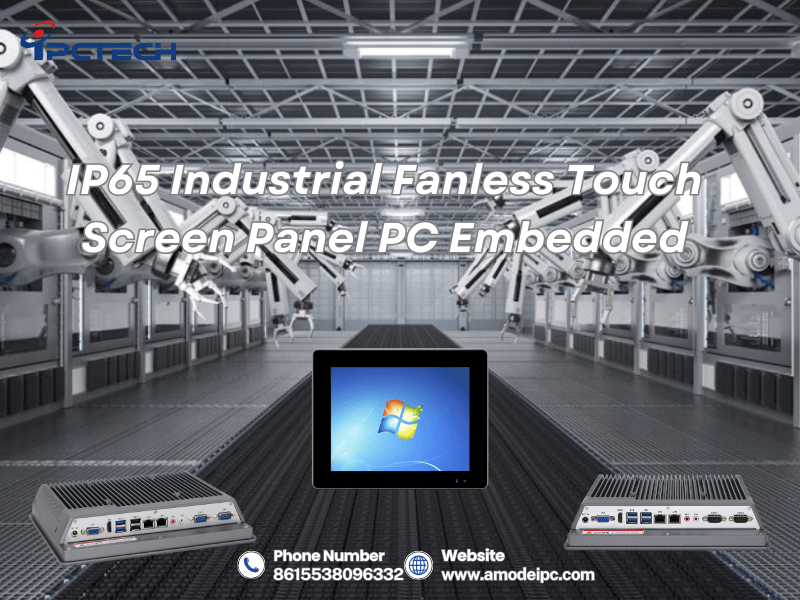

IPCTECH Fanless Industrial PC vs Fan Industrial PC

2025-08-31

In industrial automation, outdoor operations, and vehicle dispatch scenarios, industrial PCs serve as core terminals for data acquisition and equipment control. Their stability directly determines production efficiency and operational safety. While fan-equipped industrial PCs once held market share due to lower costs, fanless industrial PCs are increasingly becoming the mainstream choice across more industries. This shift is driven by the growing demand for enhanced environmental adaptability as industrial settings evolve toward high humidity, high vibration, and outdoor deployment.

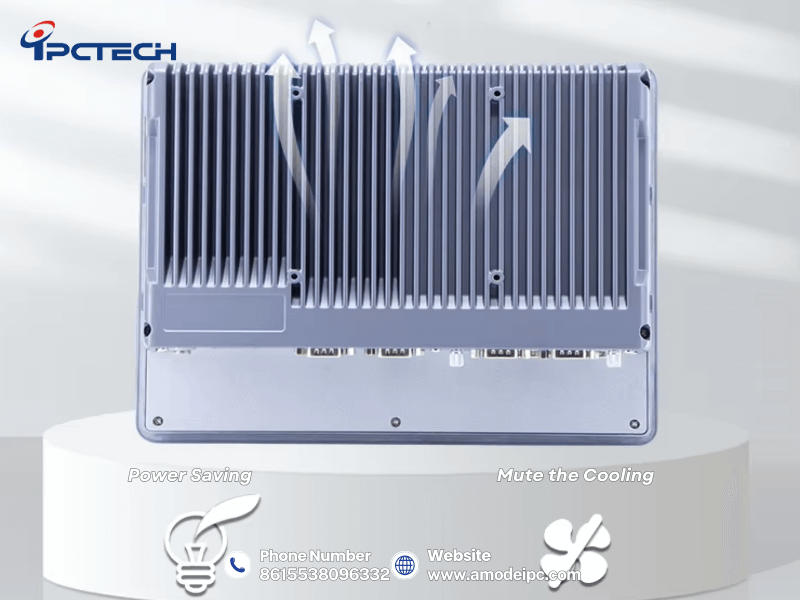

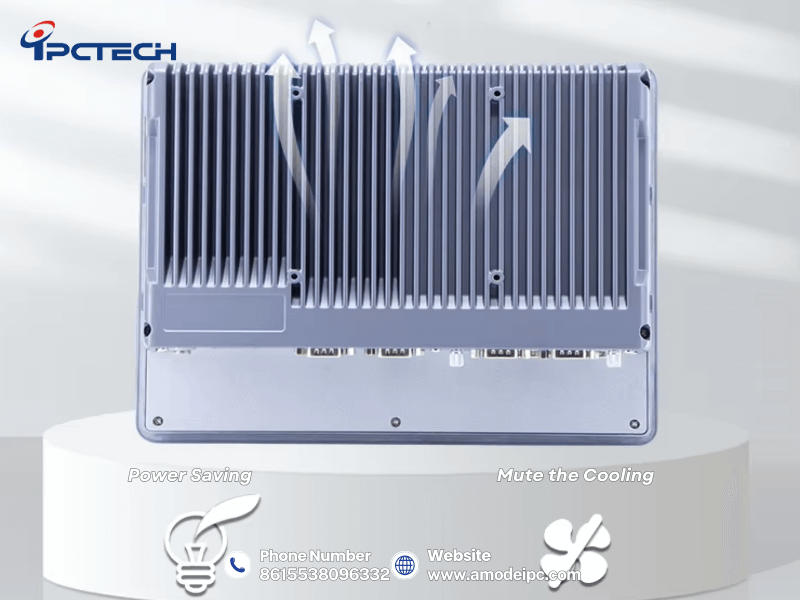

The design philosophy of fan-equipped industrial PCs centers on “active cooling + low cost,” using fans to forcibly expel heat. However, their mechanical structure and vented design expose significant weaknesses in harsh environments. Fanless industrial PCs, on the other hand, prioritize “passive cooling + fully sealed construction,” eliminating vulnerable components like fans to adapt to complex operating conditions.

Full-size coverage to meet diverse waterproofing requirements

The waterproof series includes 10.4-inch (compact size, ideal for handheld inspections), 12.1-inch (medium size, suitable for production line workstations), 13.3-inch / 15-inch (universal sizes, balancing display and operation), 15.6-inch / 17-inch (large sizes, perfect for workshop large-screen monitoring), 19-inch / 21.5-inch (extra-large, suitable for multi-person collaboration scenarios). This full size range meets installation and usage demands across diverse waterproof applications. For example: Outdoor solar inspections require portability—opt for the 10.4-inch handheld model; dairy filling lines need fixed monitoring—choose the 15.6-inch wall-mounted model.

Deep Customization to Address Unique Scenario Challenges

Unlike the “one-size-fits-all” design of fan-equipped PCs, we support on-demand customization to directly address personalized waterproofing needs:

Touch Customization: - Resistive touch for oil-prone environments (e.g., machining workshops) – operable with gloves, resistant to oil smudges; - Capacitive touch for clean environments (e.g., food packaging workshops) – multi-touch operation, easy to clean;

Interface Customization: For sensor/PLC connections, waterproof RS485 interfaces prevent liquid ingress; for outdoor power-free environments, POE interfaces enable power delivery via Ethernet cables (reducing wiring complexity).

Material Customization: For chemical workshops (corrosive liquids), upgrade to 316 stainless steel housing (acid/alkali resistant, 3x longer lifespan than standard aluminum alloy); for outdoor sun exposure, customize UV-resistant screens (prevents fading and touch failure from prolonged sunlight).

IP66 High Protection + Passive Cooling: Dual Assurance for Waterproof Stability

IPCTECH's waterproof tablet features a fully sealed enclosure with no ventilation holes. Combined with waterproof interface plugs (maintaining seal integrity after 1000 insertions/removals), it achieves IP66 waterproofing—far exceeding the IP54 rating of fan-equipped PCs.Simultaneously, the aluminum alloy casing serves dual functions as “structural support” and “passive heat dissipation,” evenly conducting CPU heat to the exterior for dispersion. Even under 35°C outdoor temperatures, the entire unit maintains temperatures below 55°C, preventing overheating shutdowns common in fan-equipped PCs when fans fail.

Suspension-mounted anti-vibration design for high-frequency vehicle jolts

In vehicle applications, truck travel vibrations (vibration acceleration ≤20m/s²) and excavator impact (vibration acceleration ≤30m/s²) can cause fan blade fractures and hard drive head damage in fan-equipped PCs. The fanless vehicle tablet employs a “suspended motherboard design”—— The motherboard is secured within the chassis by four elastic silicone pads (made of aging-resistant silicone material), reducing vibration transmission by over 90%. Additionally, the interface utilizes a vehicle-grade reinforced DB9 connector (with a plugging/unplugging lifespan exceeding 10,000 cycles, 5 times higher than standard interfaces), preventing data interruptions caused by connector loosening even on mountainous, bumpy roads.

12-36V wide voltage power supply adapts to all vehicle power requirements

Voltage requirements vary significantly across vehicle types: 12V for passenger cars, 24V for trucks, and 36V for construction machinery. Fan-equipped PCs typically require fixed 12V or 24V power, necessitating additional power converters. These converters are prone to damage from voltage spikes (e.g., truck startup surges to 40V), causing device crashes.Fanless vehicle-grade tablets integrate a wide-voltage power module supporting 12-36V adaptive input, enabling direct connection to vehicle power without additional accessories. They also feature overvoltage, overcurrent, and reverse-polarity protection, safeguarding devices even from wiring errors. This design accommodates all vehicle types, including logistics trucks, excavators, and ambulances.

Wide-Temperature Operation + Low Power Consumption for Sealed Vehicle Environments

Vehicle interiors experience extreme temperature fluctuations: summer sun exposure can push temperatures above 65°C (143°F), while winter outdoor conditions drop below -25°C (-49°F). Fan-equipped PCs (operating range: 0°C–40°C/32°F–104°F) cannot withstand these extremes, leading to screen freezes and CPU throttling. Fan noise (30–40dB) further disrupts medical procedures in ambulances or rest in RVs.Our fanless vehicle-grade tablet features an extended operating temperature range of -30°C to 70°C, ensuring stable performance under extreme conditions. Its zero-noise design meets silent operation requirements. With total power consumption ≤20W, it can run for 5 hours on the vehicle battery after the engine is turned off, meeting temporary dispatch needs and avoiding battery depletion caused by excessive power consumption of fan-based PCs.

Liquid-Exposed Environments: Food processing (rinse cycles), aquaculture (high humidity), outdoor operations in rainy conditions (rain exposure) require IP66/IP67 protection;

High-vibration environments: Logistics trucks, excavators, forklifts—requiring vibration resistance ≥20m/s²;

Outdoor or unattended operation: Solar power plants, mountainous base stations—requiring wide temperature (-20°C to 60°C) and low power consumption (supporting battery operation);

Noise-sensitive applications: Ambulances, precision electronics workshops—requiring zero-noise operation.

The fanless design eliminates vulnerable mechanical components like fans and heat sinks, preventing equipment failures caused by bearing aging or dust jamming. Mean Time Between Failures (MTBF) typically exceeds 50,000 hours—significantly higher than fan-equipped models—drastically reducing downtime risks in industrial settings.

To achieve fanless cooling, the chassis typically features an aluminum alloy monocoque construction with full sealing. Dust and water resistance ratings reach IP65/IP67/IP68, effectively blocking industrial contaminants like dust, oil, and liquid splashes (e.g., workshop washdowns, outdoor rain exposure). This prevents pollutants from infiltrating internal circuits and causing short circuits.

Leveraging passive cooling technology (heat dissipation through the chassis) and low-power hardware configurations, these systems operate reliably within a wide temperature range of -20°C to 60°C (some high-end models extend to -30°C to 70°C). They withstand summer outdoor exposure, workshop heat, winter cold, and cold chain environments without requiring additional temperature control equipment.

With no fan-driven mechanical components, the system operates at 0dB, making it ideal for noise-sensitive industrial settings like ambulance medical monitoring, precision electronics assembly, and laboratory data collection. Eliminates fan noise interference with operations or environmental comfort.

Equipped with low-power processors, total power consumption is typically controlled between 15-30W—only 1/2 to 2/3 that of fan-equipped models. This reduces long-term electricity expenses while enabling battery operation for outdoor handheld inspections, mobile tasks, and other scenarios without external power sources.

Eliminates the need for periodic fan disassembly to clear dust, replace aging fans or cooling components. Routine maintenance involves only surface cleaning, with annual maintenance costs averaging 1/5 to 1/3 of fan-equipped models. Particularly suitable for unmanned scenarios (e.g., solar power plants, mountainous base stations), reducing remote maintenance labor and time costs.

Eliminates CPU overheating, throttling, and system crashes caused by fan failure in ventilated models. Fanless passive cooling evenly dissipates heat, ensuring long-term stable operation of processors and storage modules. This minimizes risks of data loss or interruptions during industrial data acquisition and equipment control processes.

The fanless design eliminates the need for dedicated cooling channels, enabling thinner (typically ≤50mm) and smaller form factors. This adapts to confined industrial installation spaces—such as embedded cabinet mounting, vehicle dashboard integration, or wall-mounted setups—without occupying additional workspace.

The absence of fan-driven mechanical components minimizes vibration transmission points. Certain models further enhance vibration resistance through suspended motherboard designs and reinforced interfaces (e.g., DB9, USB Type-C industrial connectors), achieving vibration resistance ratings compliant with IEC 60068-2-6 standards (sine wave vibration 10-500Hz, acceleration ≥20m/s²).suitable for mobile industrial environments like logistics trucks, excavators, and forklifts.

Supports commonly used industrial hardware interfaces (e.g., RS485, CAN bus, POE power supply, HDMI) for flexible connection to peripherals like sensors, PLCs, cameras, and printers. Compatible with industrial operating systems including Windows 10 IoT and Linux. Select models support memory and storage expansion, enabling functional customization for diverse industrial requirements and multi-scenario applications.

As a specialized R&D manufacturer deeply rooted in the fanless industrial panel PC sector, we focus on meeting industrial users' equipment needs in complex environments. We have developed a comprehensive product portfolio spanning the full size range from 10.4 inches to 21.5 inches —— From IP66/IP67 waterproof series (suited for food processing, outdoor inspections, and other humid scenarios) to vehicle-mounted series compliant with IEC 60068-2-6 vibration standards (designed for logistics trucks, construction machinery, and other mobile applications),Every product undergoes rigorous environmental testing (extreme temperatures, waterproofing, vibration) and long-term stability validation to ensure “zero-failure” operation in industrial settings.

Beyond premium products, we are committed to providing full-process service assurance: During the pre-sales phase, our professional technical team thoroughly understands your operational pain points, offering complimentary equipment selection plans and installation recommendations. During the sales phase, we provide on-site installation guidance to ensure rapid deployment and commissioning. In the after-sales phase, we maintain a 24/7 response mechanism, delivering immediate technical support for malfunctions. For remote areas, we coordinate nearby service points for on-site repairs, minimizing your downtime losses.

Whether you're a food processing company upgrading production line monitoring equipment, a logistics firm planning to deploy intelligent vehicle dispatch systems, or a solar/engineering enterprise seeking stable outdoor inspection terminals, we can be your most trusted Industrial Panel PC distributor for industrial intelligence transformation. Our highly adaptable products, flexible customization solutions, and reliable services deliver the solutions you need.Reach out directly to our sales team to explore collaboration opportunities. Let our stable, high-performance fanless industrial panel PCs inject new momentum into your production efficiency and cost optimization.

Fanless Industrial PC vs Fan Industrial PC

The design philosophy of fan-equipped industrial PCs centers on “active cooling + low cost,” using fans to forcibly expel heat. However, their mechanical structure and vented design expose significant weaknesses in harsh environments. Fanless industrial PCs, on the other hand, prioritize “passive cooling + fully sealed construction,” eliminating vulnerable components like fans to adapt to complex operating conditions.

| Comparison Dimensions | Fan Industrial PC | Fanless Industrial PC |

| Structural and Protective Design | Reserve ventilation holes for fan cooling. Interfaces feature no sealing or only basic sealing, with protection ratings typically ranging from IP40 to IP54. | Fully sealed enclosure (integrated aluminum alloy casting), interfaces with waterproof rubber plugs, waterproof rating up to IP66/IP67 |

| Reliability (MTBF) | Fans are consumable components. Bearing aging and dust jamming can easily cause failures, with MTBF approximately 20,000–30,000 hours. | No mechanical moving parts, relies on passive heat dissipation via enclosure, MTBF ≥ 50,000 hours |

| Environmental Adaptability | Operating temperature range is typically 0°C-40°C, with low vibration resistance (≤10m/s²), unable to withstand extreme temperature and vibration conditions. | Wide temperature range (-20°C to 60°C; vehicle-mounted series: -30°C to 70°C), vibration resistance rating IEC 60068-2-6 (≤50 m/s²) |

| Power Consumption and Noise | Fans consume additional power (total system power consumption 30-60W) and generate operating noise of 30-40dB. | Low-power CPU, total system power consumption 15-30W, zero noise |

| Maintenance Costs | Requires dust cleaning and replacement of worn fans every 3-6 months, resulting in high maintenance costs. | Fanless, no consumables; requires only annual visual inspection, low average annual maintenance cost |

| Customization Capabilities | Primarily standardized models with inflexible interfaces and housing materials, making adaptation to specialized scenarios difficult. | Waterproof series supports full-size customization (10.4“ - 21.5”), touch methods (resistive/capacitive), interfaces (waterproof RS485/POE), and enclosures (aluminum alloy) |

Why choose IPCTECH Industrial Panel PC Computer?

Fanless Industrial PC Waterproof Solution Manufacturer

Full-size coverage to meet diverse waterproofing requirements

The waterproof series includes 10.4-inch (compact size, ideal for handheld inspections), 12.1-inch (medium size, suitable for production line workstations), 13.3-inch / 15-inch (universal sizes, balancing display and operation), 15.6-inch / 17-inch (large sizes, perfect for workshop large-screen monitoring), 19-inch / 21.5-inch (extra-large, suitable for multi-person collaboration scenarios). This full size range meets installation and usage demands across diverse waterproof applications. For example: Outdoor solar inspections require portability—opt for the 10.4-inch handheld model; dairy filling lines need fixed monitoring—choose the 15.6-inch wall-mounted model.

Deep Customization to Address Unique Scenario Challenges

Unlike the “one-size-fits-all” design of fan-equipped PCs, we support on-demand customization to directly address personalized waterproofing needs:

Touch Customization: - Resistive touch for oil-prone environments (e.g., machining workshops) – operable with gloves, resistant to oil smudges; - Capacitive touch for clean environments (e.g., food packaging workshops) – multi-touch operation, easy to clean;

Interface Customization: For sensor/PLC connections, waterproof RS485 interfaces prevent liquid ingress; for outdoor power-free environments, POE interfaces enable power delivery via Ethernet cables (reducing wiring complexity).

Material Customization: For chemical workshops (corrosive liquids), upgrade to 316 stainless steel housing (acid/alkali resistant, 3x longer lifespan than standard aluminum alloy); for outdoor sun exposure, customize UV-resistant screens (prevents fading and touch failure from prolonged sunlight).

IP66 High Protection + Passive Cooling: Dual Assurance for Waterproof Stability

IPCTECH's waterproof tablet features a fully sealed enclosure with no ventilation holes. Combined with waterproof interface plugs (maintaining seal integrity after 1000 insertions/removals), it achieves IP66 waterproofing—far exceeding the IP54 rating of fan-equipped PCs.Simultaneously, the aluminum alloy casing serves dual functions as “structural support” and “passive heat dissipation,” evenly conducting CPU heat to the exterior for dispersion. Even under 35°C outdoor temperatures, the entire unit maintains temperatures below 55°C, preventing overheating shutdowns common in fan-equipped PCs when fans fail.

Fanless Industrial PC Vehicle Series Solution Factory

Suspension-mounted anti-vibration design for high-frequency vehicle jolts

In vehicle applications, truck travel vibrations (vibration acceleration ≤20m/s²) and excavator impact (vibration acceleration ≤30m/s²) can cause fan blade fractures and hard drive head damage in fan-equipped PCs. The fanless vehicle tablet employs a “suspended motherboard design”—— The motherboard is secured within the chassis by four elastic silicone pads (made of aging-resistant silicone material), reducing vibration transmission by over 90%. Additionally, the interface utilizes a vehicle-grade reinforced DB9 connector (with a plugging/unplugging lifespan exceeding 10,000 cycles, 5 times higher than standard interfaces), preventing data interruptions caused by connector loosening even on mountainous, bumpy roads.

12-36V wide voltage power supply adapts to all vehicle power requirements

Voltage requirements vary significantly across vehicle types: 12V for passenger cars, 24V for trucks, and 36V for construction machinery. Fan-equipped PCs typically require fixed 12V or 24V power, necessitating additional power converters. These converters are prone to damage from voltage spikes (e.g., truck startup surges to 40V), causing device crashes.Fanless vehicle-grade tablets integrate a wide-voltage power module supporting 12-36V adaptive input, enabling direct connection to vehicle power without additional accessories. They also feature overvoltage, overcurrent, and reverse-polarity protection, safeguarding devices even from wiring errors. This design accommodates all vehicle types, including logistics trucks, excavators, and ambulances.

Wide-Temperature Operation + Low Power Consumption for Sealed Vehicle Environments

Vehicle interiors experience extreme temperature fluctuations: summer sun exposure can push temperatures above 65°C (143°F), while winter outdoor conditions drop below -25°C (-49°F). Fan-equipped PCs (operating range: 0°C–40°C/32°F–104°F) cannot withstand these extremes, leading to screen freezes and CPU throttling. Fan noise (30–40dB) further disrupts medical procedures in ambulances or rest in RVs.Our fanless vehicle-grade tablet features an extended operating temperature range of -30°C to 70°C, ensuring stable performance under extreme conditions. Its zero-noise design meets silent operation requirements. With total power consumption ≤20W, it can run for 5 hours on the vehicle battery after the engine is turned off, meeting temporary dispatch needs and avoiding battery depletion caused by excessive power consumption of fan-based PCs.

IPCTECH Fanless Industrial Panel PCs Application

Scenarios Requiring Fanless Industrial PCs

Liquid-Exposed Environments: Food processing (rinse cycles), aquaculture (high humidity), outdoor operations in rainy conditions (rain exposure) require IP66/IP67 protection;

High-vibration environments: Logistics trucks, excavators, forklifts—requiring vibration resistance ≥20m/s²;

Outdoor or unattended operation: Solar power plants, mountainous base stations—requiring wide temperature (-20°C to 60°C) and low power consumption (supporting battery operation);

Noise-sensitive applications: Ambulances, precision electronics workshops—requiring zero-noise operation.

Benefits of Fanless Industrial Panel PC

High Durability, Lower Failure Rate

The fanless design eliminates vulnerable mechanical components like fans and heat sinks, preventing equipment failures caused by bearing aging or dust jamming. Mean Time Between Failures (MTBF) typically exceeds 50,000 hours—significantly higher than fan-equipped models—drastically reducing downtime risks in industrial settings.

Fully Sealed Protection for Harsh Environments

To achieve fanless cooling, the chassis typically features an aluminum alloy monocoque construction with full sealing. Dust and water resistance ratings reach IP65/IP67/IP68, effectively blocking industrial contaminants like dust, oil, and liquid splashes (e.g., workshop washdowns, outdoor rain exposure). This prevents pollutants from infiltrating internal circuits and causing short circuits.

Wide Temperature Operation, Unfazed by Extreme Conditions

Leveraging passive cooling technology (heat dissipation through the chassis) and low-power hardware configurations, these systems operate reliably within a wide temperature range of -20°C to 60°C (some high-end models extend to -30°C to 70°C). They withstand summer outdoor exposure, workshop heat, winter cold, and cold chain environments without requiring additional temperature control equipment.

Zero-noise operation for quiet environments

With no fan-driven mechanical components, the system operates at 0dB, making it ideal for noise-sensitive industrial settings like ambulance medical monitoring, precision electronics assembly, and laboratory data collection. Eliminates fan noise interference with operations or environmental comfort.

Low power consumption for cost savings

Equipped with low-power processors, total power consumption is typically controlled between 15-30W—only 1/2 to 2/3 that of fan-equipped models. This reduces long-term electricity expenses while enabling battery operation for outdoor handheld inspections, mobile tasks, and other scenarios without external power sources.

Low maintenance costs, reduced labor investment

Eliminates the need for periodic fan disassembly to clear dust, replace aging fans or cooling components. Routine maintenance involves only surface cleaning, with annual maintenance costs averaging 1/5 to 1/3 of fan-equipped models. Particularly suitable for unmanned scenarios (e.g., solar power plants, mountainous base stations), reducing remote maintenance labor and time costs.

High operational stability with zero data loss

Eliminates CPU overheating, throttling, and system crashes caused by fan failure in ventilated models. Fanless passive cooling evenly dissipates heat, ensuring long-term stable operation of processors and storage modules. This minimizes risks of data loss or interruptions during industrial data acquisition and equipment control processes.

Compact structure for flexible installation

The fanless design eliminates the need for dedicated cooling channels, enabling thinner (typically ≤50mm) and smaller form factors. This adapts to confined industrial installation spaces—such as embedded cabinet mounting, vehicle dashboard integration, or wall-mounted setups—without occupying additional workspace.

Robust vibration resistance for mobile applications

The absence of fan-driven mechanical components minimizes vibration transmission points. Certain models further enhance vibration resistance through suspended motherboard designs and reinforced interfaces (e.g., DB9, USB Type-C industrial connectors), achieving vibration resistance ratings compliant with IEC 60068-2-6 standards (sine wave vibration 10-500Hz, acceleration ≥20m/s²).suitable for mobile industrial environments like logistics trucks, excavators, and forklifts.

High Compatibility and Expandability

Supports commonly used industrial hardware interfaces (e.g., RS485, CAN bus, POE power supply, HDMI) for flexible connection to peripherals like sensors, PLCs, cameras, and printers. Compatible with industrial operating systems including Windows 10 IoT and Linux. Select models support memory and storage expansion, enabling functional customization for diverse industrial requirements and multi-scenario applications.

Fanless Industrial Panel PCs Solution-IPCTECH

As a specialized R&D manufacturer deeply rooted in the fanless industrial panel PC sector, we focus on meeting industrial users' equipment needs in complex environments. We have developed a comprehensive product portfolio spanning the full size range from 10.4 inches to 21.5 inches —— From IP66/IP67 waterproof series (suited for food processing, outdoor inspections, and other humid scenarios) to vehicle-mounted series compliant with IEC 60068-2-6 vibration standards (designed for logistics trucks, construction machinery, and other mobile applications),Every product undergoes rigorous environmental testing (extreme temperatures, waterproofing, vibration) and long-term stability validation to ensure “zero-failure” operation in industrial settings.

Beyond premium products, we are committed to providing full-process service assurance: During the pre-sales phase, our professional technical team thoroughly understands your operational pain points, offering complimentary equipment selection plans and installation recommendations. During the sales phase, we provide on-site installation guidance to ensure rapid deployment and commissioning. In the after-sales phase, we maintain a 24/7 response mechanism, delivering immediate technical support for malfunctions. For remote areas, we coordinate nearby service points for on-site repairs, minimizing your downtime losses.

Whether you're a food processing company upgrading production line monitoring equipment, a logistics firm planning to deploy intelligent vehicle dispatch systems, or a solar/engineering enterprise seeking stable outdoor inspection terminals, we can be your most trusted Industrial Panel PC distributor for industrial intelligence transformation. Our highly adaptable products, flexible customization solutions, and reliable services deliver the solutions you need.Reach out directly to our sales team to explore collaboration opportunities. Let our stable, high-performance fanless industrial panel PCs inject new momentum into your production efficiency and cost optimization.

Recommended