How long does an industrial computer last

2025-06-23

In today's era of rapid technological development, industrial computers, as the core equipment of industrial automation and intelligence, are widely used in manufacturing, energy, medical, transportation and many other fields. From the precision control of automobile production lines to the real-time monitoring of energy grids; from the precise calculation of medical equipment to the intelligent scheduling of traffic signals, industrial computers play a crucial role. However, for enterprises, the service life of industrial computers is a key issue, which directly affects the enterprise's investment decisions, equipment renewal planning and operating costs. So, how long can industrial computers actually use it?

Industrial computers and ordinary computers in the design purpose and application scenarios there are significant differences, which also led to their differences in life. Ordinary computers are mainly oriented to the daily office, entertainment and other common environments, focusing on the user experience and the diversity of functions, and updated quickly to meet the ever-changing market demand. Generally speaking, the average lifespan of ordinary computers is around 3 - 5 years, and with the rapid iteration of technology, many users will take the initiative to replace their equipment with more advanced ones. Industrial computers, on the other hand, are designed to adapt to harsh industrial environments, such as high temperature, high humidity, dusty and strong vibration scenarios. It utilizes special designs and quality components with higher stability, reliability and durability for a relatively longer life expectancy.

Factors affecting the life of industrial computers are multifaceted, mainly including hardware factors, environmental factors and maintenance factors.

Component quality

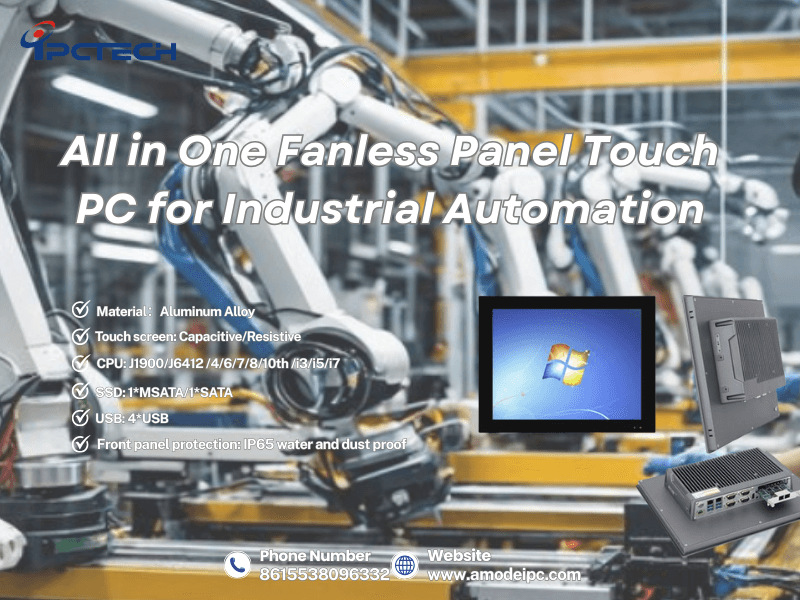

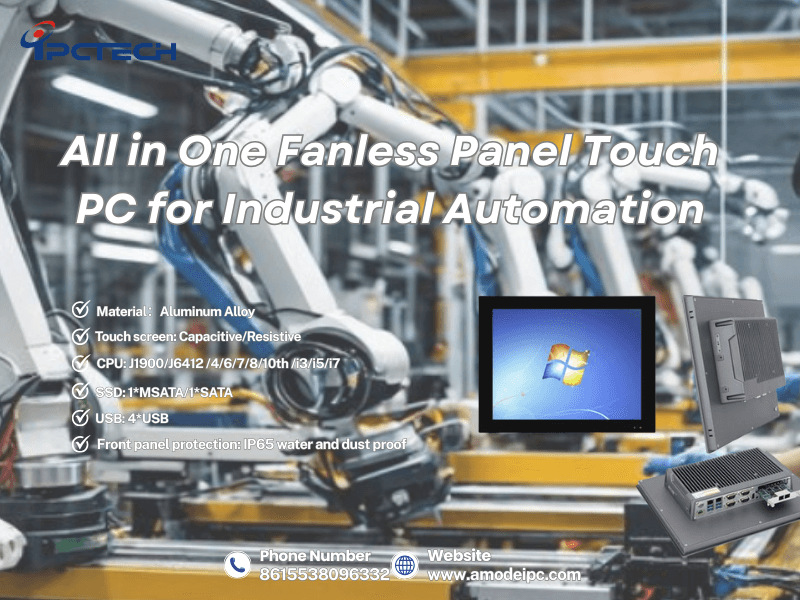

industrial-grade motherboards, high-performance processors, durable memory and other key components have been rigorously tested and screened during the design and manufacturing process, and are able to withstand higher operating pressure and harsher environmental conditions. ipctec uses industrial-grade motherboards with reinforced aluminum alloy materials and high-quality electronic components, which provide stronger anti-interference capabilities and longer service life; high-performance processors It is able to maintain stable performance under prolonged high-load operation and reduce failures caused by overheating, arithmetic errors and other problems. On the contrary, the use of poor-quality components will not only reduce the overall performance of industrial computers, but also very easy to cause failures, significantly shortening the service life of the equipment.

Heat dissipation design

In industrial environments, high temperature is the “number one killer” of electronic components. Prolonged high-temperature operation accelerates the aging of electronic components, reduces their performance, and even leads to component damage. In order to cope with this problem, industrial computers use a variety of heat dissipation methods, such as fan cooling, heat sink cooling, liquid cooling cooling and so on. Fan cooling takes away heat by forcing the air to flow, heat sink cooling utilizes the thermal conductivity of metal to dissipate heat into the air, and liquid cooling efficiently reduces the temperature by virtue of the circulation of coolant. Reasonable heat dissipation design can effectively control the internal temperature of the computer and extend the service life of the hardware.

Protection Level

Industrial computers usually have a high IP protection level, IP65 means that the equipment is dustproof and waterproof, which can effectively prevent dust and moisture from intruding into the interior of the computer, reduce the risk of short circuit, corrosion and other failures due to the accumulation of dust and moisture erosion, thus extending the service life of the equipment.

Environmental factors

Environmental factors have a direct and significant impact on the life of an industrial computer.

Temperature and Humidity

Extreme high or low temperature environments can cause damage to industrial computer hardware. In a high-temperature environment, the working performance of electronic components will be affected, and the computing speed of the chip may be reduced, or even crash; at the same time, high temperatures will accelerate the aging of components such as capacitors and resistors. In a low-temperature environment, the battery life will be reduced, and the read/write performance of hard disk and other storage devices will also be affected. High humidity environment is likely to lead to short circuit of the motherboard, corrosion of metal parts, and then lead to failure. Generally speaking, the appropriate operating temperature range for industrial computers is between 0℃ - 50℃ and relative humidity between 20% - 80%, beyond which the life of the equipment will be negatively affected.

Dust and Contaminants

Dust and contaminants are also a major challenge for industrial computers. In dusty industrial environments, dust can gradually accumulate inside the computer, blocking heat dissipation channels and affecting the effectiveness of heat dissipation, resulting in higher equipment temperatures; at the same time, dust can also cause electrical short circuits, damaging electronic components. In environments with chemical pollutants, such as chemical plants and printing and dyeing factories, chemical substances may react chemically with the metal parts inside the computer, accelerating the corrosion and damage of the parts. Therefore, in these environments, industrial computers require special protective measures, such as the use of dust covers and the installation of air filters, to maintain the normal operation and life of the equipment.

Vibration and Shock

Vibration and shock are also more common in industrial scenarios, which are generated by the operation of factory equipment, bumps during transportation, etc. These external forces can lead to problems such as loose solder joints in the computer's internal components and damage to the hard disk. In order to reduce such damage, industrial computers usually adopt anti-vibration design and reinforcement measures, including the use of anti-vibration mounts, hard disk reinforcement, etc., in order to improve the equipment's vibration-resistant capability and extend its service life.

Regular Cleaning

Regular cleaning is basic maintenance. Dust on the computer casing and internal components needs to be cleaned regularly, and it is generally recommended that a full cleaning be performed every 3 - 6 months. When cleaning, you can use special cleaning tools, such as compressed air canisters, anti-static brushes, etc., to remove dust from heat sinks, fans, circuit boards and other parts. This will effectively maintain the heat dissipation performance of the device, prevent short circuits and other faults caused by dust accumulation, and thus extend the service life of the device.

Software Update

Software update is also an important part of maintenance. Operating systems, drivers and other software updates can not only repair known vulnerabilities, but also improve system performance and ensure the stability of equipment operation. In the update of the operating system, it may be possible to optimize the allocation of resources and improve the operating speed of the computer; the update of the driver can solve the compatibility problem between the hardware and the software, and avoid equipment failure caused by incompatible drivers. If the software is not updated in a timely manner, compatibility problems may occur, making the device run unstably or even facing security risks, thus affecting the life of the device.

Hardware Testing and Replacement

Hardware testing and replacement is also essential. Regularly test the hardware, such as using memory testing tools to check whether the memory is faulty, detecting whether the hard disk has bad sectors through hard disk scanning tools, and so on. Based on the test results, timely replacement of aging and damaged hardware components can maintain the stability of the overall computer performance and extend the service life of the equipment.

Based on extensive case studies and industry data, industrial computers have different life ranges under different conditions.

In order to extend the life of industrial computers, companies can adopt the following strategies.

According to the actual use of the environment and needs, it is crucial to select industrial computers with the appropriate level of protection and performance configuration. For example, in the chemical industry, due to the presence of chemical pollutants, should choose to have a high level of protection and corrosion-resistant industrial computers; in the food processing industry, in order to meet the hygiene requirements, the need to choose easy to clean, good protective performance of the equipment; in the mining and other dusty, vibrating environment, it is necessary to choose dustproof, shock-resistant industrial computers with excellent performance.

enterprises can take a series of measures to improve the working environment of industrial computers, such as the installation of air conditioning in the workshop to regulate the temperature and humidity, equipped with a dust cover for the computer to reduce dust intrusion, the use of shock-absorbing brackets to reduce the impact of vibration and so on. These measures can effectively reduce the loss of hardware and extend the service life of the equipment.

In summary, the service life of industrial computers is the result of hardware configuration, operating environment, maintenance and management of multiple factors, not constant. High-quality industrial-grade components, appropriate use of the environment and scientific maintenance strategy is the key to extend the life of the equipment.

As a professional enterprise in the field of industrial computers for over 20 years, ipctech always provides customers with highly reliable and high-performance industrial computer solutions with excellent technical strength and innovative spirit. Our products use high-quality hardware, with excellent heat dissipation and protection design, and can easily cope with all kinds of complex industrial scenarios. At the same time, we also provide customers with comprehensive environmental adaptation programs and professional maintenance guidance to help enterprises effectively extend the service life of equipment and reduce operating costs.

In the accelerated development of industrial intelligence, scientific management of industrial computer life is essential for enterprises to enhance competitiveness. If you have industrial computer related needs, please feel free to contact ipctech for a quotation, we will provide you with professional products and services to help your business develop efficiently!

Which is better: industrial computers VS ordinary computers?

Industrial computers and ordinary computers in the design purpose and application scenarios there are significant differences, which also led to their differences in life. Ordinary computers are mainly oriented to the daily office, entertainment and other common environments, focusing on the user experience and the diversity of functions, and updated quickly to meet the ever-changing market demand. Generally speaking, the average lifespan of ordinary computers is around 3 - 5 years, and with the rapid iteration of technology, many users will take the initiative to replace their equipment with more advanced ones. Industrial computers, on the other hand, are designed to adapt to harsh industrial environments, such as high temperature, high humidity, dusty and strong vibration scenarios. It utilizes special designs and quality components with higher stability, reliability and durability for a relatively longer life expectancy.

Factors affecting the life of industrial computers

Factors affecting the life of industrial computers are multifaceted, mainly including hardware factors, environmental factors and maintenance factors.

Hardware factors

Hardware factors are the basis for determining the life span of industrial computers.Component quality

industrial-grade motherboards, high-performance processors, durable memory and other key components have been rigorously tested and screened during the design and manufacturing process, and are able to withstand higher operating pressure and harsher environmental conditions. ipctec uses industrial-grade motherboards with reinforced aluminum alloy materials and high-quality electronic components, which provide stronger anti-interference capabilities and longer service life; high-performance processors It is able to maintain stable performance under prolonged high-load operation and reduce failures caused by overheating, arithmetic errors and other problems. On the contrary, the use of poor-quality components will not only reduce the overall performance of industrial computers, but also very easy to cause failures, significantly shortening the service life of the equipment.

Heat dissipation design

In industrial environments, high temperature is the “number one killer” of electronic components. Prolonged high-temperature operation accelerates the aging of electronic components, reduces their performance, and even leads to component damage. In order to cope with this problem, industrial computers use a variety of heat dissipation methods, such as fan cooling, heat sink cooling, liquid cooling cooling and so on. Fan cooling takes away heat by forcing the air to flow, heat sink cooling utilizes the thermal conductivity of metal to dissipate heat into the air, and liquid cooling efficiently reduces the temperature by virtue of the circulation of coolant. Reasonable heat dissipation design can effectively control the internal temperature of the computer and extend the service life of the hardware.

Protection Level

Industrial computers usually have a high IP protection level, IP65 means that the equipment is dustproof and waterproof, which can effectively prevent dust and moisture from intruding into the interior of the computer, reduce the risk of short circuit, corrosion and other failures due to the accumulation of dust and moisture erosion, thus extending the service life of the equipment.

Environmental factors

Environmental factors have a direct and significant impact on the life of an industrial computer.

Temperature and Humidity

Extreme high or low temperature environments can cause damage to industrial computer hardware. In a high-temperature environment, the working performance of electronic components will be affected, and the computing speed of the chip may be reduced, or even crash; at the same time, high temperatures will accelerate the aging of components such as capacitors and resistors. In a low-temperature environment, the battery life will be reduced, and the read/write performance of hard disk and other storage devices will also be affected. High humidity environment is likely to lead to short circuit of the motherboard, corrosion of metal parts, and then lead to failure. Generally speaking, the appropriate operating temperature range for industrial computers is between 0℃ - 50℃ and relative humidity between 20% - 80%, beyond which the life of the equipment will be negatively affected.

Dust and Contaminants

Dust and contaminants are also a major challenge for industrial computers. In dusty industrial environments, dust can gradually accumulate inside the computer, blocking heat dissipation channels and affecting the effectiveness of heat dissipation, resulting in higher equipment temperatures; at the same time, dust can also cause electrical short circuits, damaging electronic components. In environments with chemical pollutants, such as chemical plants and printing and dyeing factories, chemical substances may react chemically with the metal parts inside the computer, accelerating the corrosion and damage of the parts. Therefore, in these environments, industrial computers require special protective measures, such as the use of dust covers and the installation of air filters, to maintain the normal operation and life of the equipment.

Vibration and Shock

Vibration and shock are also more common in industrial scenarios, which are generated by the operation of factory equipment, bumps during transportation, etc. These external forces can lead to problems such as loose solder joints in the computer's internal components and damage to the hard disk. In order to reduce such damage, industrial computers usually adopt anti-vibration design and reinforcement measures, including the use of anti-vibration mounts, hard disk reinforcement, etc., in order to improve the equipment's vibration-resistant capability and extend its service life.

Maintenance factors

Maintenance factors also play a key role in the life of an industrial computer.Regular Cleaning

Regular cleaning is basic maintenance. Dust on the computer casing and internal components needs to be cleaned regularly, and it is generally recommended that a full cleaning be performed every 3 - 6 months. When cleaning, you can use special cleaning tools, such as compressed air canisters, anti-static brushes, etc., to remove dust from heat sinks, fans, circuit boards and other parts. This will effectively maintain the heat dissipation performance of the device, prevent short circuits and other faults caused by dust accumulation, and thus extend the service life of the device.

Software Update

Software update is also an important part of maintenance. Operating systems, drivers and other software updates can not only repair known vulnerabilities, but also improve system performance and ensure the stability of equipment operation. In the update of the operating system, it may be possible to optimize the allocation of resources and improve the operating speed of the computer; the update of the driver can solve the compatibility problem between the hardware and the software, and avoid equipment failure caused by incompatible drivers. If the software is not updated in a timely manner, compatibility problems may occur, making the device run unstably or even facing security risks, thus affecting the life of the device.

Hardware Testing and Replacement

Hardware testing and replacement is also essential. Regularly test the hardware, such as using memory testing tools to check whether the memory is faulty, detecting whether the hard disk has bad sectors through hard disk scanning tools, and so on. Based on the test results, timely replacement of aging and damaged hardware components can maintain the stability of the overall computer performance and extend the service life of the equipment.

Common life ranges for industrial PCs

Based on extensive case studies and industry data, industrial computers have different life ranges under different conditions.

Lifespan under ideal conditions

Under ideal conditions, i.e., suitable temperature and humidity, low dust, no vibration and well-maintained, industrial computers can be used for 10 - 15 years. At this point, the hardware components are able to operate in a more stable environment, reducing wear and tear due to environmental factors, and with regular maintenance, the equipment can maintain good performance and stability.Lifespan in a typical industrial environment

In a typical industrial environment with good maintenance, the lifespan of an industrial computer is 7 - 10 years. Although the general industrial environment there is a certain amount of dust, vibration and other factors, but through appropriate protective measures and good maintenance, can still effectively reduce the wear and tear of the equipment to ensure its normal operation for a longer period of time.Lifespan in Harsh Environments

In harsh environments, such as high temperature, high humidity, dusty, strong vibration and insufficient maintenance, the lifespan of industrial computers may be shortened to 5 - 7 years or even less. Harsh environments accelerate hardware aging and damage, and lack of maintenance prevents potential problems from being detected and resolved in a timely manner, resulting in frequent equipment failures and a significantly shorter lifespan.Strategies to Extend the Life of Industrial Panel PCs

In order to extend the life of industrial computers, companies can adopt the following strategies.

Choose the right equipment

According to the actual use of the environment and needs, it is crucial to select industrial computers with the appropriate level of protection and performance configuration. For example, in the chemical industry, due to the presence of chemical pollutants, should choose to have a high level of protection and corrosion-resistant industrial computers; in the food processing industry, in order to meet the hygiene requirements, the need to choose easy to clean, good protective performance of the equipment; in the mining and other dusty, vibrating environment, it is necessary to choose dustproof, shock-resistant industrial computers with excellent performance.

Optimize the use of the environment

enterprises can take a series of measures to improve the working environment of industrial computers, such as the installation of air conditioning in the workshop to regulate the temperature and humidity, equipped with a dust cover for the computer to reduce dust intrusion, the use of shock-absorbing brackets to reduce the impact of vibration and so on. These measures can effectively reduce the loss of hardware and extend the service life of the equipment.

In summary, the service life of industrial computers is the result of hardware configuration, operating environment, maintenance and management of multiple factors, not constant. High-quality industrial-grade components, appropriate use of the environment and scientific maintenance strategy is the key to extend the life of the equipment.

As a professional enterprise in the field of industrial computers for over 20 years, ipctech always provides customers with highly reliable and high-performance industrial computer solutions with excellent technical strength and innovative spirit. Our products use high-quality hardware, with excellent heat dissipation and protection design, and can easily cope with all kinds of complex industrial scenarios. At the same time, we also provide customers with comprehensive environmental adaptation programs and professional maintenance guidance to help enterprises effectively extend the service life of equipment and reduce operating costs.

In the accelerated development of industrial intelligence, scientific management of industrial computer life is essential for enterprises to enhance competitiveness. If you have industrial computer related needs, please feel free to contact ipctech for a quotation, we will provide you with professional products and services to help your business develop efficiently!

Recommended