Why Fanless Mini PCs are Ideal for Industrial Applications

2025-08-31

Driven by the wave of Industry 4.0, industrial automation and smart factory development are accelerating, with equipment miniaturization, high efficiency, and low power consumption becoming core industry demands.Traditional industrial control equipment (such as large servers and legacy industrial PCs) commonly suffer from bulky sizes, high energy consumption, complex maintenance, and poor adaptability. These limitations make them ill-suited for modern industrial scenarios demanding compact installation spaces, long-term stable operation, and low-cost maintenance. In contrast, industrial-grade Mini PCs, with their compact dimensions, high stability, and low power consumption, are increasingly becoming a high-demand solution in the industrial sector—the ideal choice for addressing the pain points of industrial applications.

Industrial environments demand stringent requirements for “space adaptability, environmental resilience, and functional scalability.” The QY-B5000 features targeted optimizations from hardware design to interface configuration, delivering five irreplaceable advantages:

1. Compact Size + Multiple Mounting Options

Industrial control cabinets, AGV chassis, and equipment mounting bays demand extremely compact devices. The QY-B5000 features a lightweight design, measuring just 1/8 the size of traditional industrial PCs. It easily fits into standard 30cm-deep control cabinets while supporting desktop / embedded / wall-mount/rail-mount configurations. For instance, in automotive welding workshops, it can be rail-mounted on production line pillars without occupying workbench space, resolving the core pain points of “equipment space constraints and installation limitations.”

2. Fanless + Fully Enclosed Aluminum Chassis

Dust, extreme temperatures, and vibration in industrial environments are primary causes of equipment failure. The QY-B5000 mitigates these risks through a dual-design approach of “passive cooling + material protection”:

Fanless thermal conduction: Replaces traditional fans (prone to dust accumulation) with a fully enclosed aluminum alloy chassis that directly conducts heat through the metal casing. This boosts cooling efficiency by 40% while preventing dust intrusion into internal components, making it suitable for high-dust environments like mines and building material plants.

Extreme Temperature & Interference Resistance: Supports continuous operation from -30°C to 60°C (far exceeding the industry average of -20°C to 50°C), ensuring stable performance in unheated northern workshops during winter and southern equipment rooms during summer. Passes EMC electromagnetic compatibility testing to withstand interference from inverters and motors, reducing failure rates by 80% in high-interference environments like substations and solar power plants.

Vibration-Resistant Design: Reinforced motherboard interfaces paired with SSD storage (no mechanical components) withstand 50-1000Hz vibrations. In high-vibration applications like logistics sorting lines and CNC machine tools, annual downtime is capped at 2 instances.

Industrial equipment requires 24/7 operation, where energy consumption and power supply compatibility directly impact costs. The QY-B5000 features 11th/12th/13th Gen Intel low-power Core processors (e.g., i5-1235U,i7-1355U), with full-load power consumption of just 35-45W. It also supports DC 9-36V wide-voltage input with overvoltage protection, eliminating the need for additional voltage regulators. This reduces deployment costs by 30% in non-standard power scenarios like outdoor solar power stations and mobile AGVs.

Industrial scenarios vary greatly in interface and functionality requirements. The QY-B5000 addresses customization needs with “full interfaces + multiple expansion slots”,

Interface Configuration: Features 2 x 2.5G Gigabit Ethernet ports (Intel 225V chip, 2.5x faster than standard Gigabit ports), 6 x COM ports (4 x RS-232 + 2 x RS-485/422/232 switchable),, 6 USB ports (4 USB 3.0 + 2 USB 2.0), 1 HDMI (4K resolution) + 1 VGA (1080P). Manufacturing can connect multiple PLCs and sensors via COM ports, while logistics can separate “data transmission + device control” through dual network ports to prevent network congestion;

Core requirements for industrial equipment maintenance are “minimal downtime and ease of operation.” The QY-B5000 supports Windows 10/11, Linux, and other mainstream industrial systems, ensuring seamless compatibility with MES manufacturing execution systems, PLC programming software, and configuration monitoring software (like Kingsoft). It can be deployed without secondary development.It also supports Intel AMT remote management technology, enabling engineers to remotely power on/off devices, deploy systems, and diagnose faults. Over 80% of software issues can be resolved remotely without on-site intervention, significantly reducing operational costs.

The advantages of industrial-grade mini PCs extend beyond theory, having been implemented across manufacturing, logistics, energy, and smart factories. They serve as “critical equipment” driving industrial intelligence:

1. Manufacturing: Production Line Data Acquisition and Real-Time Monitoring

In automotive, electronics, and machinery manufacturing, production lines require real-time collection of data from sensors (temperature, pressure, RPM), PLCs, and CNC machines. This data is transmitted to MES (Manufacturing Execution Systems) for analysis to optimize production processes.Traditional industrial control computers are bulky and difficult to install near production lines, causing data transmission delays (typically 1-3 seconds). Industrial-grade Mini PCs, however, can be mounted directly beside production lines. They collect data in real time via serial/network ports, keeping latency under 100ms.For example, an electronics contract manufacturer deployed 30 Mini PCs on its SMT placement line to collect real-time data on nozzle pressure and soldering temperature from placement machines. This system triggers immediate alerts upon detecting anomalies, reducing product defect rates from 2.5% to 0.8% and boosting production efficiency by 15%.

2. Logistics Industry: AGV Control and Warehouse Management

In smart warehouses, AGVs (Automated Guided Vehicles) require real-time dispatch system commands to transport goods. Simultaneously, equipment support is needed for barcode scanning on storage racks and inventory tracking.Industrial-grade Mini PCs, featuring low power consumption and vibration resistance, can be directly embedded into AGV chassis. They receive dispatch instructions via 4G/5G modules and utilize AI vision modules to identify cargo locations, enabling precise handling. At warehouse shelving ends, Mini PCs connect barcode scanners to cloud systems, updating inventory data within 1 second after scanning to eliminate manual counting errors.

Substations, PV power plants, and similar facilities are often located outdoors or in remote areas, facing extreme temperature fluctuations and strong electromagnetic interference. They require 24/7 monitoring of equipment operational status (e.g., voltage, current, PV panel power generation).Industrial-grade Mini PCs support wide-temperature operation and electromagnetic compatibility design, enabling stable performance within substation control cabinets. By connecting to power sensors via serial ports, they collect real-time data and transmit it to power monitoring platforms. Alerts are immediately pushed to maintenance personnel upon detecting voltage anomalies or equipment failures.After deploying 10 Mini PCs at a photovoltaic power station, equipment failure rates dropped from 8% to 2%, power generation data accuracy reached 99.9%, and maintenance response times decreased from 2 hours to 30 minutes.

Industry 4.0 emphasizes “edge computing + cloud collaboration,” where data undergoes preprocessing at the edge (near devices) to reduce redundant cloud uploads and accelerate response times.Industrial-grade Mini PCs, equipped with lightweight computing capabilities (supporting Intel Core i3/i5), serve as edge computing nodes. They filter and analyze production line data, uploading only critical information—such as fault alerts and output statistics—to the cloud.

No. Its fully enclosed aluminum alloy chassis serves not only as a casing but also as a “heat dissipation carrier.” It disperses heat into the air through metal conduction. Paired with a low-power processor (45W at full load), the chassis temperature remains only 48°C in a 60°C environment—well below the component tolerance limit (70°C). Overheating is not a concern.

Industrial-grade Mini PCs utilize industrial-grade components (e.g., wide-temperature capacitors, reinforced motherboards). Their design lifespan typically ranges from 5 to 8 years, meeting the “long-term stable operation” requirements of industrial equipment.

Yes, we are an industrial-grade consumer electronics factory with over 20+ years of experience. Our main products include industrial tablet PCs, industrial displays, fanless industrial computers, fully waterproof tablet PCs, car tablet PCs, explosion-proof displays, explosion-proof computers, industrial motherboards, KVM displays, and more.

We provide a 3-year warranty for all our products and offer lifetime maintenance.

Generally 1-3 Working Days After Payment For Samples. The Lead Time For Mass Production Depends On The Quantity.

Of Course , Including Software, Packaging, Product Logo, ETC, Consult Customer Service For More Details.

Typically wire transfer (T/T). For established partnerships, alternative payment terms may be considered.

Our products comply with ISO9001 quality system and CCC/CE/FCC/ROHS/CQC/EN50155/IEC EN 60945/EN 50121/EN 60601 standards.

For industrial enterprises, selecting a suitable industrial-grade Fanless Industrial Mini PC not only resolves current equipment operation and maintenance challenges but also reserves expansion space for future Industry 4.0 upgrades. If you are facing issues with bulky industrial equipment, high energy consumption, and difficult maintenance, learn more about IPCTECH industrial fanless mini PCs!

Core Advantages of the IPCTECH B5000 Industrial-Grade Mini PC

Industrial environments demand stringent requirements for “space adaptability, environmental resilience, and functional scalability.” The QY-B5000 features targeted optimizations from hardware design to interface configuration, delivering five irreplaceable advantages:

1. Compact Size + Multiple Mounting Options

Industrial control cabinets, AGV chassis, and equipment mounting bays demand extremely compact devices. The QY-B5000 features a lightweight design, measuring just 1/8 the size of traditional industrial PCs. It easily fits into standard 30cm-deep control cabinets while supporting desktop / embedded / wall-mount/rail-mount configurations. For instance, in automotive welding workshops, it can be rail-mounted on production line pillars without occupying workbench space, resolving the core pain points of “equipment space constraints and installation limitations.”

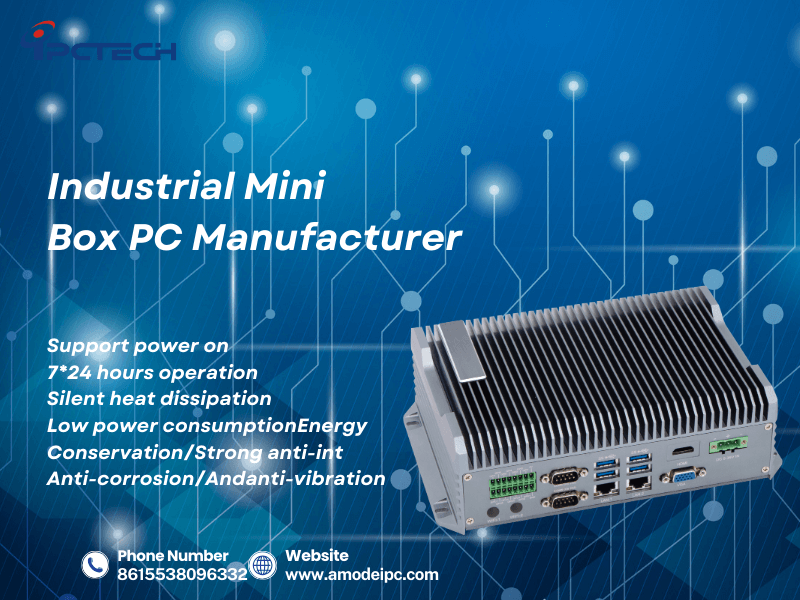

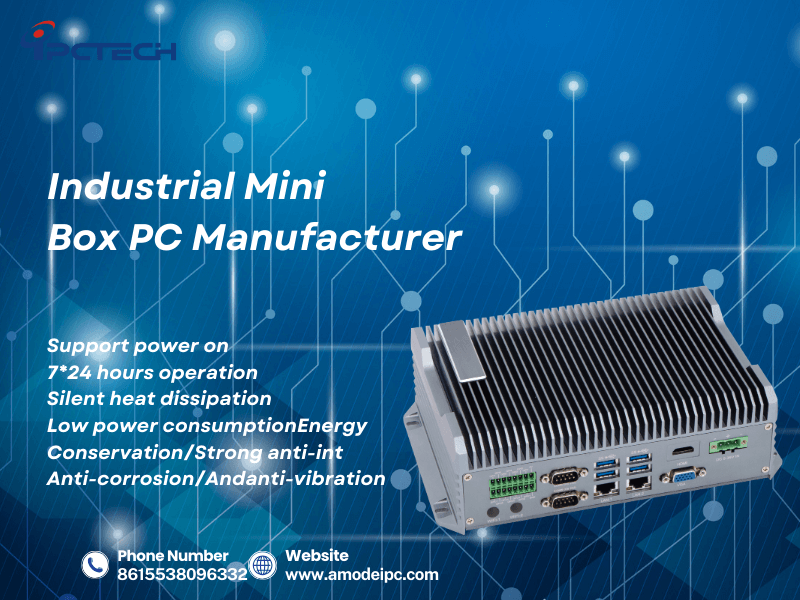

2. Fanless + Fully Enclosed Aluminum Chassis

Dust, extreme temperatures, and vibration in industrial environments are primary causes of equipment failure. The QY-B5000 mitigates these risks through a dual-design approach of “passive cooling + material protection”:

Fanless thermal conduction: Replaces traditional fans (prone to dust accumulation) with a fully enclosed aluminum alloy chassis that directly conducts heat through the metal casing. This boosts cooling efficiency by 40% while preventing dust intrusion into internal components, making it suitable for high-dust environments like mines and building material plants.

Extreme Temperature & Interference Resistance: Supports continuous operation from -30°C to 60°C (far exceeding the industry average of -20°C to 50°C), ensuring stable performance in unheated northern workshops during winter and southern equipment rooms during summer. Passes EMC electromagnetic compatibility testing to withstand interference from inverters and motors, reducing failure rates by 80% in high-interference environments like substations and solar power plants.

Vibration-Resistant Design: Reinforced motherboard interfaces paired with SSD storage (no mechanical components) withstand 50-1000Hz vibrations. In high-vibration applications like logistics sorting lines and CNC machine tools, annual downtime is capped at 2 instances.

3. Low Power Consumption + Wide Voltage Supply

Industrial equipment requires 24/7 operation, where energy consumption and power supply compatibility directly impact costs. The QY-B5000 features 11th/12th/13th Gen Intel low-power Core processors (e.g., i5-1235U,i7-1355U), with full-load power consumption of just 35-45W. It also supports DC 9-36V wide-voltage input with overvoltage protection, eliminating the need for additional voltage regulators. This reduces deployment costs by 30% in non-standard power scenarios like outdoor solar power stations and mobile AGVs.

4. Comprehensive Interfaces + Flexible Expansion

Industrial scenarios vary greatly in interface and functionality requirements. The QY-B5000 addresses customization needs with “full interfaces + multiple expansion slots”,

Interface Configuration: Features 2 x 2.5G Gigabit Ethernet ports (Intel 225V chip, 2.5x faster than standard Gigabit ports), 6 x COM ports (4 x RS-232 + 2 x RS-485/422/232 switchable),, 6 USB ports (4 USB 3.0 + 2 USB 2.0), 1 HDMI (4K resolution) + 1 VGA (1080P). Manufacturing can connect multiple PLCs and sensors via COM ports, while logistics can separate “data transmission + device control” through dual network ports to prevent network congestion;

5. High Compatibility + Remote Management

Core requirements for industrial equipment maintenance are “minimal downtime and ease of operation.” The QY-B5000 supports Windows 10/11, Linux, and other mainstream industrial systems, ensuring seamless compatibility with MES manufacturing execution systems, PLC programming software, and configuration monitoring software (like Kingsoft). It can be deployed without secondary development.It also supports Intel AMT remote management technology, enabling engineers to remotely power on/off devices, deploy systems, and diagnose faults. Over 80% of software issues can be resolved remotely without on-site intervention, significantly reducing operational costs.

Key Application Cases for Industrial-Grade Mini PCs

The advantages of industrial-grade mini PCs extend beyond theory, having been implemented across manufacturing, logistics, energy, and smart factories. They serve as “critical equipment” driving industrial intelligence:

1. Manufacturing: Production Line Data Acquisition and Real-Time Monitoring

In automotive, electronics, and machinery manufacturing, production lines require real-time collection of data from sensors (temperature, pressure, RPM), PLCs, and CNC machines. This data is transmitted to MES (Manufacturing Execution Systems) for analysis to optimize production processes.Traditional industrial control computers are bulky and difficult to install near production lines, causing data transmission delays (typically 1-3 seconds). Industrial-grade Mini PCs, however, can be mounted directly beside production lines. They collect data in real time via serial/network ports, keeping latency under 100ms.For example, an electronics contract manufacturer deployed 30 Mini PCs on its SMT placement line to collect real-time data on nozzle pressure and soldering temperature from placement machines. This system triggers immediate alerts upon detecting anomalies, reducing product defect rates from 2.5% to 0.8% and boosting production efficiency by 15%.

2. Logistics Industry: AGV Control and Warehouse Management

In smart warehouses, AGVs (Automated Guided Vehicles) require real-time dispatch system commands to transport goods. Simultaneously, equipment support is needed for barcode scanning on storage racks and inventory tracking.Industrial-grade Mini PCs, featuring low power consumption and vibration resistance, can be directly embedded into AGV chassis. They receive dispatch instructions via 4G/5G modules and utilize AI vision modules to identify cargo locations, enabling precise handling. At warehouse shelving ends, Mini PCs connect barcode scanners to cloud systems, updating inventory data within 1 second after scanning to eliminate manual counting errors.

3. Energy Sector: Substation / PV Power Plant Monitoring

Substations, PV power plants, and similar facilities are often located outdoors or in remote areas, facing extreme temperature fluctuations and strong electromagnetic interference. They require 24/7 monitoring of equipment operational status (e.g., voltage, current, PV panel power generation).Industrial-grade Mini PCs support wide-temperature operation and electromagnetic compatibility design, enabling stable performance within substation control cabinets. By connecting to power sensors via serial ports, they collect real-time data and transmit it to power monitoring platforms. Alerts are immediately pushed to maintenance personnel upon detecting voltage anomalies or equipment failures.After deploying 10 Mini PCs at a photovoltaic power station, equipment failure rates dropped from 8% to 2%, power generation data accuracy reached 99.9%, and maintenance response times decreased from 2 hours to 30 minutes.

4. Smart Factory: Edge Computing Nodes

Industry 4.0 emphasizes “edge computing + cloud collaboration,” where data undergoes preprocessing at the edge (near devices) to reduce redundant cloud uploads and accelerate response times.Industrial-grade Mini PCs, equipped with lightweight computing capabilities (supporting Intel Core i3/i5), serve as edge computing nodes. They filter and analyze production line data, uploading only critical information—such as fault alerts and output statistics—to the cloud.

FAQ of IPCTECH Industrial Mini PC

Will it overheat in high-temperature environments with its fanless design?

No. Its fully enclosed aluminum alloy chassis serves not only as a casing but also as a “heat dissipation carrier.” It disperses heat into the air through metal conduction. Paired with a low-power processor (45W at full load), the chassis temperature remains only 48°C in a 60°C environment—well below the component tolerance limit (70°C). Overheating is not a concern.

What is the lifespan of an industrial-grade Mini PC?

Industrial-grade Mini PCs utilize industrial-grade components (e.g., wide-temperature capacitors, reinforced motherboards). Their design lifespan typically ranges from 5 to 8 years, meeting the “long-term stable operation” requirements of industrial equipment.

Are You Manufacturer ?What Do You Mainly Supply With?

Yes, we are an industrial-grade consumer electronics factory with over 20+ years of experience. Our main products include industrial tablet PCs, industrial displays, fanless industrial computers, fully waterproof tablet PCs, car tablet PCs, explosion-proof displays, explosion-proof computers, industrial motherboards, KVM displays, and more.

How long is the warranty period for your products?

We provide a 3-year warranty for all our products and offer lifetime maintenance.

How Many Days Will Samples Be Finished? And How About The Mass Production?

Generally 1-3 Working Days After Payment For Samples. The Lead Time For Mass Production Depends On The Quantity.

Can You Provide OEM&ODM Special Customized Service?

Of Course , Including Software, Packaging, Product Logo, ETC, Consult Customer Service For More Details.

What Payment Methods Your Company Accept?

Typically wire transfer (T/T). For established partnerships, alternative payment terms may be considered.

How Do You Guarantee The Quality Of Your Products?

Our products comply with ISO9001 quality system and CCC/CE/FCC/ROHS/CQC/EN50155/IEC EN 60945/EN 50121/EN 60601 standards.

Conclusion

For industrial enterprises, selecting a suitable industrial-grade Fanless Industrial Mini PC not only resolves current equipment operation and maintenance challenges but also reserves expansion space for future Industry 4.0 upgrades. If you are facing issues with bulky industrial equipment, high energy consumption, and difficult maintenance, learn more about IPCTECH industrial fanless mini PCs!

Recommended