Fanless Mini PC for Efficient Industrial Use

2025-07-24

In the modern industrial sector, computing faces numerous challenging issues. Factory workshops, energy stations, and other industrial settings often have limited space, making it difficult for traditional industrial control equipment to adapt; meanwhile, these environments are filled with dust, vibration, and temperature fluctuations, making ordinary computers more prone to failure. Moreover, high-energy devices are gradually being phased out of the market.

In this context, fanless mini industrial computers have emerged as an ideal solution to these challenges. Its unique fanless design fundamentally transforms the mode of industrial computing, not only adapting to harsh industrial environments but also significantly enhancing the efficiency of industrial production.

The key reason why fanless mini industrial control computers stand out in the industrial sector lies in their numerous characteristics, which perfectly meet the needs of industrial scenarios.

Firstly, the absence of moving parts is one of its major highlights. Traditional industrial computer fans and other movable components are prone to failure due to dust accumulation and mechanical wear, whereas fanless mini industrial computers lack these components, significantly reducing the likelihood of failures and maintenance frequency and costs.

Next, its compact size makes it suitable for industrial environments with limited space. In some precision instrument production lines or small control cabinets, traditional industrial computers cannot be installed at all, while fanless mini industrial computers are compact and can be easily integrated, saving a significant amount of space. For example, in a small control cabinet in the electronics component assembly workshop, a fanless mini industrial computer, which is only one-fifth the size of traditional equipment, can perfectly perform control tasks.

Moreover, durability is at the core of its ability to adapt to industrial harsh environments. It boasts excellent dust protection, vibration resistance, and extreme temperature stability, capable of operating stably in environments with high dust concentrations, continuous machine vibration, and temperature fluctuations ranging from -40°C to 70°C in mining sites and steel mills. There is data showing that fanless mini industrial computers can last 3 to 4 times longer than traditional industrial computers in equally harsh environments.

Finally, the characteristic of silent operation plays a significant role in noise-sensitive industrial environments. In precision instrument testing workshops, medical equipment production workshops, and other locations, excessive noise can affect detection accuracy and workers' working conditions. Fanless mini industrial computers operate with almost no sound, providing these areas with a quiet computing environment.

A high-performance industrial-grade fanless mini industrial control computer can excel in industrial applications thanks to its powerful core features.

ipctech's high-performance industrial-grade fanless mini industrial control computer is equipped with embedded processors from Intel, AMD, and other industrial-grade devices tailored for deep customization in industrial scenarios. These processors are specially optimized to demonstrate outstanding multitasking concurrent processing performance while ensuring low-power operation. In line with the nearly stringent requirements for computational continuity and stability in industrial production, we ensure that the production rhythm proceeds in an orderly manner. Whether it's real-time data collection and analysis, complex logic control algorithms running, or efficient loading of industrial software, stable output can be maintained. Even under continuous full-load operation for 72 hours, performance fluctuations can be controlled within 5%, meeting the stringent requirements for computational continuity in industrial production.

ipctech fully considers the complex and diverse needs of industrial sites, equipping fanless mini industrial control computers with a wide range of industrial-grade interfaces and expansion slots. Multiple high-speed USB ports can quickly connect various peripherals, such as data acquisition sensors and portable handheld terminals; gigabit Ethernet interfaces ensure high-speed and stable data transmission in industrial networks; RS-232/485 serial ports enable seamless integration with traditional industrial equipment. At the same time, PCIe, GPIO, and other expansion interfaces reserve ample space for expanding device functionality. In the automation production line renovation project for smart factories, IPCTech fanless mini industrial computers can easily integrate multi-axis motion controllers, visual inspection cameras, and PLC programmable logic controllers and industrial robots to meet full-scene industrial application needs.

From the outset, ipctech made adapting to extreme environments a key metric for fanless mini industrial computers. Adopting a fully sealed fanless design, it prevents dust, debris, and other impurities from entering the interior, and is paired with a high-conductivity alloy casing to construct an efficient passive cooling system. It can operate stably over a wide temperature range from -40°C in extremely cold storage environments to 70°C in industrial kilns. At the same time, its protection rating exceeds IP65, effectively preventing dust and water damage. It can operate stably with excellent vibration resistance and electromagnetic interference in dusty mining workshops, humid food processing workshops, or vibrating construction machinery sites, ensuring that industrial production processes are not affected by equipment failures.

ipctech fanless mini industrial-grade solid-state drives (SSDs) come standard with read and write speeds exceeding 500 MB/s, offering inherent impact and vibration resistance compared to traditional mechanical hard drives, thereby avoiding data loss risks from industrial site vibrations and collisions. Moreover, the product supports RAID redundancy storage technology, enabling real-time backups of critical production data. Even if a storage unit fails, the data remains intact. In terms of data encryption, ipctech protects industrial production data with advanced algorithms, meeting the high demands for data integrity and security in key industry scenarios such as finance and energy, ensuring the safety of enterprise core data assets.

ipctech is dedicated to providing users with a convenient and efficient user experience, and its fanless mini industrial computers are deeply compatible with mainstream operating systems such as Windows and Linux, whether mature and stable versions or open-source and flexible Linux systems. At the same time, for industrial scenarios with stringent requirements for real-time performance. In practical applications, it can smoothly run industrial management software such as manufacturing execution systems (MES), data acquisition and monitoring control systems (SCADA), as well as cutting-edge professional programs like machine vision inspection and edge computing. The system startup time is as short as 15 seconds, significantly enhancing equipment response speed; it also supports breakpoint persistence, allowing for quick recovery of industrial processes in case of sudden interruptions, thereby reducing production downtime and ensuring continuity.

Using a low-power architecture design combined with a fully solid-state structure free from mechanical wear, the average fault-free operation time exceeds 100,000 hours, significantly reducing equipment replacement frequency and energy costs, aligning with the trend towards green and low-carbon development in the industrial sector.

Fanless mini industrial computers play a crucial role in multiple industrial sectors due to their outstanding performance, providing robust support for efficient operations across various industries.

In manufacturing, it seamlessly integrates with IoT sensors to collect real-time temperature, pressure, speed, and other data on the production line. By analyzing the production line monitoring system, production anomalies are promptly identified and adjusted. At the same time, in automated systems, it serves as the control core, precisely controlling the operation of robots, conveyor belts, and other equipment to enhance production efficiency and product quality.

The logistics and warehousing industries have also greatly benefited from fanless mini industrial computers. In inventory management, it can quickly process barcode scan information, update inventory data in real time, and ensure the accuracy of inventory. In terms of conveyor belt control, it can intelligently adjust the speed of the conveyor belt based on information such as the quantity and weight of the goods, thereby reducing energy waste.

The energy and utility sectors utilize fanless mini industrial computers for remote monitoring. In the power grid, it can monitor substation equipment operations and power loads in real time to warn of failures; along oil and gas pipelines, it can collect pressure and flow information to ensure safe operation; in renewable energy systems like solar and wind, it can monitor and optimize power generation equipment to improve energy efficiency.

In the transportation industry, fanless mini industrial computers are also widely used. In on-board computing, it is used for fleet management to real-time obtain vehicle position, speed, fuel consumption, and optimize scheduling; in railway systems, it can monitor the operation of track equipment and signaling systems; and in maritime operations, it can assist with ship navigation and equipment monitoring.

In the healthcare industry, fanless mini industrial computers are used for controlling medical devices and laboratory automation. Its operation is stable, ensuring the precise operation of medical devices such as CT machines and MRI machines; in the laboratory, it can control automated testing equipment to enhance detection efficiency and accuracy. Moreover, its casing is made of antibacterial material, meeting the hygiene requirements of medical environments.

When choosing an industrial fanless mini industrial control computer, multiple factors need to be considered to ensure it perfectly meets specific industrial requirements.

Environmental requirements are the top consideration. Different industrial environments have varying temperature adaptation ranges and requirements for dust and water resistance. For example, in a food processing plant, the environment is relatively clean but the temperature may be high and humid, requiring equipment with IP65 dust and water resistance; whereas in a mining facility, fanless mini-controllers with IP67 protection should be chosen.

Performance requirements should also not be overlooked and should be matched according to specific industrial tasks with the appropriate CPU and memory. For tasks such as industrial IoT gateways that require real-time processing of large amounts of data and complex machine vision detection, high-performance CPUs and over 8GB of memory are needed.

The connection requirements must ensure compatibility with existing industrial hardware. Need to clarify the types of interfaces and communication protocols for existing industrial sensors, machinery, and networks, and choose a fanless mini industrial computer equipped with the appropriate interfaces and supporting the corresponding protocols. If most of the existing sensors in the factory have RS-485 interfaces, then devices with RS-485 serial ports must be selected.

In terms of reliability and warranty, it's important to ensure that the equipment meets industrial-grade certifications such as CE and FCC certifications, and ATEX certification is also required for devices used in some hazardous areas. These certifications are crucial for ensuring equipment quality and reliability. At the same time, good warranty service is crucial, and it's best to choose products that offer more than 3 years of warranty to reduce the risk of later use.

To ensure that fanless mini industrial computers continue to perform stably in industrial settings, it is essential to do proper maintenance and understand their lifespan.

In terms of maintenance, while fanless mini industrial control computers require lower maintenance needs, several key points still need to be noted. Regularly clean the equipment surface with compressed air to prevent dust accumulation from affecting heat dissipation; avoid severe impacts and excessive vibrations; regularly check if the interface connections are loose to ensure normal communication.

Regarding lifespan, fanless mini industrial computers have a longer lifespan compared to traditional industrial computers. Traditional industrial computers have an average lifespan of 3 to 5 years due to losses from fans and other components, whereas fanless mini industrial computers can last up to 7 to 10 years under normal use and maintenance. This means that businesses can reduce the frequency of equipment replacements and lower long-term costs.

On frequently asked questions about troubleshooting, it's important to avoid overheating and update the software promptly. Fanless mini industrial computers rely on passive cooling to ensure good ventilation around them and avoid being blocked by other devices; meanwhile, they regularly update their operating systems and drivers to fix vulnerabilities, enhance performance, and improve security. If equipment operation slows down, it may be due to poor heat dissipation or software updates. Addressing these issues promptly can help the equipment quickly return to normal.

Yes, fanless mini industrial control computers come equipped with industrial-grade CPUs and ample memory, meeting the demands of most demanding industrial tasks such as real-time data processing and complex control algorithms. As technology advances, its performance continues to improve, making it fully capable of meeting various challenges in the industrial sector.

The fanless mini industrial computer features a passive cooling design, dissipating heat from within the device to the surrounding environment through large areas of heat sinks and efficient heat-conducting materials. At the same time, its casing is typically made of high-conductivity metal materials that can quickly dissipate heat, ensuring stable operation in high-temperature environments.

Sure. The fanless mini industrial control computer has excellent scalability and can be customized with interface types and quantities, storage capacity, reinforcement levels, and more according to the needs of different industrial scenarios, to suit unique industrial settings.

Under normal use and maintenance, fanless mini industrial computers typically last 7 to 10 years in industrial environments, which is significantly longer than the 3-5 years of traditional industrial computers.

The initial procurement cost of fanless mini industrial computers may be slightly higher than that of traditional industrial computers, but in the long term, they have lower maintenance costs, less energy consumption, longer lifespan, and overall lower costs. Over a 10-year cycle, the total cost of fanless mini industrial computers is approximately 60% to 70% that of traditional industrial computers.

In summary, fanless mini industrial computers have become an ideal choice for industrial computing due to their durability, high efficiency, and compact size. It can adapt to various harsh industrial environments, reduce failure and maintenance costs, enhance production efficiency, and bring significant economic benefits to different industrial sectors.

In today's competitive industrial market, adopting fanless mini industrial computers is an important measure for businesses to enhance their competitiveness. It not only meets the current demands of industrial production but also adapts to the future trends of industrial intelligence and automation. Therefore, when choosing industrial computing equipment, companies should fully consider the advantages of fanless mini-control computers, selecting appropriate products based on their industrial scenarios and needs to drive efficient and stable industrial production toward a smarter and more sustainable future.

In this context, fanless mini industrial computers have emerged as an ideal solution to these challenges. Its unique fanless design fundamentally transforms the mode of industrial computing, not only adapting to harsh industrial environments but also significantly enhancing the efficiency of industrial production.

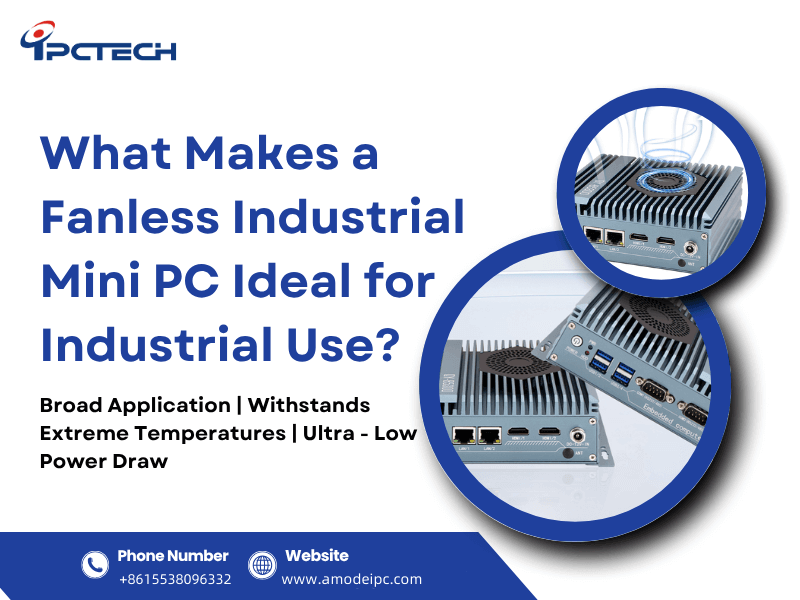

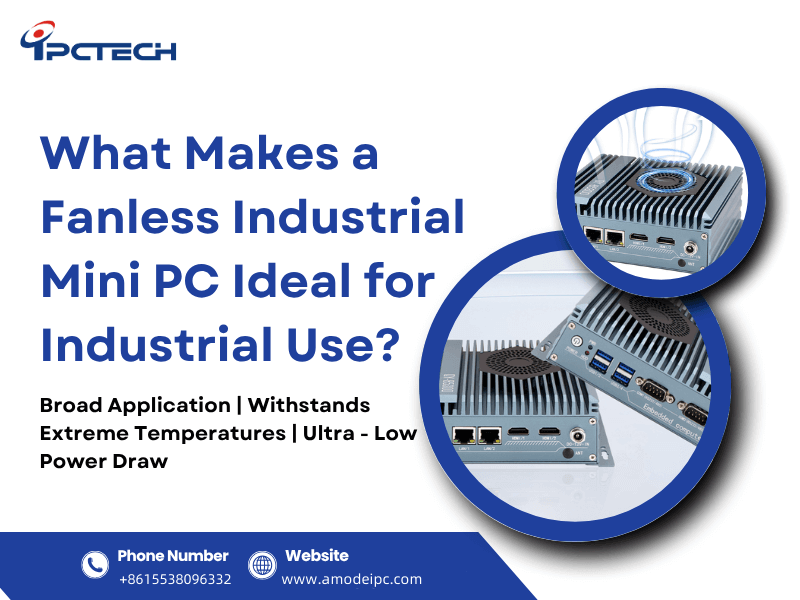

What Makes a Fanless Industrial Mini PC Ideal for Industrial Use?

The key reason why fanless mini industrial control computers stand out in the industrial sector lies in their numerous characteristics, which perfectly meet the needs of industrial scenarios.

Firstly, the absence of moving parts is one of its major highlights. Traditional industrial computer fans and other movable components are prone to failure due to dust accumulation and mechanical wear, whereas fanless mini industrial computers lack these components, significantly reducing the likelihood of failures and maintenance frequency and costs.

Next, its compact size makes it suitable for industrial environments with limited space. In some precision instrument production lines or small control cabinets, traditional industrial computers cannot be installed at all, while fanless mini industrial computers are compact and can be easily integrated, saving a significant amount of space. For example, in a small control cabinet in the electronics component assembly workshop, a fanless mini industrial computer, which is only one-fifth the size of traditional equipment, can perfectly perform control tasks.

Moreover, durability is at the core of its ability to adapt to industrial harsh environments. It boasts excellent dust protection, vibration resistance, and extreme temperature stability, capable of operating stably in environments with high dust concentrations, continuous machine vibration, and temperature fluctuations ranging from -40°C to 70°C in mining sites and steel mills. There is data showing that fanless mini industrial computers can last 3 to 4 times longer than traditional industrial computers in equally harsh environments.

Finally, the characteristic of silent operation plays a significant role in noise-sensitive industrial environments. In precision instrument testing workshops, medical equipment production workshops, and other locations, excessive noise can affect detection accuracy and workers' working conditions. Fanless mini industrial computers operate with almost no sound, providing these areas with a quiet computing environment.

Core Features of High-Performance Fanless Mini PCs for Industrial Applications

A high-performance industrial-grade fanless mini industrial control computer can excel in industrial applications thanks to its powerful core features.

Strong and stable processing capacity

ipctech's high-performance industrial-grade fanless mini industrial control computer is equipped with embedded processors from Intel, AMD, and other industrial-grade devices tailored for deep customization in industrial scenarios. These processors are specially optimized to demonstrate outstanding multitasking concurrent processing performance while ensuring low-power operation. In line with the nearly stringent requirements for computational continuity and stability in industrial production, we ensure that the production rhythm proceeds in an orderly manner. Whether it's real-time data collection and analysis, complex logic control algorithms running, or efficient loading of industrial software, stable output can be maintained. Even under continuous full-load operation for 72 hours, performance fluctuations can be controlled within 5%, meeting the stringent requirements for computational continuity in industrial production.

Flexible and diverse expansion capabilities

ipctech fully considers the complex and diverse needs of industrial sites, equipping fanless mini industrial control computers with a wide range of industrial-grade interfaces and expansion slots. Multiple high-speed USB ports can quickly connect various peripherals, such as data acquisition sensors and portable handheld terminals; gigabit Ethernet interfaces ensure high-speed and stable data transmission in industrial networks; RS-232/485 serial ports enable seamless integration with traditional industrial equipment. At the same time, PCIe, GPIO, and other expansion interfaces reserve ample space for expanding device functionality. In the automation production line renovation project for smart factories, IPCTech fanless mini industrial computers can easily integrate multi-axis motion controllers, visual inspection cameras, and PLC programmable logic controllers and industrial robots to meet full-scene industrial application needs.

all-weather environmental adaptability

From the outset, ipctech made adapting to extreme environments a key metric for fanless mini industrial computers. Adopting a fully sealed fanless design, it prevents dust, debris, and other impurities from entering the interior, and is paired with a high-conductivity alloy casing to construct an efficient passive cooling system. It can operate stably over a wide temperature range from -40°C in extremely cold storage environments to 70°C in industrial kilns. At the same time, its protection rating exceeds IP65, effectively preventing dust and water damage. It can operate stably with excellent vibration resistance and electromagnetic interference in dusty mining workshops, humid food processing workshops, or vibrating construction machinery sites, ensuring that industrial production processes are not affected by equipment failures.

Secure and reliable storage solutions

ipctech fanless mini industrial-grade solid-state drives (SSDs) come standard with read and write speeds exceeding 500 MB/s, offering inherent impact and vibration resistance compared to traditional mechanical hard drives, thereby avoiding data loss risks from industrial site vibrations and collisions. Moreover, the product supports RAID redundancy storage technology, enabling real-time backups of critical production data. Even if a storage unit fails, the data remains intact. In terms of data encryption, ipctech protects industrial production data with advanced algorithms, meeting the high demands for data integrity and security in key industry scenarios such as finance and energy, ensuring the safety of enterprise core data assets.

Full system compatibility

ipctech is dedicated to providing users with a convenient and efficient user experience, and its fanless mini industrial computers are deeply compatible with mainstream operating systems such as Windows and Linux, whether mature and stable versions or open-source and flexible Linux systems. At the same time, for industrial scenarios with stringent requirements for real-time performance. In practical applications, it can smoothly run industrial management software such as manufacturing execution systems (MES), data acquisition and monitoring control systems (SCADA), as well as cutting-edge professional programs like machine vision inspection and edge computing. The system startup time is as short as 15 seconds, significantly enhancing equipment response speed; it also supports breakpoint persistence, allowing for quick recovery of industrial processes in case of sudden interruptions, thereby reducing production downtime and ensuring continuity.

Low-efficiency long-lasting energy performance

Using a low-power architecture design combined with a fully solid-state structure free from mechanical wear, the average fault-free operation time exceeds 100,000 hours, significantly reducing equipment replacement frequency and energy costs, aligning with the trend towards green and low-carbon development in the industrial sector.

Key Industrial Sectors Benefiting from Fanless Industrial Fanless PC

Fanless mini industrial computers play a crucial role in multiple industrial sectors due to their outstanding performance, providing robust support for efficient operations across various industries.

In manufacturing, it seamlessly integrates with IoT sensors to collect real-time temperature, pressure, speed, and other data on the production line. By analyzing the production line monitoring system, production anomalies are promptly identified and adjusted. At the same time, in automated systems, it serves as the control core, precisely controlling the operation of robots, conveyor belts, and other equipment to enhance production efficiency and product quality.

The logistics and warehousing industries have also greatly benefited from fanless mini industrial computers. In inventory management, it can quickly process barcode scan information, update inventory data in real time, and ensure the accuracy of inventory. In terms of conveyor belt control, it can intelligently adjust the speed of the conveyor belt based on information such as the quantity and weight of the goods, thereby reducing energy waste.

The energy and utility sectors utilize fanless mini industrial computers for remote monitoring. In the power grid, it can monitor substation equipment operations and power loads in real time to warn of failures; along oil and gas pipelines, it can collect pressure and flow information to ensure safe operation; in renewable energy systems like solar and wind, it can monitor and optimize power generation equipment to improve energy efficiency.

In the transportation industry, fanless mini industrial computers are also widely used. In on-board computing, it is used for fleet management to real-time obtain vehicle position, speed, fuel consumption, and optimize scheduling; in railway systems, it can monitor the operation of track equipment and signaling systems; and in maritime operations, it can assist with ship navigation and equipment monitoring.

In the healthcare industry, fanless mini industrial computers are used for controlling medical devices and laboratory automation. Its operation is stable, ensuring the precise operation of medical devices such as CT machines and MRI machines; in the laboratory, it can control automated testing equipment to enhance detection efficiency and accuracy. Moreover, its casing is made of antibacterial material, meeting the hygiene requirements of medical environments.

Factors to Consider When Choosing a Fanless Mini Industrial Computer for Industrial Needs

When choosing an industrial fanless mini industrial control computer, multiple factors need to be considered to ensure it perfectly meets specific industrial requirements.

Environmental requirements are the top consideration. Different industrial environments have varying temperature adaptation ranges and requirements for dust and water resistance. For example, in a food processing plant, the environment is relatively clean but the temperature may be high and humid, requiring equipment with IP65 dust and water resistance; whereas in a mining facility, fanless mini-controllers with IP67 protection should be chosen.

Performance requirements should also not be overlooked and should be matched according to specific industrial tasks with the appropriate CPU and memory. For tasks such as industrial IoT gateways that require real-time processing of large amounts of data and complex machine vision detection, high-performance CPUs and over 8GB of memory are needed.

The connection requirements must ensure compatibility with existing industrial hardware. Need to clarify the types of interfaces and communication protocols for existing industrial sensors, machinery, and networks, and choose a fanless mini industrial computer equipped with the appropriate interfaces and supporting the corresponding protocols. If most of the existing sensors in the factory have RS-485 interfaces, then devices with RS-485 serial ports must be selected.

In terms of reliability and warranty, it's important to ensure that the equipment meets industrial-grade certifications such as CE and FCC certifications, and ATEX certification is also required for devices used in some hazardous areas. These certifications are crucial for ensuring equipment quality and reliability. At the same time, good warranty service is crucial, and it's best to choose products that offer more than 3 years of warranty to reduce the risk of later use.

Maintenance and Longevity: Ensuring Sustained Performance of Fanless Mini PCs

To ensure that fanless mini industrial computers continue to perform stably in industrial settings, it is essential to do proper maintenance and understand their lifespan.

In terms of maintenance, while fanless mini industrial control computers require lower maintenance needs, several key points still need to be noted. Regularly clean the equipment surface with compressed air to prevent dust accumulation from affecting heat dissipation; avoid severe impacts and excessive vibrations; regularly check if the interface connections are loose to ensure normal communication.

Regarding lifespan, fanless mini industrial computers have a longer lifespan compared to traditional industrial computers. Traditional industrial computers have an average lifespan of 3 to 5 years due to losses from fans and other components, whereas fanless mini industrial computers can last up to 7 to 10 years under normal use and maintenance. This means that businesses can reduce the frequency of equipment replacements and lower long-term costs.

On frequently asked questions about troubleshooting, it's important to avoid overheating and update the software promptly. Fanless mini industrial computers rely on passive cooling to ensure good ventilation around them and avoid being blocked by other devices; meanwhile, they regularly update their operating systems and drivers to fix vulnerabilities, enhance performance, and improve security. If equipment operation slows down, it may be due to poor heat dissipation or software updates. Addressing these issues promptly can help the equipment quickly return to normal.

FAQ

Is the performance of fanless mini industrial computers sufficient to handle heavy industrial tasks?

Yes, fanless mini industrial control computers come equipped with industrial-grade CPUs and ample memory, meeting the demands of most demanding industrial tasks such as real-time data processing and complex control algorithms. As technology advances, its performance continues to improve, making it fully capable of meeting various challenges in the industrial sector.

How does a fanless mini industrial computer dissipate heat in high-temperature environments?

The fanless mini industrial computer features a passive cooling design, dissipating heat from within the device to the surrounding environment through large areas of heat sinks and efficient heat-conducting materials. At the same time, its casing is typically made of high-conductivity metal materials that can quickly dissipate heat, ensuring stable operation in high-temperature environments.

Can fanless mini industrial control computers be customized for unique industrial settings?

Sure. The fanless mini industrial control computer has excellent scalability and can be customized with interface types and quantities, storage capacity, reinforcement levels, and more according to the needs of different industrial scenarios, to suit unique industrial settings.

What is the typical lifespan of a fanless mini industrial control computer in industrial use?

Under normal use and maintenance, fanless mini industrial computers typically last 7 to 10 years in industrial environments, which is significantly longer than the 3-5 years of traditional industrial computers.

How does a fanless mini industrial computer compare in cost to a traditional industrial computer?

The initial procurement cost of fanless mini industrial computers may be slightly higher than that of traditional industrial computers, but in the long term, they have lower maintenance costs, less energy consumption, longer lifespan, and overall lower costs. Over a 10-year cycle, the total cost of fanless mini industrial computers is approximately 60% to 70% that of traditional industrial computers.

Why Fanless Mini PCs Are the Future of Efficient Industrial Computing?

In summary, fanless mini industrial computers have become an ideal choice for industrial computing due to their durability, high efficiency, and compact size. It can adapt to various harsh industrial environments, reduce failure and maintenance costs, enhance production efficiency, and bring significant economic benefits to different industrial sectors.

In today's competitive industrial market, adopting fanless mini industrial computers is an important measure for businesses to enhance their competitiveness. It not only meets the current demands of industrial production but also adapts to the future trends of industrial intelligence and automation. Therefore, when choosing industrial computing equipment, companies should fully consider the advantages of fanless mini-control computers, selecting appropriate products based on their industrial scenarios and needs to drive efficient and stable industrial production toward a smarter and more sustainable future.

Recommended