How Does Fanless Design Enhance Mini PC Reliability and Stability

2025-09-08

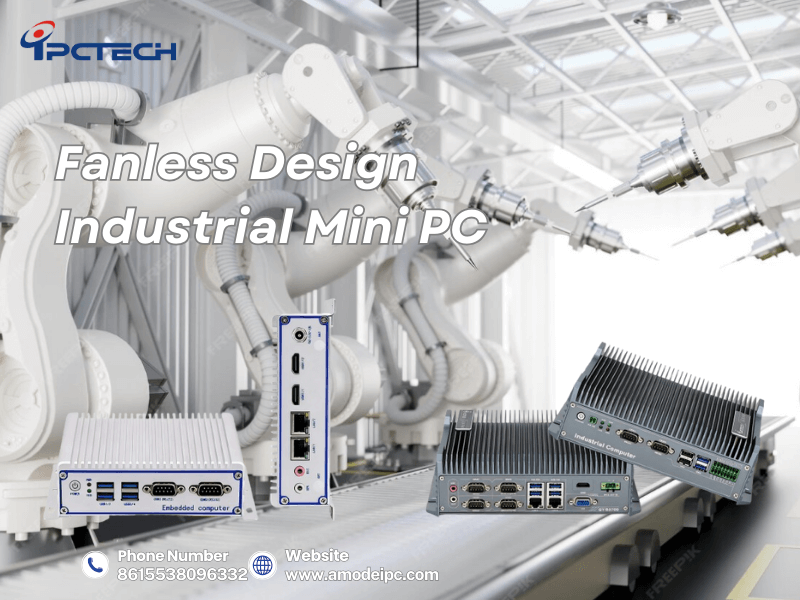

Today, demand for mini PCs is surging across both professional fields (such as industrial automation and digital signage) and consumer sectors (like home entertainment and home offices). However, traditional fan-equipped mini PCs face numerous reliability and stability challenges, with issues like dust accumulation and mechanical failures frequently occurring. Fanless design fundamentally resolves these pain points by eliminating moving parts, directly enhancing the long-term reliability, operational stability, and user experience of mini PCs.

Fan-equipped mini PCs suffer from a critical flaw—the fan itself is a single point of failure. Issues like motor wear, bearing degradation, and wiring deterioration are commonplace. Data reveals that in typical mini PC environments, standard fans average only 3,000–5,000 hours of operation, whereas fanless components can last over 10,000 hours. In practical applications, fan failures can trigger cascading issues. In critical scenarios like retail POS systems or industrial control panels, fan damage leads to device overheating, sudden shutdowns, and even data loss. Conversely, fanless designs eliminate mechanical failure risks entirely by removing moving parts, significantly extending the mini PC's Mean Time Between Failures (MTBF).

During operation, fans accelerate the ingress of contaminants. The airflow they generate sucks dust, lint, and debris into the mini PC chassis, where these impurities accumulate on printed circuit boards (PCBs), central processing units (CPUs), and capacitors. Dust buildup has severe consequences: it reduces thermal conductivity efficiency, causing device overheating, and may also trigger short circuits or corrode sensitive components. Fanless designs effectively counter these issues. Most commercially available fanless mini PCs utilize sealed or semi-sealed enclosures that block external contaminants from reaching internal hardware. Case studies demonstrate that in dusty industrial warehouse environments, fanless mini PCs require 80% less maintenance than fan-equipped models, clearly highlighting their dust-proof advantages.

Many mistakenly believe fanless designs compromise thermal performance. In reality, they rely on passive cooling solutions—such as heat sinks, thermal pads, and aluminum chassis—which evenly distribute heat through high-thermal-conductivity materials and dissipate it into the surrounding environment without forced airflow. From a stability perspective, fan-equipped mini PCs experience fluctuating fan speeds during load changes, whereas fanless designs maintain consistent CPU and GPU temperatures, effectively preventing thermal throttling. Take fanless mini PCs equipped with Intel Celeron N5105 or AMD Ryzen 5 7535U processors as an example. During 24-hour continuous operation, they exhibit no sudden temperature spikes and consistently deliver stable performance.

Fan operation generates vibrations. Even with minimal amplitude, these vibrations accumulate over time and transmit to internal components like hard disk drives (HDDs), solid-state drives (SSDs), and memory modules (RAM). The risks posed by vibration are significant: it can damage HDD platters, leading to data corruption; cause RAM connections to loosen, triggering blue screen failures; and shorten SSD lifespan. Fanless designs achieve vibration-free operation, which is critical for mini PCs used in data-sensitive scenarios like home servers and surveillance DVRs. Industry test data indicates that in mini PCs equipped with HDDs, fanless models experience 30% fewer data read/write errors than models with fans.

Fan failures trigger chain reactions: when a fan malfunctions, components like the CPU and power supply must work overtime, shortening their lifespan. Fanless designs provide superior operating conditions—lower temperatures, cleaner environments, and vibration-free operation—effectively protecting critical parts like capacitors and voltage regulators from premature aging. From a total cost of ownership perspective, fanless mini PCs incur lower maintenance costs without frequent fan replacements. Their replacement cycles are extended, typically lasting 5-7 years, compared to 3-4 years for fan-equipped models. In digital signage network applications, for instance, fanless mini PCs reduce annual maintenance expenses by 40% compared to their fan-equipped counterparts, significantly lowering operational costs for businesses.

Fan noise is a major limitation of traditional mini PCs, typically operating between 30-50 decibels, making them unsuitable for noise-sensitive environments like libraries, bedrooms, or recording studios. Fanless mini PCs, however, produce extremely low operational noise—often below 20 decibels—achieving near-silent operation. This enables their use in demanding scenarios such as home theater PCs and office workstations where minimal noise is critical. From a user experience perspective, the silent fanless design minimizes distractions, enhancing productivity and comfort during extended usage. According to 2024 consumer survey data, 65% of mini PC buyers prioritize "silent operation," with fanless models dominating this segment.

To fully leverage the advantages of fanless design and ensure optimal reliability and stability in mini PCs, several key considerations exist during design and operation. First is component selection: prioritize low-power CPUs (Thermal Design Power TDP < 15W) and high-efficiency SSDs to minimize heat generation. Second is chassis material—opt for aluminum or magnesium alloy chassis, which offer excellent passive heat dissipation properties. Additionally, environmental factors must be considered. Fanless mini PCs perform best within a 0-40°C (32-104°F) operating range and should be avoided in extreme temperature conditions. Finally, installation best practices include placing the unit on a flat, well-ventilated surface and avoiding enclosed cabinets to maximize heat dissipation.

IPCTECH has been deeply engaged in the industrial computer field for years. With profound insights into industrial application needs and robust R&D capabilities, we consistently lead the industry in designing, manufacturing, and innovating fanless mini PC products. The company remains committed to its core objective of "providing users with highly reliable, stable industrial-grade computing solutions." Strict quality control is maintained throughout every stage—from component selection to manufacturing—ensuring products withstand complex and harsh industrial environments. Our fanless mini PC series not only holds multiple authoritative industry certifications but also offers customized solutions tailored to diverse industry-specific needs. Widely deployed across smart manufacturing, intelligent healthcare, smart transportation, and smart security sectors, our products have earned high recognition from both the market and users, establishing us as a trusted partner for enterprises upgrading their industrial automation systems.

In summary, fanless design delivers several critical advantages for mini PCs, including eliminating mechanical failure risks, providing dust resistance, ensuring stable thermal management, reducing vibration, extending component lifespan, and enabling silent operation. In the future, fanless designs will see increasingly widespread adoption across industrial, commercial, and consumer mini PC markets. For users prioritizing 24/7 uninterrupted reliability, low maintenance requirements, and stable performance, fanless mini PCs are undoubtedly the optimal choice. Finally, when selecting a fanless mini PC, it is recommended to focus on its thermal design, component quality, and the warranty services provided by the manufacturer to ensure purchasing a high-quality product that meets your specific needs.

1. Q: How should I choose between the QY-B5300 and QY-B5700 fanless mini PCs based on usage scenarios?

A: If your application has limited space (e.g., small industrial control cabinets, compact device integration), requires an operating temperature range of -20°C to 60°C, and needs flexible processor options (from entry-level J1900 to high-performance 13th Gen Core i7), prioritize the QY-B5300. If your application involves extreme temperatures (e.g., high-heat workshops, outdoor frigid environments, operating range -30°C to 70°C), requires additional storage interfaces (2 SATA SSDs + 1 mSATA SSD) for data reliability, and needs overvoltage/overcurrent protection for enhanced device safety, the QY-B5700 is the more suitable choice.

2. Q: Both fanless mini PCs feature fully enclosed chassis. Is internal dust cleaning required after long-term use?

A: No internal dust cleaning is required. The fully enclosed aluminum alloy chassis design of both the QY-B5300 and QY-B5700 effectively blocks external dust and debris from entering the device, preventing dust accumulation at the source. Compared to traditional fan-based devices, this significantly reduces maintenance frequency, making them particularly suitable for dusty industrial workshops, outdoor data stations, and similar environments.

3. Q: Does the fanless design of the QY-B5300, which supports 13th Gen Intel Core processors, adequately handle thermal demands under high load?

A: Absolutely. Both models utilize an aluminum alloy chassis as the core passive cooling medium. Through an optimized internal thermal conduction structure (combined with thermal pads and heat sinks), heat generated by the processor is rapidly transferred to the chassis exterior for dissipation. Even when the QY-B5300 runs a 13th Gen Core i7 processor under heavy workloads (e.g., industrial data processing, multi-task control), it maintains stable temperatures. This prevents performance throttling due to overheating, ensuring 24/7 continuous operation.

4. Q: Can special interfaces (e.g., RS485, HDMI 2.1) be customized for the QY-B5300 or QY-B5700?

A: Customization is supported. AMODE IPC offers interface customization services for both fanless mini PCs based on industry-specific requirements (e.g., multiple RS485 ports for industrial automation device coordination, HDMI 2.1 support for 4K high-refresh-rate displays in digital signage). Customized devices retain the reliability and sealing integrity of the original fanless design.

5. Q: What is the warranty period for both products? What is the after-sales process if a fault occurs?

A: Both QY-B5300 and QY-B5700 come with a 2-year full-unit warranty (extendable to 3 years for industrial-grade components). For device malfunctions, submit a request via the "After-Sales Support" section on our official website (https://www.amodeipc.com/) or contact customer service directly. Our support team will respond within 24 hours to provide remote troubleshooting guidance. For on-site repairs, we will coordinate the nearest service point based on your location to minimize equipment downtime in industrial settings.

6. Q: What specific power anomalies does the QY-B5700's overvoltage and overcurrent protection function address?

A: This feature addresses common industrial power fluctuations (e.g., transient voltage spikes or dips) and current overloads (e.g., sudden surges caused by external device short circuits). Upon detecting anomalies, the device automatically triggers protective mechanisms to cut off abnormal current/voltage inputs, preventing damage to core components (CPU, storage, power modules). It is particularly suitable for outdoor environments or industrial production lines with unstable power supplies.

Why choose a fanless mini PC?

Eliminating Mechanical Failure Points: The Cornerstone of Fanless Reliability

Fan-equipped mini PCs suffer from a critical flaw—the fan itself is a single point of failure. Issues like motor wear, bearing degradation, and wiring deterioration are commonplace. Data reveals that in typical mini PC environments, standard fans average only 3,000–5,000 hours of operation, whereas fanless components can last over 10,000 hours. In practical applications, fan failures can trigger cascading issues. In critical scenarios like retail POS systems or industrial control panels, fan damage leads to device overheating, sudden shutdowns, and even data loss. Conversely, fanless designs eliminate mechanical failure risks entirely by removing moving parts, significantly extending the mini PC's Mean Time Between Failures (MTBF).

Dust and Debris Protection: Safeguarding Internal Components

During operation, fans accelerate the ingress of contaminants. The airflow they generate sucks dust, lint, and debris into the mini PC chassis, where these impurities accumulate on printed circuit boards (PCBs), central processing units (CPUs), and capacitors. Dust buildup has severe consequences: it reduces thermal conductivity efficiency, causing device overheating, and may also trigger short circuits or corrode sensitive components. Fanless designs effectively counter these issues. Most commercially available fanless mini PCs utilize sealed or semi-sealed enclosures that block external contaminants from reaching internal hardware. Case studies demonstrate that in dusty industrial warehouse environments, fanless mini PCs require 80% less maintenance than fan-equipped models, clearly highlighting their dust-proof advantages.

Stable Thermal Management: Preventing Stability Issues Caused by Overheating

Many mistakenly believe fanless designs compromise thermal performance. In reality, they rely on passive cooling solutions—such as heat sinks, thermal pads, and aluminum chassis—which evenly distribute heat through high-thermal-conductivity materials and dissipate it into the surrounding environment without forced airflow. From a stability perspective, fan-equipped mini PCs experience fluctuating fan speeds during load changes, whereas fanless designs maintain consistent CPU and GPU temperatures, effectively preventing thermal throttling. Take fanless mini PCs equipped with Intel Celeron N5105 or AMD Ryzen 5 7535U processors as an example. During 24-hour continuous operation, they exhibit no sudden temperature spikes and consistently deliver stable performance.

Reduced Vibration: Protecting Sensitive Hardware and Data

Fan operation generates vibrations. Even with minimal amplitude, these vibrations accumulate over time and transmit to internal components like hard disk drives (HDDs), solid-state drives (SSDs), and memory modules (RAM). The risks posed by vibration are significant: it can damage HDD platters, leading to data corruption; cause RAM connections to loosen, triggering blue screen failures; and shorten SSD lifespan. Fanless designs achieve vibration-free operation, which is critical for mini PCs used in data-sensitive scenarios like home servers and surveillance DVRs. Industry test data indicates that in mini PCs equipped with HDDs, fanless models experience 30% fewer data read/write errors than models with fans.

Extending Internal Component Lifespan: Reducing Total Cost of Ownership

Fan failures trigger chain reactions: when a fan malfunctions, components like the CPU and power supply must work overtime, shortening their lifespan. Fanless designs provide superior operating conditions—lower temperatures, cleaner environments, and vibration-free operation—effectively protecting critical parts like capacitors and voltage regulators from premature aging. From a total cost of ownership perspective, fanless mini PCs incur lower maintenance costs without frequent fan replacements. Their replacement cycles are extended, typically lasting 5-7 years, compared to 3-4 years for fan-equipped models. In digital signage network applications, for instance, fanless mini PCs reduce annual maintenance expenses by 40% compared to their fan-equipped counterparts, significantly lowering operational costs for businesses.

Silent Operation: Expanding Mini PC Applications in Noise-Sensitive Environments

Fan noise is a major limitation of traditional mini PCs, typically operating between 30-50 decibels, making them unsuitable for noise-sensitive environments like libraries, bedrooms, or recording studios. Fanless mini PCs, however, produce extremely low operational noise—often below 20 decibels—achieving near-silent operation. This enables their use in demanding scenarios such as home theater PCs and office workstations where minimal noise is critical. From a user experience perspective, the silent fanless design minimizes distractions, enhancing productivity and comfort during extended usage. According to 2024 consumer survey data, 65% of mini PC buyers prioritize "silent operation," with fanless models dominating this segment.

Considerations for Fanless Design: Ensuring Optimal Reliability and Stability

To fully leverage the advantages of fanless design and ensure optimal reliability and stability in mini PCs, several key considerations exist during design and operation. First is component selection: prioritize low-power CPUs (Thermal Design Power TDP < 15W) and high-efficiency SSDs to minimize heat generation. Second is chassis material—opt for aluminum or magnesium alloy chassis, which offer excellent passive heat dissipation properties. Additionally, environmental factors must be considered. Fanless mini PCs perform best within a 0-40°C (32-104°F) operating range and should be avoided in extreme temperature conditions. Finally, installation best practices include placing the unit on a flat, well-ventilated surface and avoiding enclosed cabinets to maximize heat dissipation.

Industrial Mini PC Computer for Sale - IPCTECH

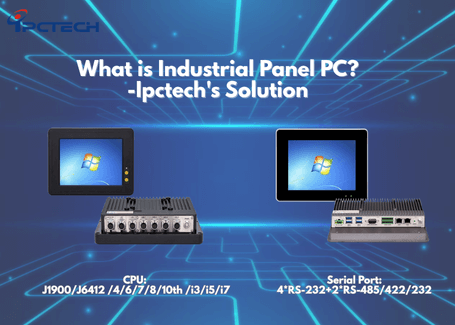

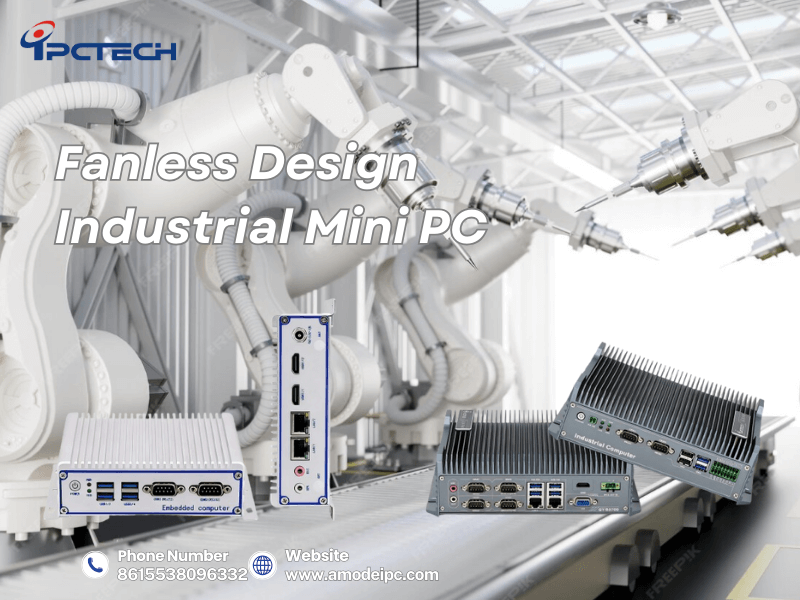

| TYPE | B-5300 | B-5700 |

| CPU: | N100, N2840, 4/5th-i3,i5,i7 J1900、6/7/8/10/12/13th-i3,i5,i7(optional) | i3-6157U,i3-7100U,i3-8130U,i3-10110U i5-7200U,i5-7260U,i5-8250U,i5-8260U,i5-10210U i7-7500U,i7-8550U,i7-10610U,i7-10710U |

| RAM: | 1*DDR 3 RAM slot up to 8GB | 1*DDR 4 RAM slot, up to 32GB |

| Storage: | 1*MSATA SSD, 1*SATA | 2*SATA SSD slot, 1*mSATA SSD slot |

| Interfaces: | 2*LAN, 6*USB,2*COM,1*HDMI,1*VGA | 2*LAN, 8*USB, 6*COM,1*HDMI, 1*VGA |

IPCTECH has been deeply engaged in the industrial computer field for years. With profound insights into industrial application needs and robust R&D capabilities, we consistently lead the industry in designing, manufacturing, and innovating fanless mini PC products. The company remains committed to its core objective of "providing users with highly reliable, stable industrial-grade computing solutions." Strict quality control is maintained throughout every stage—from component selection to manufacturing—ensuring products withstand complex and harsh industrial environments. Our fanless mini PC series not only holds multiple authoritative industry certifications but also offers customized solutions tailored to diverse industry-specific needs. Widely deployed across smart manufacturing, intelligent healthcare, smart transportation, and smart security sectors, our products have earned high recognition from both the market and users, establishing us as a trusted partner for enterprises upgrading their industrial automation systems.

Conclusion: Why Fanless Design is the Gold Standard for High-Reliability Mini PCs

In summary, fanless design delivers several critical advantages for mini PCs, including eliminating mechanical failure risks, providing dust resistance, ensuring stable thermal management, reducing vibration, extending component lifespan, and enabling silent operation. In the future, fanless designs will see increasingly widespread adoption across industrial, commercial, and consumer mini PC markets. For users prioritizing 24/7 uninterrupted reliability, low maintenance requirements, and stable performance, fanless mini PCs are undoubtedly the optimal choice. Finally, when selecting a fanless mini PC, it is recommended to focus on its thermal design, component quality, and the warranty services provided by the manufacturer to ensure purchasing a high-quality product that meets your specific needs.

FAQ for IPCTECH Industrial Mini PCs:

1. Q: How should I choose between the QY-B5300 and QY-B5700 fanless mini PCs based on usage scenarios?

A: If your application has limited space (e.g., small industrial control cabinets, compact device integration), requires an operating temperature range of -20°C to 60°C, and needs flexible processor options (from entry-level J1900 to high-performance 13th Gen Core i7), prioritize the QY-B5300. If your application involves extreme temperatures (e.g., high-heat workshops, outdoor frigid environments, operating range -30°C to 70°C), requires additional storage interfaces (2 SATA SSDs + 1 mSATA SSD) for data reliability, and needs overvoltage/overcurrent protection for enhanced device safety, the QY-B5700 is the more suitable choice.

2. Q: Both fanless mini PCs feature fully enclosed chassis. Is internal dust cleaning required after long-term use?

A: No internal dust cleaning is required. The fully enclosed aluminum alloy chassis design of both the QY-B5300 and QY-B5700 effectively blocks external dust and debris from entering the device, preventing dust accumulation at the source. Compared to traditional fan-based devices, this significantly reduces maintenance frequency, making them particularly suitable for dusty industrial workshops, outdoor data stations, and similar environments.

3. Q: Does the fanless design of the QY-B5300, which supports 13th Gen Intel Core processors, adequately handle thermal demands under high load?

A: Absolutely. Both models utilize an aluminum alloy chassis as the core passive cooling medium. Through an optimized internal thermal conduction structure (combined with thermal pads and heat sinks), heat generated by the processor is rapidly transferred to the chassis exterior for dissipation. Even when the QY-B5300 runs a 13th Gen Core i7 processor under heavy workloads (e.g., industrial data processing, multi-task control), it maintains stable temperatures. This prevents performance throttling due to overheating, ensuring 24/7 continuous operation.

4. Q: Can special interfaces (e.g., RS485, HDMI 2.1) be customized for the QY-B5300 or QY-B5700?

A: Customization is supported. AMODE IPC offers interface customization services for both fanless mini PCs based on industry-specific requirements (e.g., multiple RS485 ports for industrial automation device coordination, HDMI 2.1 support for 4K high-refresh-rate displays in digital signage). Customized devices retain the reliability and sealing integrity of the original fanless design.

5. Q: What is the warranty period for both products? What is the after-sales process if a fault occurs?

A: Both QY-B5300 and QY-B5700 come with a 2-year full-unit warranty (extendable to 3 years for industrial-grade components). For device malfunctions, submit a request via the "After-Sales Support" section on our official website (https://www.amodeipc.com/) or contact customer service directly. Our support team will respond within 24 hours to provide remote troubleshooting guidance. For on-site repairs, we will coordinate the nearest service point based on your location to minimize equipment downtime in industrial settings.

6. Q: What specific power anomalies does the QY-B5700's overvoltage and overcurrent protection function address?

A: This feature addresses common industrial power fluctuations (e.g., transient voltage spikes or dips) and current overloads (e.g., sudden surges caused by external device short circuits). Upon detecting anomalies, the device automatically triggers protective mechanisms to cut off abnormal current/voltage inputs, preventing damage to core components (CPU, storage, power modules). It is particularly suitable for outdoor environments or industrial production lines with unstable power supplies.

Recommended