What is the difference between PLC and industria PC

2025-05-16

Driven by the wave of Industry 4.0, automation has evolved from an option to improve efficiency to a necessity for business survival. The global manufacturing industry is deploying advanced control systems to improve production accuracy, reduce downtime and optimize costs. Programmable Logic Controllers (PLCs) and Industrial PCs (IPCs) are the two core technologies underpinning automation in this process. Although both of them serve industrial control scenarios, there are significant differences in their technical architecture, functional characteristics and scope of application.

PLC (Programmable Logic Controller) is a special computer designed for industrial environments, and its core function is to realize automated control of mechanical equipment through real-time logic operations. The hardware is modular and consists of a central processing unit (CPU), input/output (I/O) modules, power supply modules, and storage units. Unlike general-purpose computers, the PLC's operating system is a real-time operating system (RTOS), which ensures microsecond command execution accuracy and allows it to respond in real time to sensor signals (e.g., temperature, pressure) and control actuators (e.g., motors, valves).

Miniature PLC: Compact size (such as the size of the palm of your hand), integrated with basic I/O interfaces, suitable for single device control, such as start-stop logic control of small packaging machines.

Modular PLC: Supports flexible expansion of I/O modules (e.g. digital, analog, communication modules), suitable for complex production lines, e.g. collaborative control of robotic arms in automotive assembly workshops.

Rackmount PLC: With strong processing power and expansion capacity, it is commonly used in large industrial systems, such as centralized control systems (DCS) in the petrochemical field.

High reliability: fanless design, wide temperature operation (-40℃~70℃) and vibration-resistant structure allow stable operation in harsh environments such as dust and oil.

High real-time: based on scanning cycle mechanism, it ensures deterministic execution of control instructions, suitable for time-sensitive scenarios (e.g. high-speed filling production line).

Low programming threshold: supports graphical programming languages such as Ladder Logic, making it easy for field engineers to get started quickly.

Limited processing power: only supports simple logic operations, difficult to perform complex tasks such as machine learning and big data analysis.

Single-function: focused on industrial control, integration with IT systems (e.g. ERP, MES) requires additional gateway devices.

High cost of complex systems: when a large number of I/O modules or communication protocol conversions are required, the hardware cost increases exponentially.

An Industrial PC is an enhanced computer based on the general-purpose PC architecture, designed for industrial scenarios, running Windows, Linux, and other major operating systems. With the development of semiconductor technology, IPC can not only fulfill the control tasks of traditional PLC, but also carry multiple workloads such as HMI, edge computing, AI vision detection, etc. by integrating GPU (Graphics Processor), TPU (Tensor Processor) and NVMe SSD (High Speed Solid State Disk), and the core value is to reduce the number of hardware in the factory through “function integration”. Its core value is to reduce the amount of hardware in the factory through “function integration”, for example, one IPC can realize equipment control, data acquisition and cloud communication at the same time.

Anti-Harsh Environment Design: Adopting fanless cooling and full metal body, it supports IP65 dustproof and waterproof rating, and some models can work in -25℃~60℃ wide temperature environment.

Flexible Expansion Capability: Provides PCIe slot, M.2 interface, and supports expansion of wireless modules (such as 5G, Wi-Fi 6), GPU acceleration card or motion control card to meet the needs of machine vision, robot control, and so on.

Diversified installation methods: support DIN rail mounting (suitable for control cabinets), VESA wall-mounting (suitable for operating consoles) or rack-mounting (data center scenarios).

Powerful processing capability: Equipped with Intel Core/i7 or AMD Rare Dragon processor, it can run Python, C++ and other high-level languages, and supports the deployment of deep learning models (such as YOLO target detection).

IT/OT convergence capability: Native support for industrial protocols such as OPC UA, MQTT, etc., which can be directly interfaced with the ERP system to realize real-time uploading and analysis of production data.

Convenient remote management: Remote monitoring and firmware upgrading can be realized through tools such as TeamViewer and VNC, reducing maintenance costs.

High initial investment: the cost of high-end IPC can reach tens of thousands of dollars, far more than small PLC systems.

High security requirements: firewalls, intrusion detection systems (IDS) and industrial-grade antivirus software need to be deployed to deal with ransomware (e.g. NotPetya) threats.

Environmental adaptation is configuration-dependent: some non-ruggedized IPCs require additional protection in extreme vibration or high dust environments.

PLC: Depends on real-time operating system (RTOS), adopts cyclic scanning mechanism to ensure the time certainty of each instruction cycle, which is suitable for millisecond precision control tasks (e.g. mold closing timing of injection molding machine).

IPC: running a general-purpose operating system, it needs to realize hard real-time functions through real-time extension modules (such as RTX real-time kernel), and is more suitable for scenarios with slightly lower real-time requirements but requiring multi-tasking (such as intelligent warehouse scheduling).

PLC: Ladder Logic (Ladder Logic), Function Block Diagram (FBD) is the main, most of the development tools for manufacturers of customized software (such as Siemens TIA Portal), the ecology is closed, but the stability is strong.

IPC: Supports C/C++, Python, .NET and other general-purpose languages, and can reuse open source libraries (such as OpenCV vision library) and industrial software (such as MATLAB Industrial), with high development efficiency and strong functionality expansion.

Small Systems: PLCs offer significant cost advantages. For example, for a small project controlling 10 digital inputs/outputs, a PLC solution can be as low as 1/3 the cost of an IPC.

Complex Systems: IPCs have a superior total cost of ownership (TCO). When vision inspection, data storage, and cloud-based communications need to be integrated, IPC reduces the combined costs of hardware purchase, cabling, and maintenance.

PLC: Traditional architectures are less exposed to cyberattacks, but as the Industrial Internet of Things (IIoT) becomes more prevalent, Ethernet-enabled PLCs need to deploy additional firewalls.

Typical case: Stuxnet virus (2010) attacked Iranian nuclear facilities through PLC vulnerability, highlighting cyber security risks.

IPC: Relying on software protection system, system patches and virus databases need to be updated regularly. However, industrial-grade IPCs usually have built-in TPM 2.0 chips, support hardware-level data encryption, and comply with ISO/IEC 27001 information security standards.

Control complexity

Simple Logic Control: If the project only involves simple logic of “sensor trigger - actuator response” (e.g., automatic door opening and closing), PLC is sufficient to meet the requirements and the development cycle is short.

Complex Algorithmic Applications: For features such as vision-guided assembly, equipment health prediction, etc., choose an IPC to support machine learning model deployment.

Environmental Harshness

Extreme physical environments: high temperature (e.g., steel workshop), high vibration (e.g., mining machinery) scenarios prioritize PLCs, whose hardware durability has been verified by long-term industrial validation.

Mild industrial environments: In scenarios such as electronics manufacturing shops and clean food factories, IPC's fanless design and protection ratings already meet the needs.

System Expandability

Fixed Functional Requirements: For example, the modular expansion of PLC is more cost-effective for traditional production line modification (only the control part is upgraded).

Future upgrade planning: If you plan to transform to a smart factory (e.g., access to IoT platform), IPC's IT/OT convergence capability can avoid repeated investment.

PLCs and industrial computers represent the “past” and “future” of industrial automation: the former is the cornerstone of mature and reliable control, while the latter is the core engine that leads intelligence. Enterprises need to jump out of the “either/or” thinking and make comprehensive decisions from the following dimensions when selecting models:

Short-term project: prioritize the cost and stability of PLC, applicable to limited budget, clear function of the scene.

Medium- to long-term planning: invest in IPC to accommodate digital transformation needs, especially projects involving big data, AI and cloud integration.

Complex systems: adopt “PLC+IPC” hybrid architecture to achieve synergistic optimization between control and intelligence layers.

As a professional manufacturer in the field of industrial computers, IPCTech provides a full range of ruggedized industrial computers, supporting a variety of form factors from 15-inch touch panels to rack-mounted servers, and adapting to scenarios such as PLC integration, machine vision, edge computing, and so on. For customized automation solutions, please contact us for a free technical consultation to help your factory move towards an efficient and intelligent future.

What is a PLC?

PLC (Programmable Logic Controller) is a special computer designed for industrial environments, and its core function is to realize automated control of mechanical equipment through real-time logic operations. The hardware is modular and consists of a central processing unit (CPU), input/output (I/O) modules, power supply modules, and storage units. Unlike general-purpose computers, the PLC's operating system is a real-time operating system (RTOS), which ensures microsecond command execution accuracy and allows it to respond in real time to sensor signals (e.g., temperature, pressure) and control actuators (e.g., motors, valves).

Hardware types and typical applications

Miniature PLC: Compact size (such as the size of the palm of your hand), integrated with basic I/O interfaces, suitable for single device control, such as start-stop logic control of small packaging machines.

Modular PLC: Supports flexible expansion of I/O modules (e.g. digital, analog, communication modules), suitable for complex production lines, e.g. collaborative control of robotic arms in automotive assembly workshops.

Rackmount PLC: With strong processing power and expansion capacity, it is commonly used in large industrial systems, such as centralized control systems (DCS) in the petrochemical field.

Advantages of PLCs

High reliability: fanless design, wide temperature operation (-40℃~70℃) and vibration-resistant structure allow stable operation in harsh environments such as dust and oil.

High real-time: based on scanning cycle mechanism, it ensures deterministic execution of control instructions, suitable for time-sensitive scenarios (e.g. high-speed filling production line).

Low programming threshold: supports graphical programming languages such as Ladder Logic, making it easy for field engineers to get started quickly.

Limitations of PLCs

Limited processing power: only supports simple logic operations, difficult to perform complex tasks such as machine learning and big data analysis.

Single-function: focused on industrial control, integration with IT systems (e.g. ERP, MES) requires additional gateway devices.

High cost of complex systems: when a large number of I/O modules or communication protocol conversions are required, the hardware cost increases exponentially.

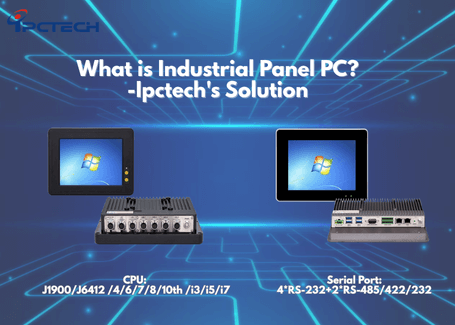

What is an Industrial PC?

An Industrial PC is an enhanced computer based on the general-purpose PC architecture, designed for industrial scenarios, running Windows, Linux, and other major operating systems. With the development of semiconductor technology, IPC can not only fulfill the control tasks of traditional PLC, but also carry multiple workloads such as HMI, edge computing, AI vision detection, etc. by integrating GPU (Graphics Processor), TPU (Tensor Processor) and NVMe SSD (High Speed Solid State Disk), and the core value is to reduce the number of hardware in the factory through “function integration”. Its core value is to reduce the amount of hardware in the factory through “function integration”, for example, one IPC can realize equipment control, data acquisition and cloud communication at the same time.

Hardware Features and Deployment Methods

Anti-Harsh Environment Design: Adopting fanless cooling and full metal body, it supports IP65 dustproof and waterproof rating, and some models can work in -25℃~60℃ wide temperature environment.

Flexible Expansion Capability: Provides PCIe slot, M.2 interface, and supports expansion of wireless modules (such as 5G, Wi-Fi 6), GPU acceleration card or motion control card to meet the needs of machine vision, robot control, and so on.

Diversified installation methods: support DIN rail mounting (suitable for control cabinets), VESA wall-mounting (suitable for operating consoles) or rack-mounting (data center scenarios).

Advantages of Industrial Computers

Powerful processing capability: Equipped with Intel Core/i7 or AMD Rare Dragon processor, it can run Python, C++ and other high-level languages, and supports the deployment of deep learning models (such as YOLO target detection).

IT/OT convergence capability: Native support for industrial protocols such as OPC UA, MQTT, etc., which can be directly interfaced with the ERP system to realize real-time uploading and analysis of production data.

Convenient remote management: Remote monitoring and firmware upgrading can be realized through tools such as TeamViewer and VNC, reducing maintenance costs.

Limitations of Industrial Computers

High initial investment: the cost of high-end IPC can reach tens of thousands of dollars, far more than small PLC systems.

High security requirements: firewalls, intrusion detection systems (IDS) and industrial-grade antivirus software need to be deployed to deal with ransomware (e.g. NotPetya) threats.

Environmental adaptation is configuration-dependent: some non-ruggedized IPCs require additional protection in extreme vibration or high dust environments.

Difference Between Industrial PC VS PLC?

Operating System and Real Time

PLC: Depends on real-time operating system (RTOS), adopts cyclic scanning mechanism to ensure the time certainty of each instruction cycle, which is suitable for millisecond precision control tasks (e.g. mold closing timing of injection molding machine).

IPC: running a general-purpose operating system, it needs to realize hard real-time functions through real-time extension modules (such as RTX real-time kernel), and is more suitable for scenarios with slightly lower real-time requirements but requiring multi-tasking (such as intelligent warehouse scheduling).

Programming language and development ecology

PLC: Ladder Logic (Ladder Logic), Function Block Diagram (FBD) is the main, most of the development tools for manufacturers of customized software (such as Siemens TIA Portal), the ecology is closed, but the stability is strong.

IPC: Supports C/C++, Python, .NET and other general-purpose languages, and can reuse open source libraries (such as OpenCV vision library) and industrial software (such as MATLAB Industrial), with high development efficiency and strong functionality expansion.

Cost Modeling

Small Systems: PLCs offer significant cost advantages. For example, for a small project controlling 10 digital inputs/outputs, a PLC solution can be as low as 1/3 the cost of an IPC.

Complex Systems: IPCs have a superior total cost of ownership (TCO). When vision inspection, data storage, and cloud-based communications need to be integrated, IPC reduces the combined costs of hardware purchase, cabling, and maintenance.

Security and Reliability

PLC: Traditional architectures are less exposed to cyberattacks, but as the Industrial Internet of Things (IIoT) becomes more prevalent, Ethernet-enabled PLCs need to deploy additional firewalls.

Typical case: Stuxnet virus (2010) attacked Iranian nuclear facilities through PLC vulnerability, highlighting cyber security risks.

IPC: Relying on software protection system, system patches and virus databases need to be updated regularly. However, industrial-grade IPCs usually have built-in TPM 2.0 chips, support hardware-level data encryption, and comply with ISO/IEC 27001 information security standards.

Hardware Architecture and Scalability

|

Scenario Matrix

| Application Type | PLC Priority Scenario | IPC Priority Scenario |

| Equipment Control | Single machine tool, conveyor start/stop | Motion planning for collaborative robots, AGV navigation |

| Process Monitoring | Closed-loop level/temperature control in chemical plants | Real-time analysis of semiconductor cleanroom environmental data |

| Data Management | Simple production counting | MES system integration, historical data storage and traceability |

| Edge Computing | Not applicable | AI defect detection, predictive maintenance (e.g. motor failure warning) |

Industrial Automation Selection Decision Guide

Three Elements of Requirements Analysis

Control complexity

Simple Logic Control: If the project only involves simple logic of “sensor trigger - actuator response” (e.g., automatic door opening and closing), PLC is sufficient to meet the requirements and the development cycle is short.

Complex Algorithmic Applications: For features such as vision-guided assembly, equipment health prediction, etc., choose an IPC to support machine learning model deployment.

Environmental Harshness

Extreme physical environments: high temperature (e.g., steel workshop), high vibration (e.g., mining machinery) scenarios prioritize PLCs, whose hardware durability has been verified by long-term industrial validation.

Mild industrial environments: In scenarios such as electronics manufacturing shops and clean food factories, IPC's fanless design and protection ratings already meet the needs.

System Expandability

Fixed Functional Requirements: For example, the modular expansion of PLC is more cost-effective for traditional production line modification (only the control part is upgraded).

Future upgrade planning: If you plan to transform to a smart factory (e.g., access to IoT platform), IPC's IT/OT convergence capability can avoid repeated investment.

Conclusion

PLCs and industrial computers represent the “past” and “future” of industrial automation: the former is the cornerstone of mature and reliable control, while the latter is the core engine that leads intelligence. Enterprises need to jump out of the “either/or” thinking and make comprehensive decisions from the following dimensions when selecting models:

Short-term project: prioritize the cost and stability of PLC, applicable to limited budget, clear function of the scene.

Medium- to long-term planning: invest in IPC to accommodate digital transformation needs, especially projects involving big data, AI and cloud integration.

Complex systems: adopt “PLC+IPC” hybrid architecture to achieve synergistic optimization between control and intelligence layers.

Why Choose IPCTech?

As a professional manufacturer in the field of industrial computers, IPCTech provides a full range of ruggedized industrial computers, supporting a variety of form factors from 15-inch touch panels to rack-mounted servers, and adapting to scenarios such as PLC integration, machine vision, edge computing, and so on. For customized automation solutions, please contact us for a free technical consultation to help your factory move towards an efficient and intelligent future.

Recommended