent transportation, medical equipment and other fields, and are the key technical support for Industry 4.0 and intelligent manufacturing.

What is Commercial PC?

Commercial computers are aimed at the consumer market, mainly meeting the needs of daily office, entertainment, learning and other needs. From home desktops, thin and light laptops to corporate office computers, commercial computers focus on versatility and cost-effectiveness, pursuing a convenient operating experience and smooth basic performance, and are suitable for regular use in stable indoor environments.

Industrial PC vs Commercial PC

| Comparison Dimensions | Industrial Computers | Commercial Computers |

| Design Objectives | Adapt to harsh environments (high temperature, dust, vibration, etc.) | Meet the cost - effectiveness requirements of daily office work and entertainment |

| Hardware Configuration | - Adopt industrial - grade chips (such as wide - temperature CPUs) | - Consumer - grade hardware (such as home - use CPUs, ordinary motherboards) |

| - Reinforced motherboards and dust - proof cases | - Focus on appearance design and portability | |

| - Support modular expansion | ||

| Stability and Durability | - Support 7×24 hours of uninterrupted operation | - Conventional heat dissipation design, suitable for 8 - hour working system |

| - Resist electromagnetic interference and adapt to wide voltage | - Weak anti - interference ability | |

| - Long Mean Time Between Failures (MTBF) | ||

| Environmental Adaptability | - Wide working temperature range (-40°C ~ 70°C) | - Suitable for indoor normal temperature environment (0°C ~ 40°C) |

| - Dust - proof and waterproof (IP65 + protection level) | - No special protection design | |

| Expandability and Interfaces | - Multiple serial ports, PCI/PCIe expansion slots | - Conventional USB and HDMI interfaces |

| - Support DIN rail installation and embedded integration | - Limited expandability, mainly with standardized interfaces | |

| Cost and Maintenance | - High initial cost, but low long - term maintenance cost | - Low initial cost, maintenance depends on standardized accessories |

| - Customizable components (such as wide - temperature hard disks) | - Fast upgrade iteration, short hardware service life |

Differences in Design Goals and Philosophy

The core of industrial computer design is “reliability”. In order to cope with complex industrial environments, they adopt special designs in terms of structure, heat dissipation, and power management. For example, industrial computers are often equipped with full-metal reinforced chassis, which are dustproof, waterproof (IP65 and above), and impact-resistant to ensure that they can still operate normally under harsh working conditions.

Commercial computers pay more attention to “user experience and cost balance”. Under the premise of meeting the basic performance requirements, commercial computers pursue thin and light appearance, low-noise operation and convenient operation interface to adapt to the needs of use in comfortable environments such as offices and homes. At the same time, the standardized hardware configuration and mass production model enable effective cost control.

Hardware Configuration

Industrial computers usually use industrial-grade chips and components. Take CPU as an example, industrial computers may be equipped with wide-temperature processors, which can work stably in extreme temperatures from -40℃ to 70℃; motherboards are made of industrial-grade PCBs, which have stronger electrical stability and anti-interference ability; storage devices are mostly industrial-grade solid-state drives (SSDs), which support wide-temperature operation, are shock-resistant and drop-proof, and guarantee data security.

Commercial computers use consumer-grade hardware, CPU, memory, hard disk and other components to meet the daily office, entertainment needs as the goal, focusing on cost-effective and balanced performance. For example, Intel Core series processors, which are common in home computers, provide smooth multitasking in indoor room temperature environments, but may experience performance degradation or even failure in extreme environments.

Stability and Durability

Industrial computers are typically designed for a 5-10 year lifespan with tens of thousands of hours of Mean Time Between Failure (MTBF). Their cooling systems are redundant and support a combination of active and passive cooling to ensure stable operation even in high-temperature environments. In addition, industrial computers are equipped with features such as power failure protection and self-start on incoming calls to ensure that the equipment quickly resumes work after an unexpected power failure, reducing the risk of production interruption.

Commercial computers are mostly used in 8-hour workdays, and the conventional cooling fan and heat sink design is sufficient to meet the needs of daily use. However, when running continuously for a long period of time under high loads or high temperatures, commercial computers are prone to overheating, downclocking, and crashing, and the life span of the hardware will be significantly shortened.

Environmental Adaptability

Industrial computers have an absolute advantage in environmental adaptability. In addition to wide-temperature operation, industrial computers can also resist strong electromagnetic interference, humidity, dust and other harsh conditions. For example, in the oil field data collection, industrial computers need to work continuously in the desert high temperature, sand and dust environment; in the intelligent transportation system, vehicle-mounted industrial computers have to adapt to bumps, vibration and frequent temperature changes.

Commercial computers usually operate in temperatures ranging from 0°C to 40°C and are suitable for use in air-conditioned indoor environments. If exposed to high temperatures, high humidity or dust, the hardware of commercial computers may accelerate aging, or even experience short-circuit or burnout.

Expandability and Interfaces

Industrial computers have strong expandability and rich interface types. In order to meet the diverse needs of industrial equipment, industrial computers are usually equipped with multiple serial ports (RS232/RS485), parallel ports, PCI/PCIe expansion slots, support DIN rail mounting or embedded integration, and easy to connect with PLCs, sensors, meters and other equipment. In addition, industrial computers can also be customized with interface configurations according to customer needs to achieve highly flexible system integration.

Commercial computers have standardized interfaces, such as USB, HDMI, Ethernet ports, etc., which mainly meet the connection needs of daily office and consumer electronic devices. Its expandability is relatively limited, and the number of expansion slots on the motherboard is small, making it difficult to adapt to special equipment in the industrial field.

Cost and Maintenance

The initial purchase cost of an industrial computer is typically 2-3 times that of a commercial computer, but the long-term value is significant. Due to the high reliability and long lifespan of industrial computers, organizations can significantly reduce the cost of equipment maintenance and downtime losses. In addition, industrial PCs have customizable components, such as replacement wide-temperature hard drives and ruggedized power modules, which further enhance the applicability and durability of the equipment.

Commercial computers attract consumers with a lower price threshold for cost-sensitive individual users and SMEs. However, due to the fast hardware iteration, the refresh cycle of commercial computers is usually 3-5 years, and in the long run, the cost of equipment replacement and maintenance may exceed that of industrial computers.

Applications of industrial computers

In the manufacturing industry, industrial computers are the “key point” of automated production lines. From the precise control of CNC machine tools to the collaborative work of robots, industrial computers ensure the efficiency and stability of the production process through real-time data collection and analysis. For example, automotive manufacturers use industrial computers to connect sensors and actuators to realize automated control of welding, spraying and other processes, dramatically improving production efficiency and product quality.

The energy sector also relies on industrial computers to achieve intelligent monitoring. In the substation, industrial computer real-time collection of power parameters, analyze the operating status of the equipment, timely warning of the risk of failure; in the wind farm, industrial computers deployed in the wind turbine tower, to adapt to the high altitude, strong wind and sand environment, to achieve the remote control of the wind turbine and operation and maintenance management.

Medical equipment requires high stability and accuracy. As the core controllers of CT, MRI and other large-scale medical equipment, industrial computers need to work continuously in a dust-free, constant temperature operating room environment to ensure the accuracy of diagnostic data and the safety of equipment operation.

Applications of Commercial Computers

In the office scenario, commercial computers are the basic tools for the daily operation of enterprises. From document processing, data reporting to video conferencing, commercial computers fulfill most office needs with their cost-effectiveness and ease of use. For example, small and medium-sized enterprises (SMEs) use commercial desktops to build office networks, which not only reduces IT investment costs, but also ensures that employees work efficiently.

In the consumer sector, commercial computers are even more indispensable. Home gaming consoles, thin and light notebooks, all-in-one PCs and other devices bring immersive entertainment enjoyment to users through powerful graphics processing capabilities and smooth system experience. In addition, commercial computers are also widely used in the field of education, such as smart classrooms, online learning platforms, etc., to promote the development of education informatization.

How to make the right decision: industrial computers VS Commercial Computers?

When choosing industrial computers or commercial computers, the first thing you need to do is to clarify the use of the equipment and the core needs of the scene. If the equipment needs to operate in high temperature, humidity, vibration and other harsh environments, or the need for 7 × 24 hours of uninterrupted work, industrial computers is undoubtedly the best choice; if only used for office document processing, home entertainment and other conventional scenarios, commercial computers are sufficient to meet the needs.

Evaluation of performance and scalability

According to the actual application load, evaluate the performance configuration of the computer. In industrial scenarios, focus on CPU computing power, memory capacity, data storage speed and other indicators; at the same time, ensure that the device has enough interfaces and expansion capabilities to adapt to possible future functionality upgrades. In commercial scenarios, a more cost-effective configuration can be selected according to the budget, taking into account the smoothness of daily use and cost control.

Consider long-term cost and maintenance

In addition to the initial purchase cost, you also need to consider the full life cycle cost of the equipment. Industrial computers, although more expensive, but strong stability, low maintenance frequency, suitable for industries with high reliability requirements; commercial computers are suitable for the pursuit of short-term cost-effective, frequent hardware update scenarios. In addition, the choice of suppliers with perfect after-sales service can effectively reduce the risk of equipment maintenance.

Recommended